Partially hydrogenated terpolymer rubber with star block structure and its preparation method and application

A technology of terpolymerized rubber and terpolymer, which is applied in vehicle parts, tire parts, transportation and packaging, etc. It can solve the problems of safety restrictions, limited ability to adjust polymer structure, and small hysteresis loss at low temperature. Improvement of rolling resistance performance, excellent wet skid resistance, effect of amount reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

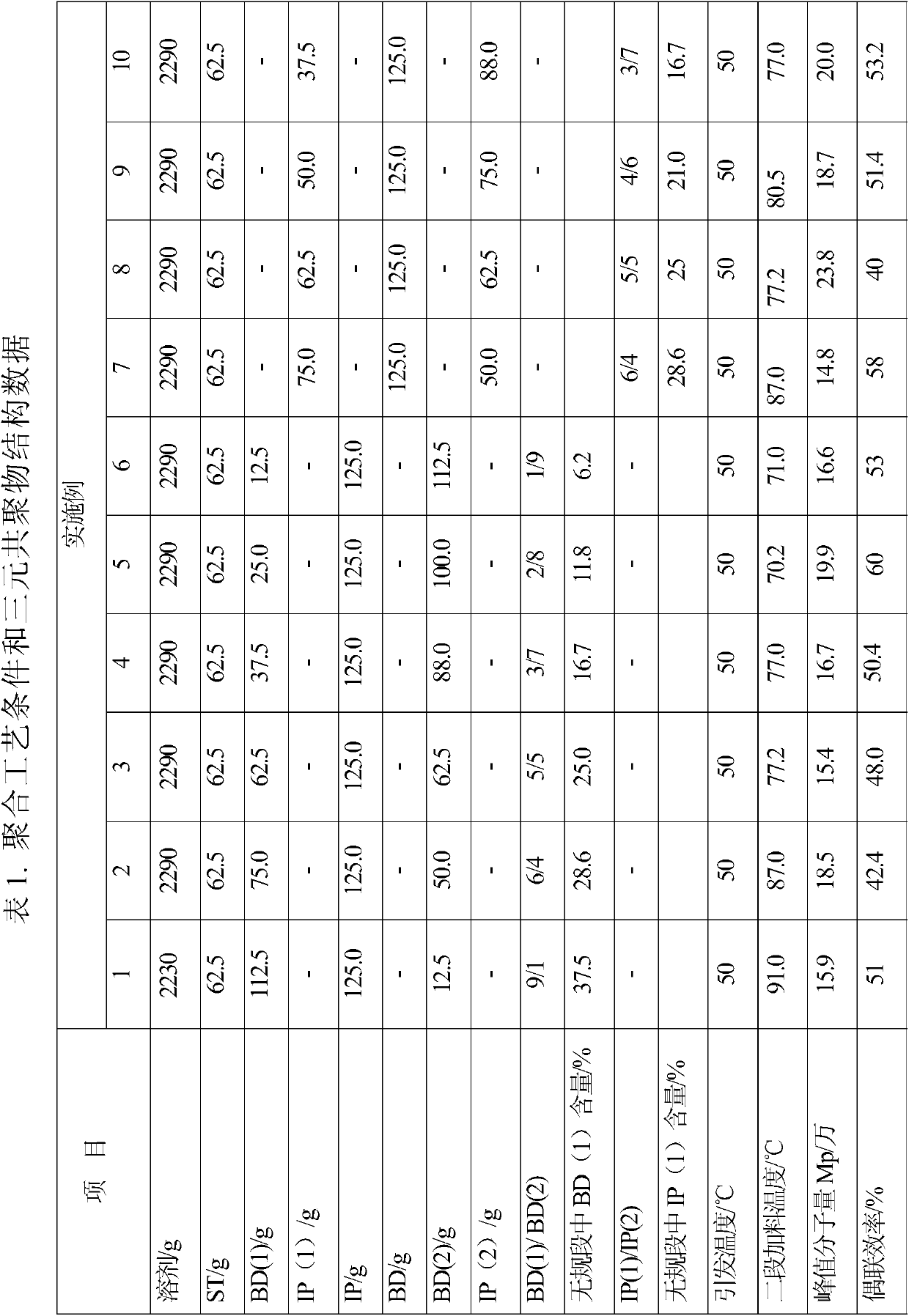

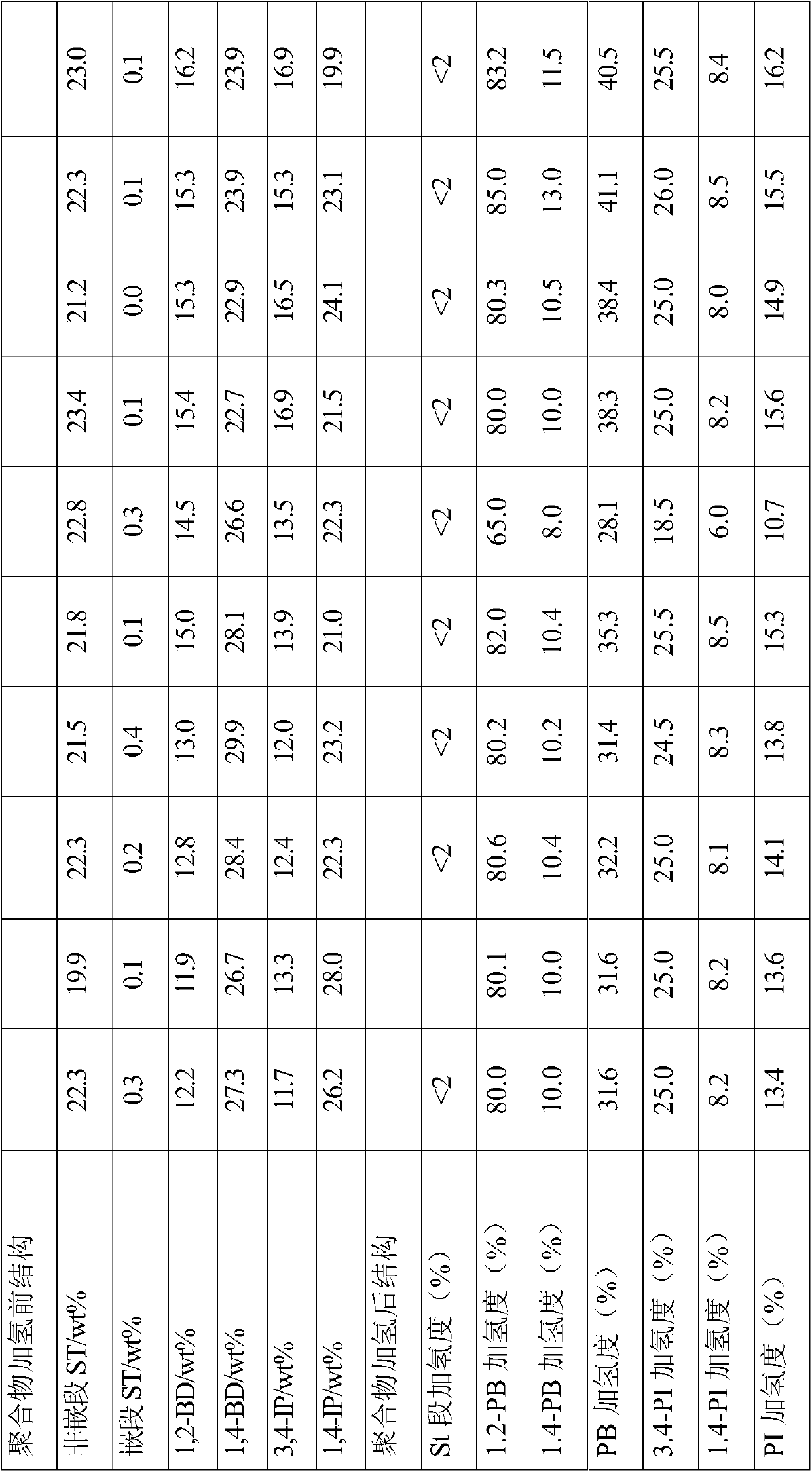

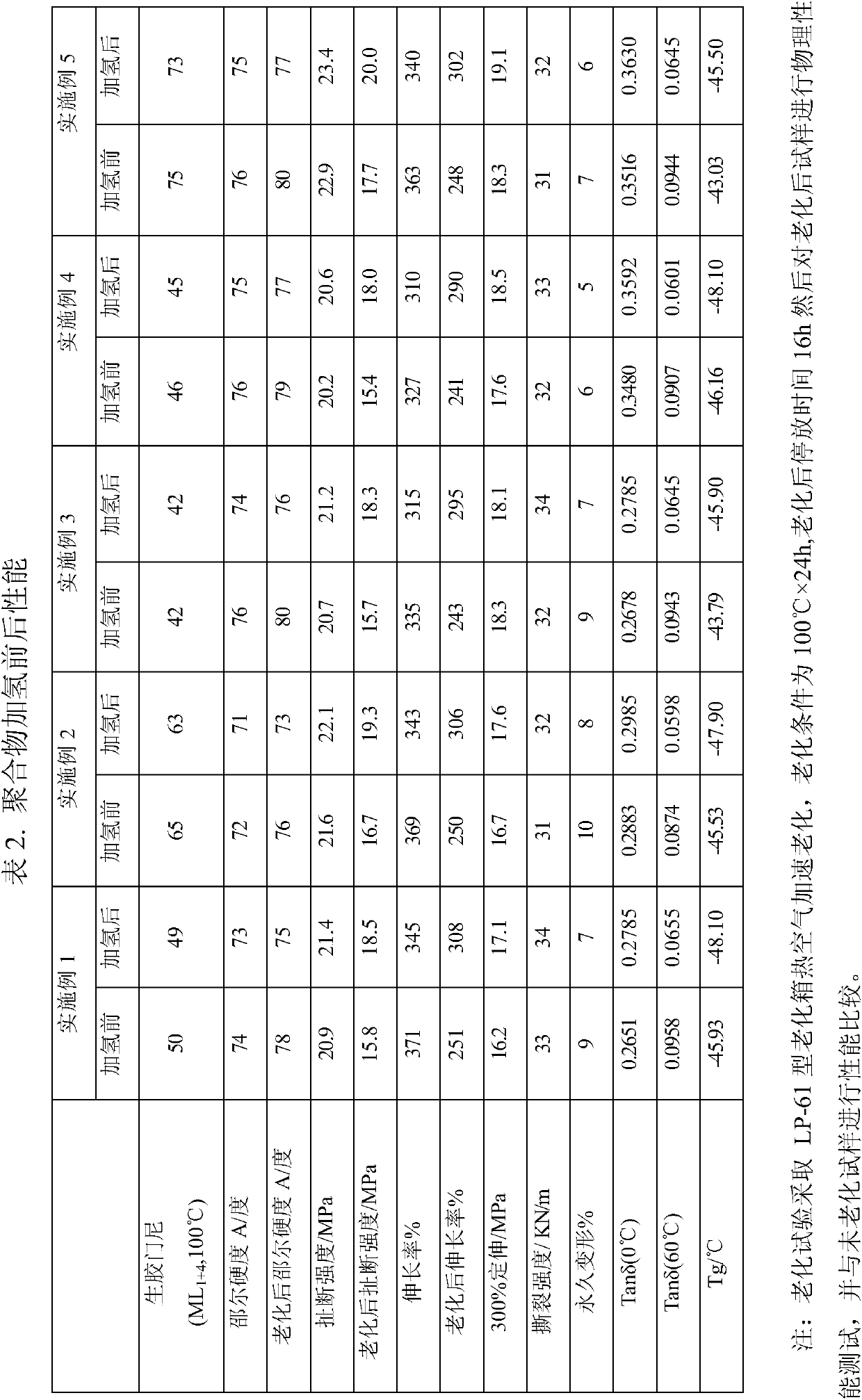

Embodiment 1

[0102] In a 5-liter stainless steel stirred tank under the protection of high-purity nitrogen, add 2230g cyclohexane, 62.5g styrene, 125g isoprene and 112.5g butadiene, then add 1.45mmol tetrahydrofurfuryl alcohol ethyl ether and 0.37mmol deca Sodium dialkylbenzenesulfonate, add 3.69mmol n-butyllithium at 50°C to initiate the reaction. After the polymerization is complete, add 12.5g of butadiene to continue the polymerization at 91°C. 0.4 mmol of tin tetrachloride was added, and after 70 minutes of reaction, 0.5 g of isopropanol was added to terminate the reaction.

[0103] In the stirring process, add a hydrogenation catalyst to the polymer solution to be hydrogenated after the above-mentioned termination, then feed hydrogen to carry out the hydrogenation reaction, the hydrogenation catalyst is a mixture of nickel naphthenate and triisobutylaluminum, wherein Al / The Ni molar ratio is 4:1, the catalyst dosage is 0.03gNi / 100g polymer to be hydrogenated, the reaction temperature...

Embodiment 2

[0106] In a 5-liter stainless steel stirred tank under the protection of high-purity nitrogen, add 2290g cyclohexane, 62.5g styrene, 125g isoprene and 75g butadiene, then add 1.35mmol tetrahydrofurfuryl alcohol ethyl ether and 0.34mol dodeca Sodium alkylbenzene sulfonate, add 3.42mmol n-butyllithium at 50°C to initiate the reaction, after the polymerization is completed, add 50g of butadiene to continue the polymerization at 87°C, react for 20 minutes and then add 0.34mmol of tin tetrachloride, after 70 minutes of reaction, 0.5g of isopropanol was added to terminate the reaction.

[0107] The process conditions for hydrogenation and hydrogenation catalyst removal are the same as in Example 1. Add 0.62g Irganox1520 to the obtained glue, coagulate with hot water, and dry with hot rollers. Test its structure and performance. The results are shown in Table 1 and Table 2. Show.

Embodiment 3

[0109] In a 5-liter stainless steel stirred tank under the protection of high-purity nitrogen, add 2290g cyclohexane, 62.5g styrene, 125g isoprene and 62.5g butadiene, then add 1.48mmol tetrahydrofurfuryl alcohol ethyl ether and 0.37mmol deca Sodium dialkylbenzene sulfonate, add 3.76mmol n-butyl lithium to initiate the reaction at 50°C, after the polymerization is completed, add 62.5g of butadiene to continue the polymerization at 77.2°C, react for 20 minutes and then return to the kettle 0.38 mmol of tin tetrachloride was added, and after 70 minutes of reaction, 0.5 g of isopropanol was added to terminate the reaction.

[0110] The process conditions for hydrogenation and hydrogenation catalyst removal are the same as in Example 1. Add 0.62g Irganox1520 to the obtained glue, coagulate with hot water, and dry with hot rollers. Test its structure and performance. The results are shown in Table 1 and Table 2. Show.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com