Conveyance apparatus, injection molding system, and control method

A technology of injection molding and delivery devices, which is applied in the field of injection molding systems and can solve problems such as long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present disclosure has several embodiments and relies on patents, patent applications, and other references for details known to those skilled in the art. Accordingly, when a patent, patent application, or other reference is cited or repeated herein, it should be understood that it is hereby incorporated by reference in its entirety for all purposes and for the viewpoints cited.

[0025] Referring to the drawings, arrow symbols X and Y in each figure indicate horizontal directions orthogonal to each other, and arrow symbol Z indicates a vertical (vertical) direction with respect to the ground.

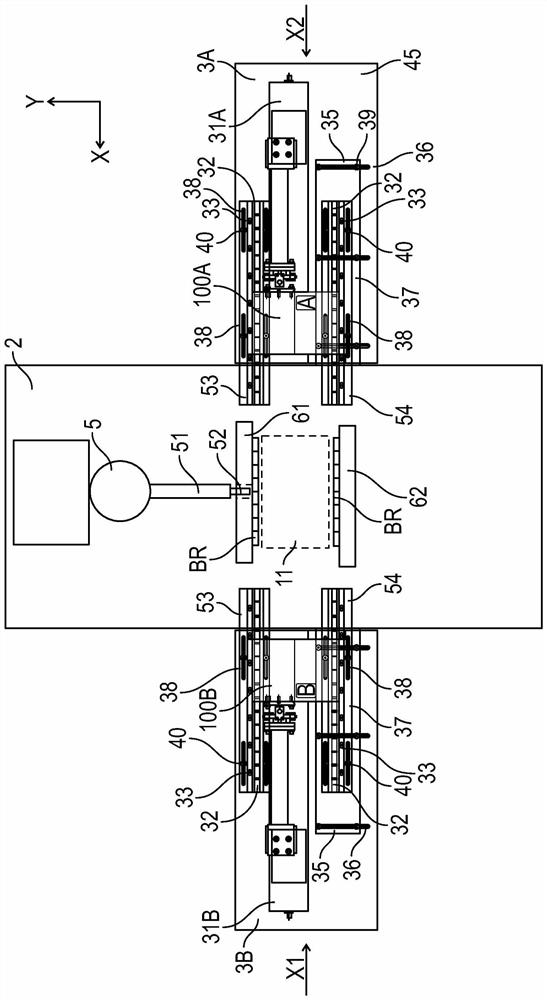

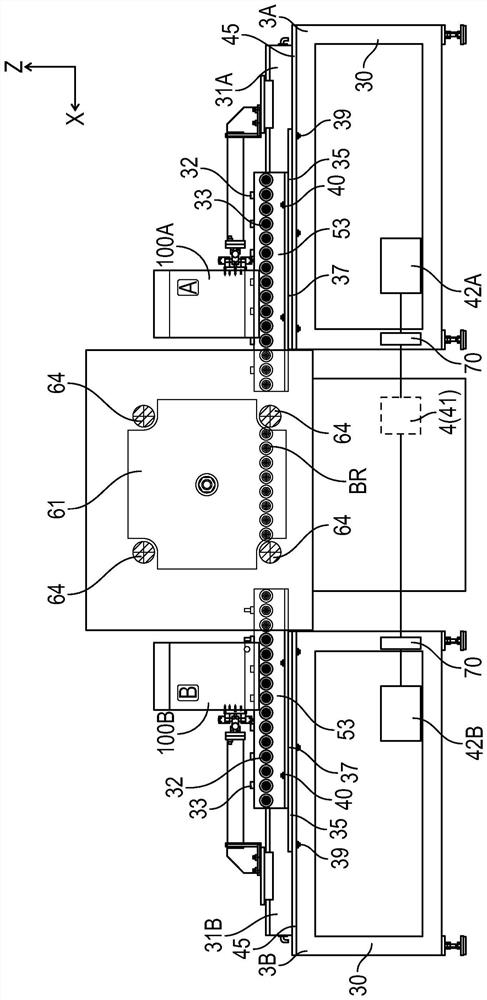

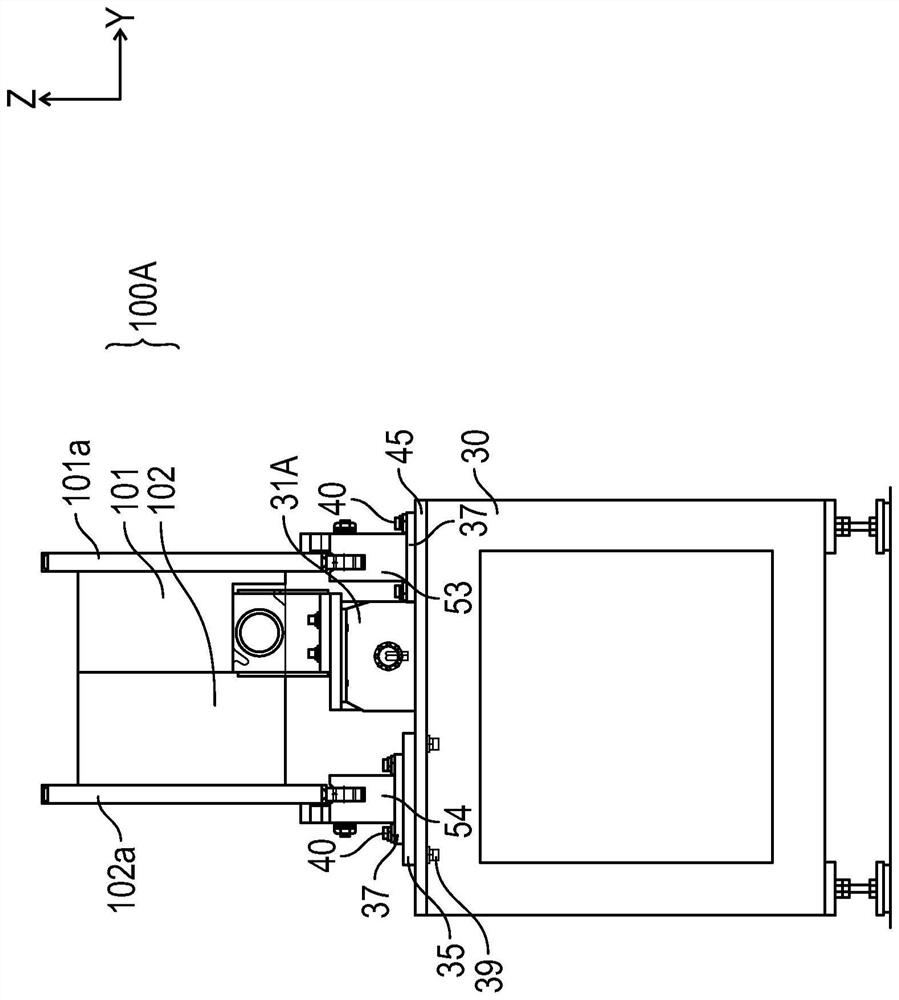

[0026] Figures 10, 11 and 3 illustrate the injection molding systems discussed in US2018 / 0009146 and Japanese Patent Publication No. 2018-001738 / VN20160002505 and are provided here for informational / descriptive purposes only. Figure 10 shows a top view of the injection molding system. FIG. 11 shows a cross-sectional view at line X1-X2 in FIG. 10 . Fig. 3 shows a side view ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com