Adjustable center tool apron for numerical control turning machining and using method thereof

A technology for adjusting the center and the tool holder, applied in the field of adjustable center tool holder, it can solve the problems of many styles, affecting the production efficiency of the product, long correction time, etc., and achieve the effect of correcting the coincidence of the rotation center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

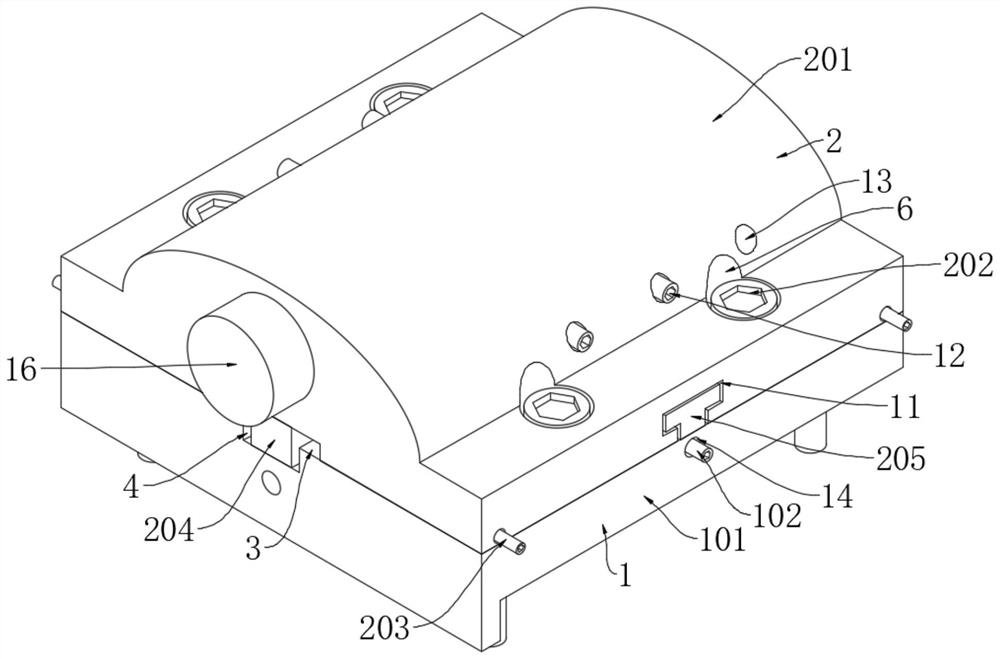

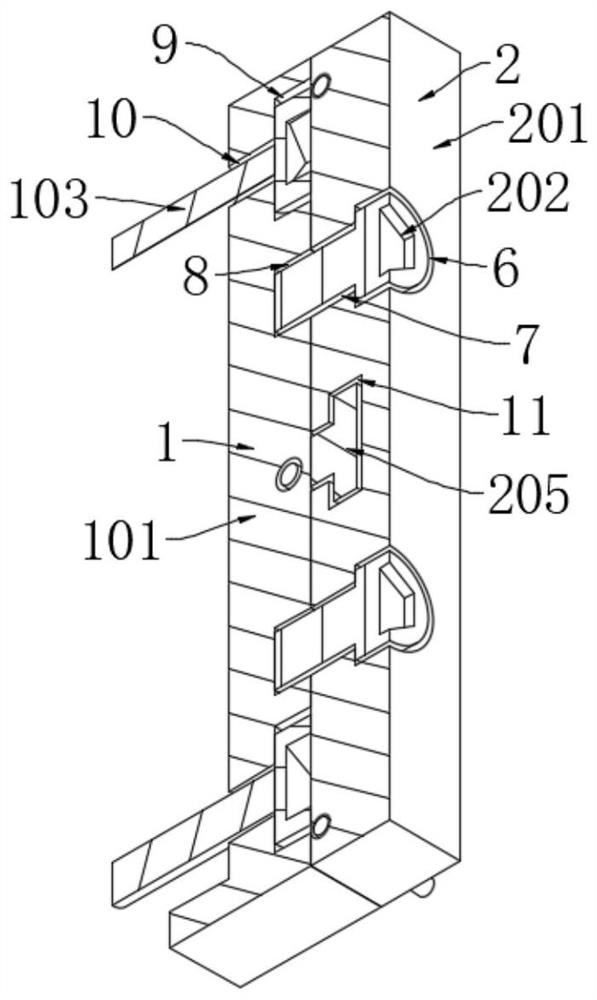

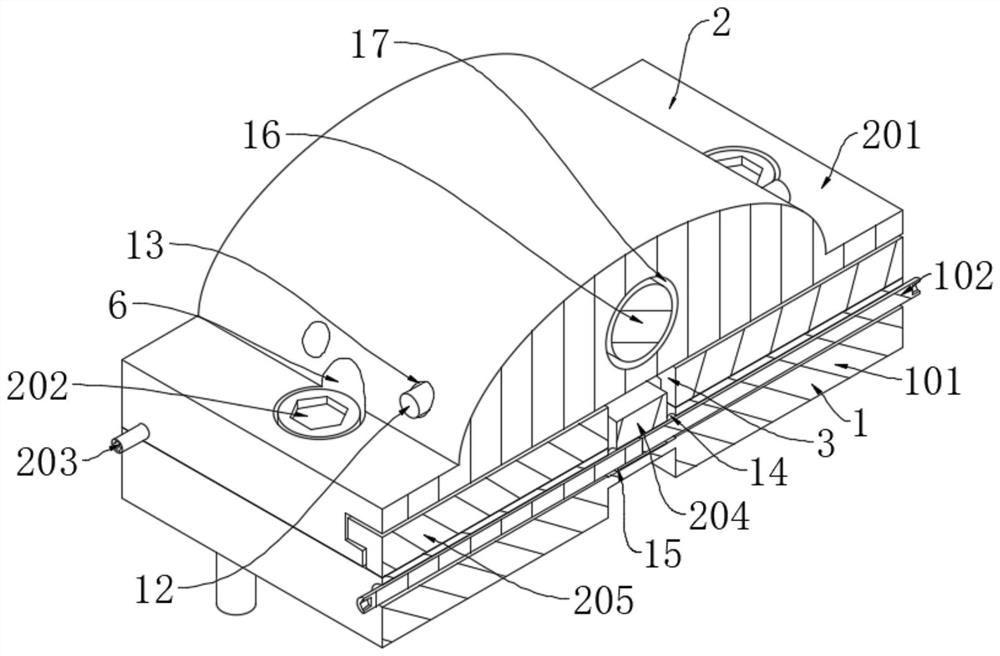

[0030] see Figure 1-5 , the present invention provides a technical solution: an adjustable center tool holder for CNC turning, including a main body assembly 1 and an adjustment and fixing assembly 2, the main body assembly 1 includes a tool holder main body 101, a limit block fixing screw 102 and a tool holder Fixing screw 103;

[0031] An adjustment and fixing assembly 2 is installed on the upper surface of the main body assembly 1;

[0032] The adjustment and fixing assembly 2 includes a floating knife seat body 201, a floating knife seat fixing screw 202, a floating knife seat adjusting screw 203, a limit block body 204 and a T-shaped slider 205;

[0033] The upper surface of the tool seat main body 101 is provided with a second groove 4, the lower surface of the second groove 4 is attached to the outer side wall of the stopper body 204, and one side of the tool seat main body 101 is provided with a fifth threaded through hole 14 The outer wall of the limiting block bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com