Magnetic drive system and method combining permanent magnet array and double coil

A permanent magnet array and magnetic drive technology, applied in the field of magnetic control, can solve the problems of large amount of control, high energy consumption, complex device structure, etc., and achieve the effects of reducing structural complexity, reducing heat dissipation pressure, and reducing driving power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

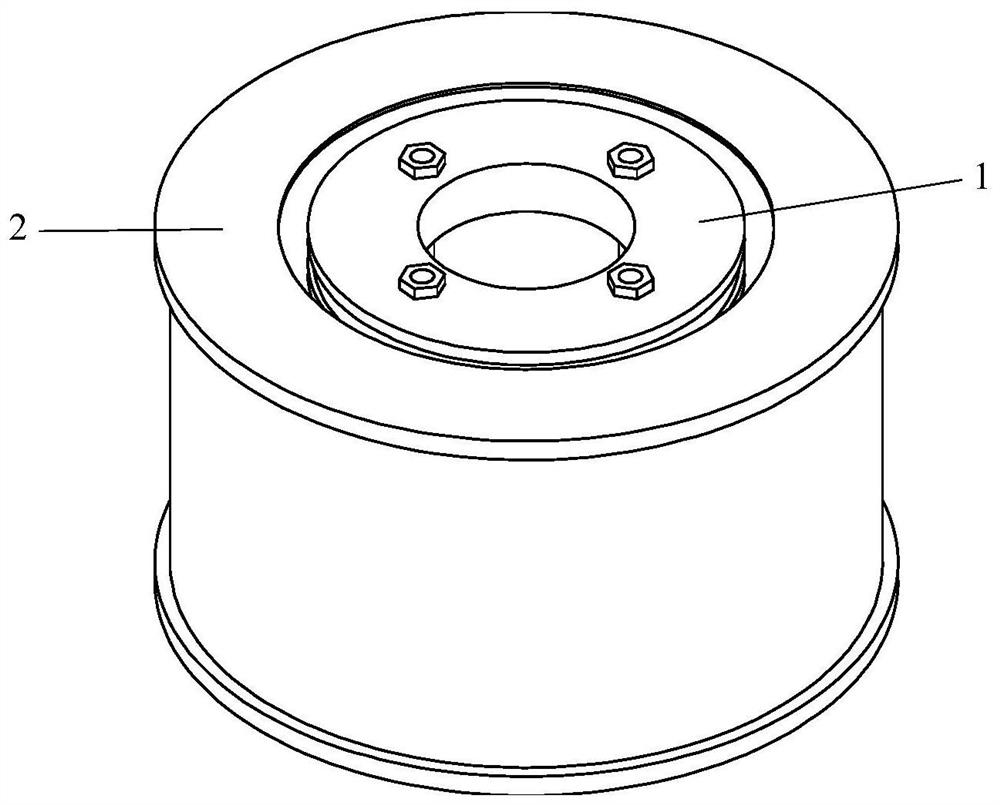

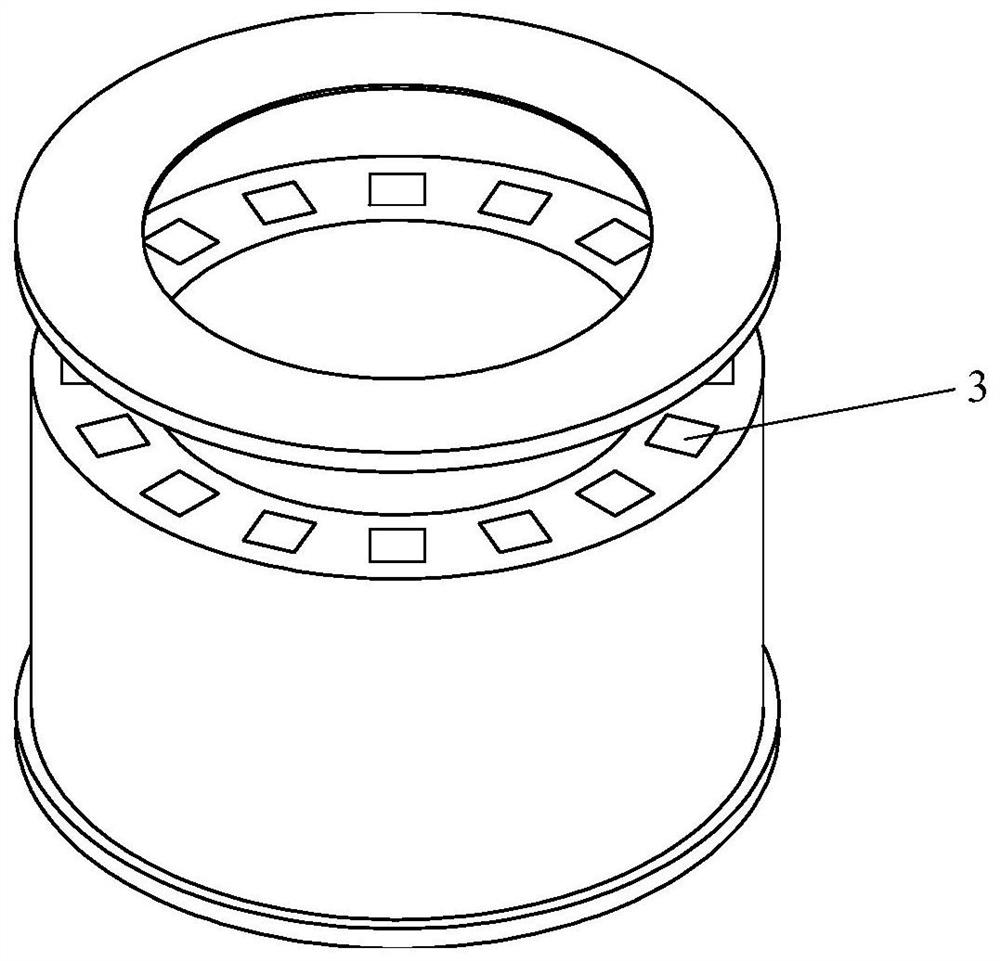

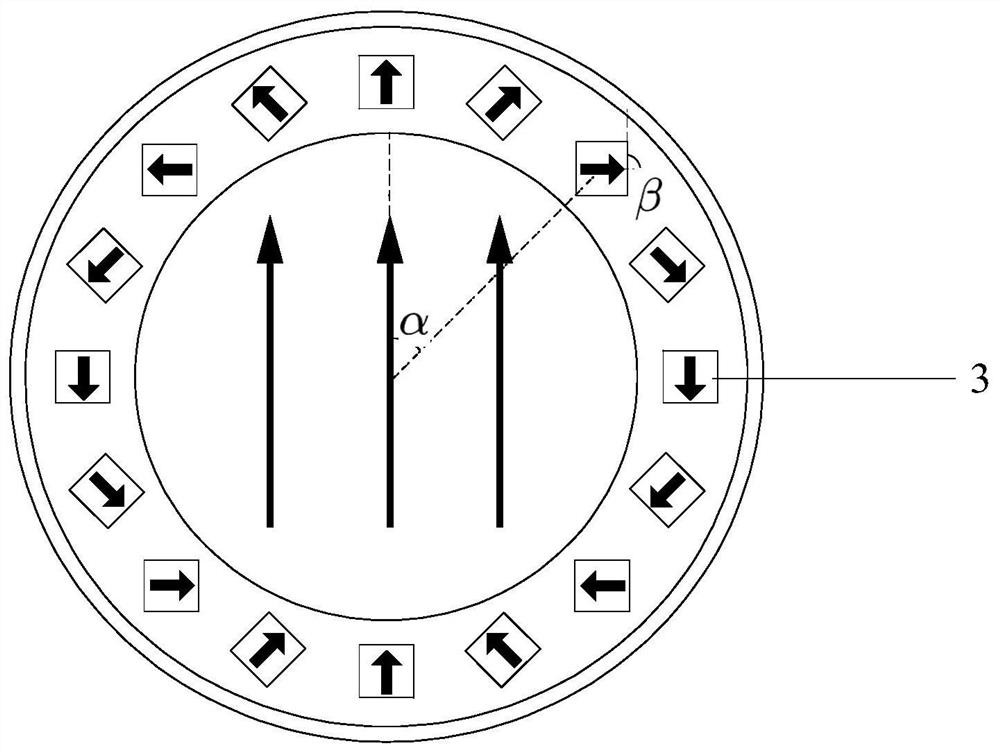

[0055] figure 1 It is a schematic diagram of the overall structure of the system in this embodiment. The two parts of the system: the Halbach ring array and the Maxwell coil are coaxially placed to achieve a relatively simple control method, that is, to rotate the whole system to change the orientation of the controlled object, and then to Maxwell When the coil is energized, the controlled object can move along the direction; the controlled object should be placed at the center of the system, that is, at the center of the axis, at a position whose height is half the height of the system; the Maxwell coil placed in this way is at the center, and the diameter A magnetic field gradient that meets the requirements will be generated on the tangent surface, so that the direction of the propulsion force is consistent with the direction of the magnetization; making the radius of the Halbach ring array larger than the radius of the Maxwell coil can make the magnetic field and magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com