Sensor assembly

A sensor component and sensor technology, applied in the direction of central heating sensors, instruments, cooking utensils, etc., can solve the problems of insufficient measurement, hindering normal functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

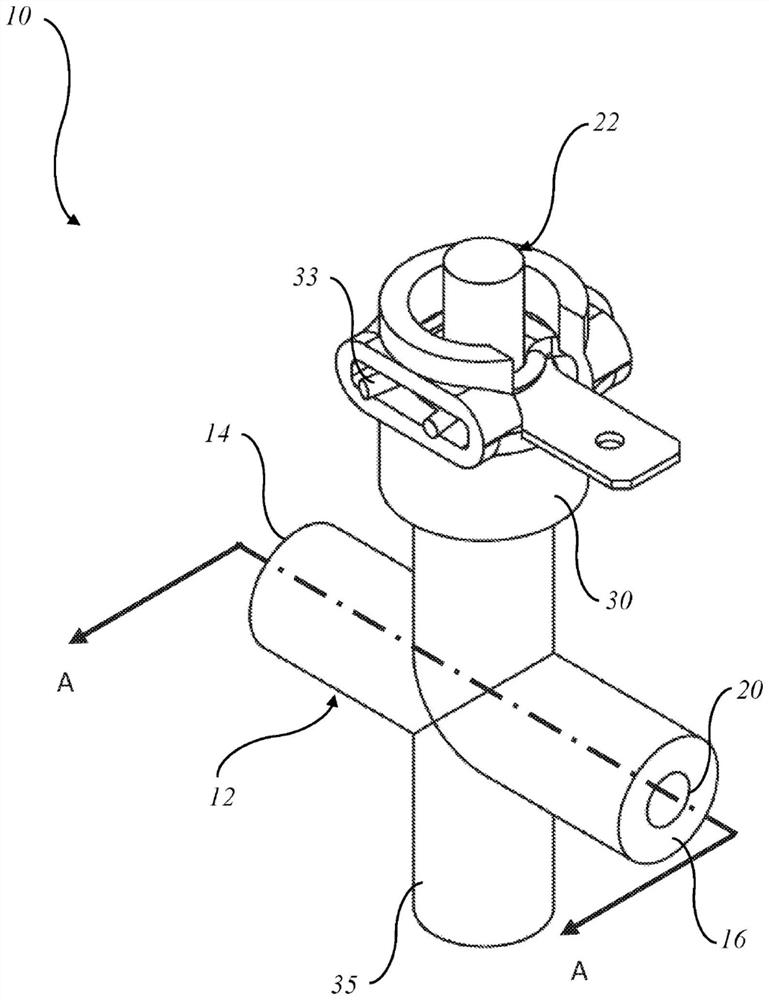

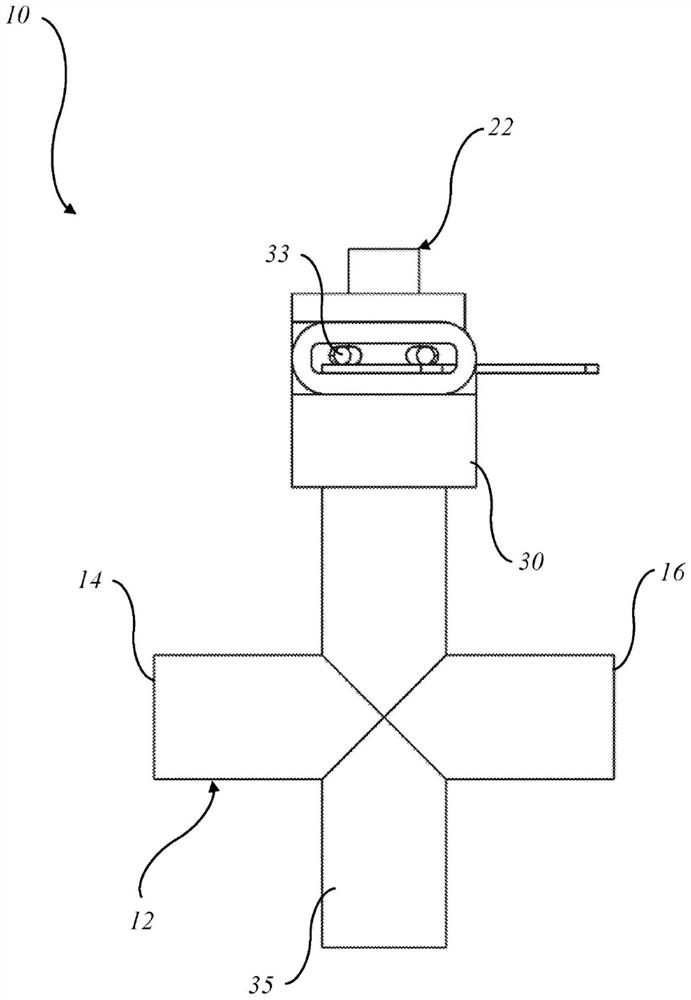

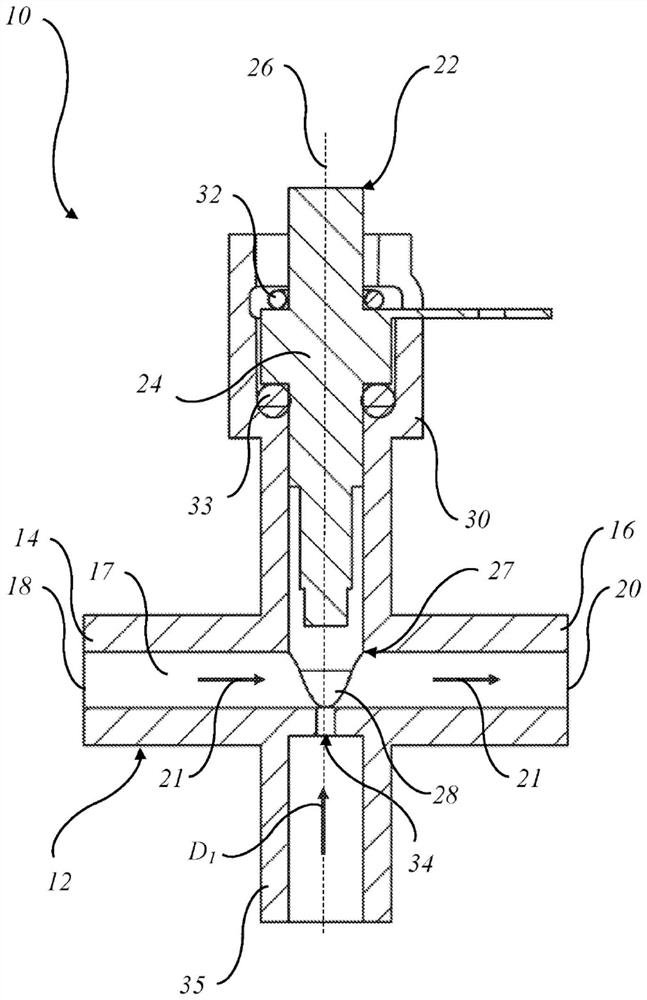

[0040] First refer to the attached Figure 1 to Figure 3 , schematically depicts a sensor assembly 10 for an appliance 100 , 200 . The appliance 100, 200 is configured to heat a liquid, such as water, to make a beverage, such as coffee.

[0041] The assembly 10 includes a conduit in the form of a tube 12 having longitudinally opposed first and second ends 14 and 16 . like image 3 As shown, tube 12 has an inlet 18 adjacent first end 14 and an outlet 20 adjacent second end 16 . Tube 12 has a longitudinal sidewall 17 extending between an inlet 18 and an outlet 20 to provide a liquid flow path 21 extending linearly between first end 14 and second end 16 .

[0042] The assembly 10 also includes a sensor 22 for measuring line parameters (eg, temperature, pressure, flow, clarity, etc.) of the liquid flowing along the path 21 . In a preferred embodiment, the sensor 22 is an NTC type sensor configured to measure the temperature of the liquid.

[0043] The sensor 22 has a body 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com