Sidewall rubber composition and tire

A rubber composition and rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as noise and deterioration, and achieve the effect of improving passing noise and excellent low rolling resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074]The present disclosure is described in more detail below with reference to Examples. Note: The present disclosure is not limited to the following examples.

[0075]

[0076] Rubber compositions A and B for sidewalls were prepared according to the formulations listed in Table 1 using a general Banbury mixer. The blending amount of each component listed in Table 1 is the amount (parts by mass) relative to 100 parts by mass of the rubber component.

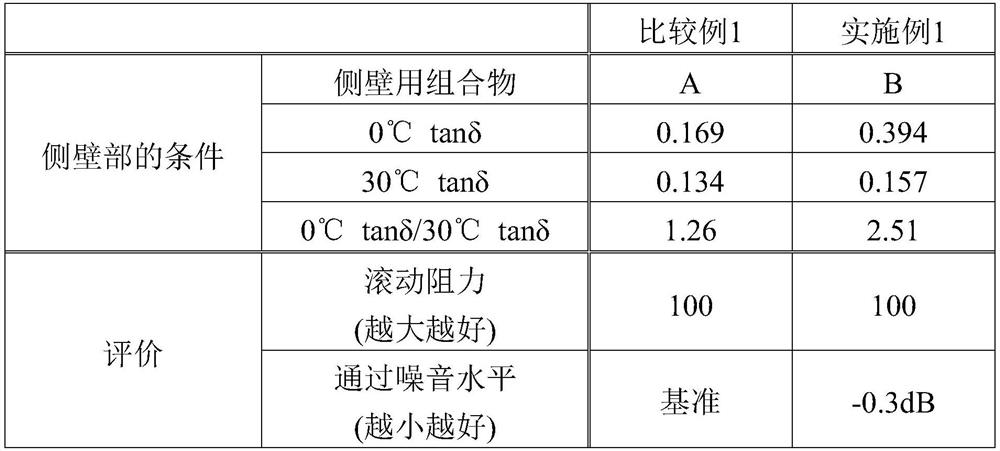

[0077] The obtained sidewall rubber compositions A and B were vulcanized at 160° C. for 15 minutes, and the loss tangent (tan δ) of the obtained vulcanized rubber at 0° C. and 30° C. was measured using a spectrometer manufactured by Ueshima Seisakusho Co., Ltd. Measured under the conditions of 2% initial strain, 1% dynamic strain and a frequency of 52 Hz. Table 2 lists the measured tan δ at 0°C and 30°C and the calculated 0°C tan δ / 30°C tan δ.

[0078] [Table 1]

[0079] Composition for side walls A B nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com