Full-automatic sheet wiping machine

A wiping machine, fully automatic technology, applied in conveyors, conveyor objects, cleaning methods using tools, etc., can solve the problems of high labor intensity, low wiping work efficiency, secondary pollution, etc., and avoid secondary pollution. Pollution, realize automatic wiping, and improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

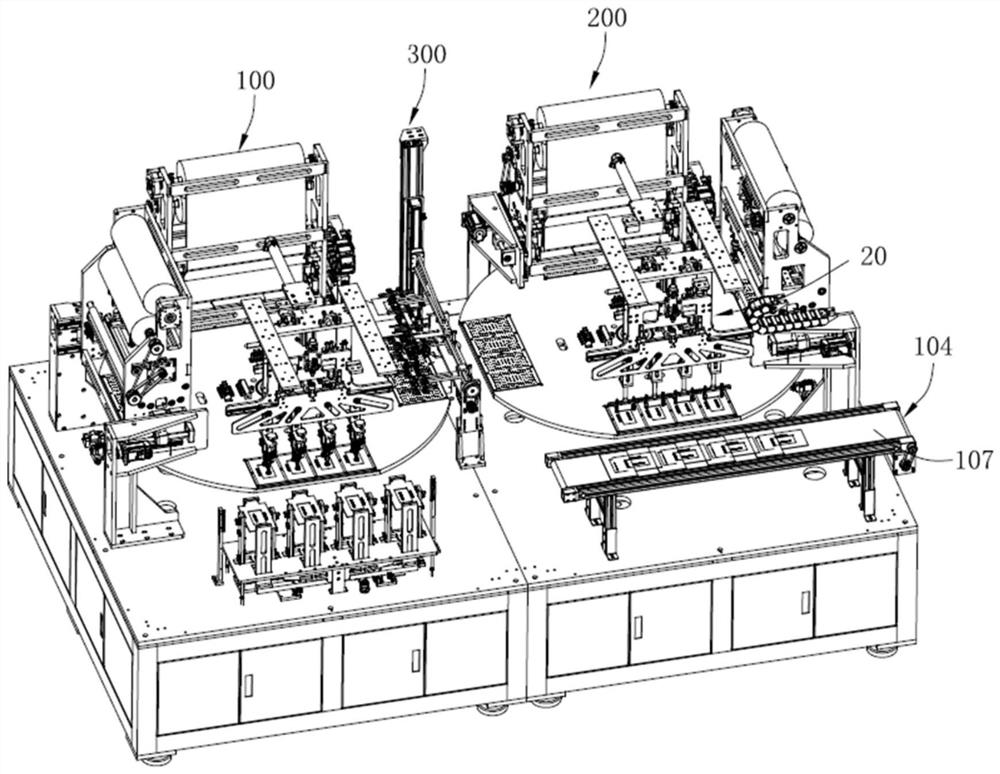

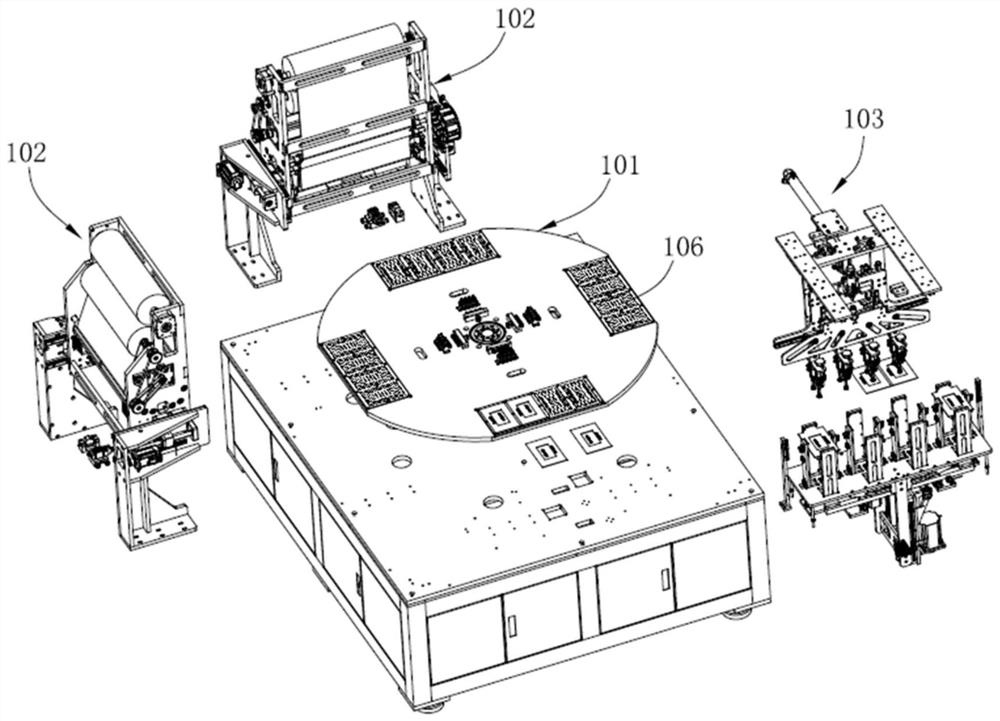

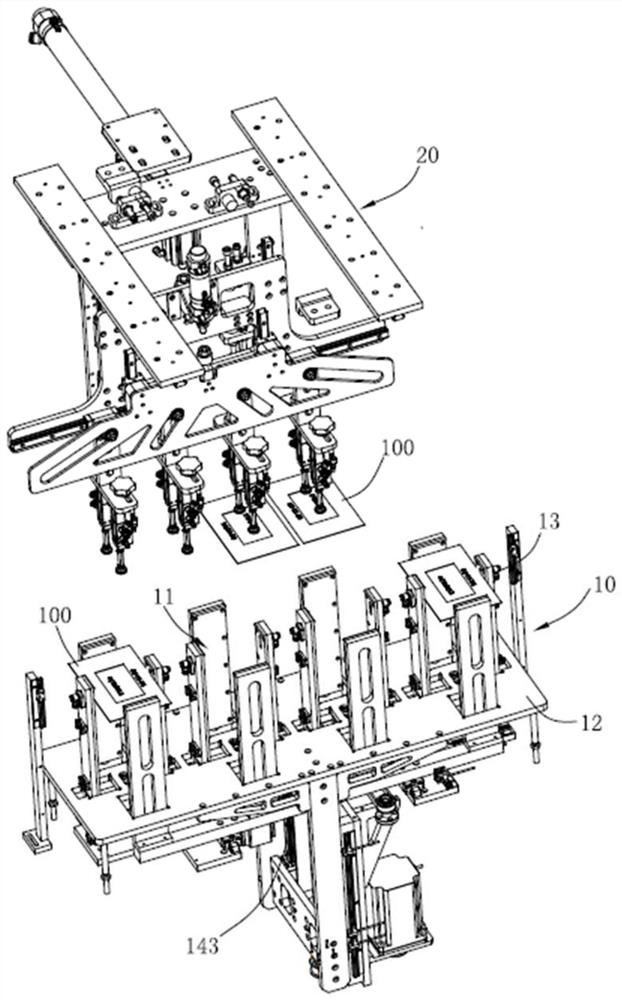

[0029] Such as Figure 1 to Figure 12 As shown, the present invention provides a fully automatic wiping machine, which includes a first wiping device group 100, a second wiping device group 200 and a turning device 300, and the turning device 300 is arranged on the second Between the first wiping device group 100 and the second wiping device group 200 . The first wiping device 100 group automatically wipes and cleans the front of the polarizer, the turning device 300 turns over the wiped polarizer, and rotates to the second wiping device group 200, the second wiping device Group 200 wipe cleans the reverse side of the polarizer.

[0030] The structure of the first wiping device group 100 and the second wiping device group 200 is basically the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com