Whole vehicle wire harness corrugated pipe bidirectional pattern winding process

A corrugated tube and threading technology, which is applied in the field of two-way winding process of the vehicle's wiring harness corrugated tube, can solve the problems of side branch line harnesses that cannot be stably limited, missing winding, and uneven winding of corrugated tube tapes, etc., so as to avoid loosening of circuit connections or even The effect of breaking the circuit and ensuring the degree of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

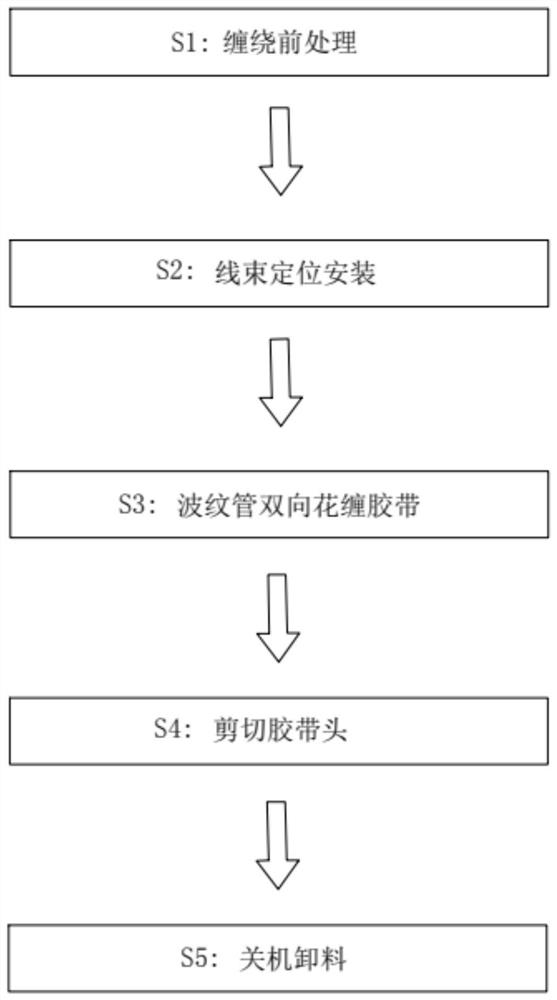

[0024] Such as Figure 1 to Figure 6 As shown in the figure, a two-way twisting process for a complete vehicle wiring harness corrugated tube includes the following steps:

[0025] S1: Pre-winding treatment: The tape-wrapping position of the vehicle harness includes cross-shaped or triangular branch nodes and branch lines. First, wrap the branch line positions at the end of the branch nodes on the harness with PVC / cloth tape for 2 tape widths, and then Install bellows on the wrapped tape to prevent scratching the wires;

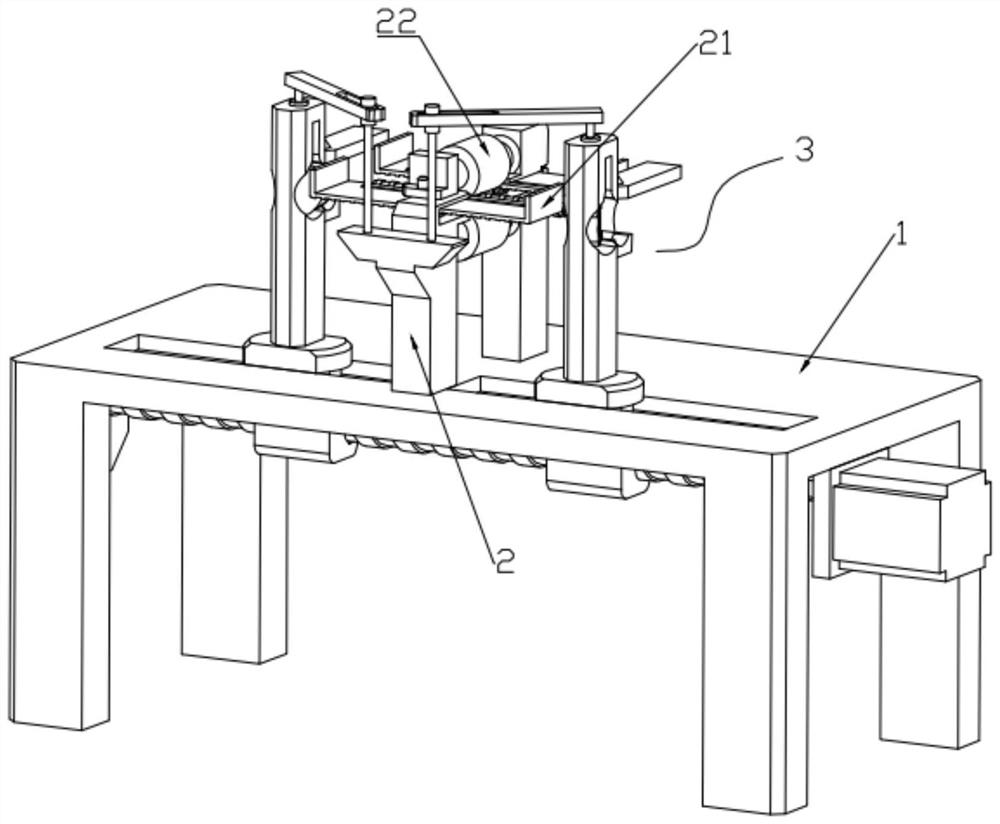

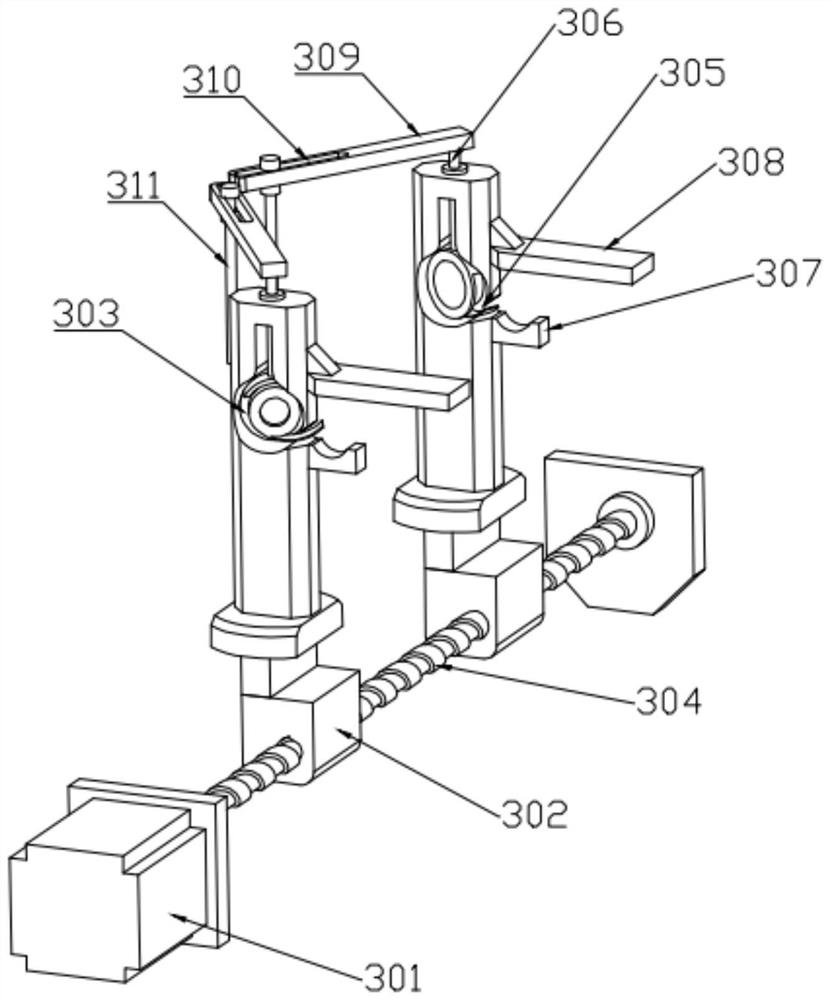

[0026] S2: Positioning and installation of wiring harness: install the wiring harness of the whole vehicle with bellows installed on the branch line on the positioning frame 2, and fix the positioning frame 2 with a snap joint, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com