Intermediate support device for ultra-deep drilling borehole

A technology of intermediate support and support device, which is applied in the direction of shaft equipment, earthwork drilling, mining equipment, etc., can solve the problems of increasing the production cost of the shaft and increasing the cost of the shaft, so as to increase the effective circle diameter, improve the vertical stability, Guarantee the effect of verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

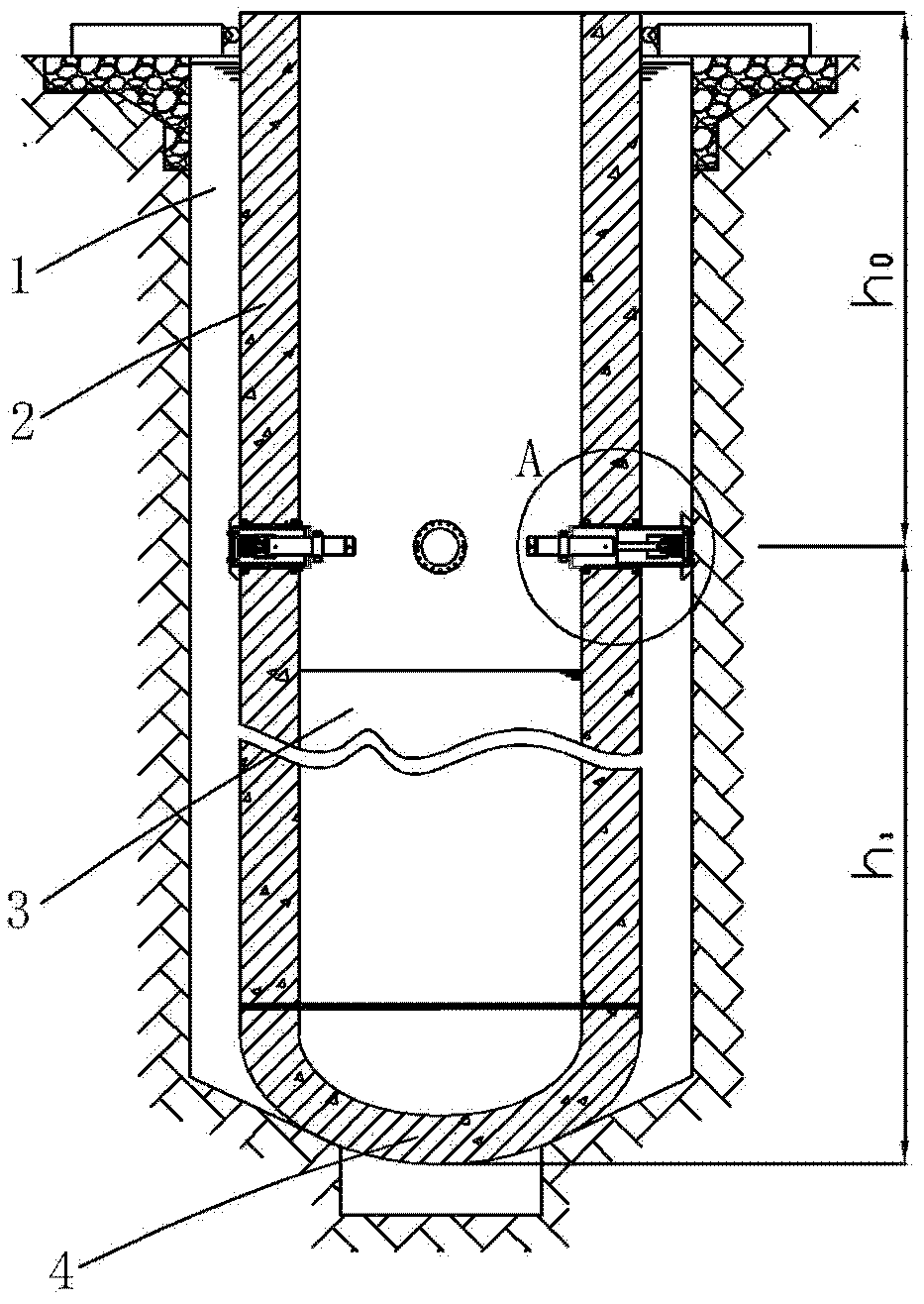

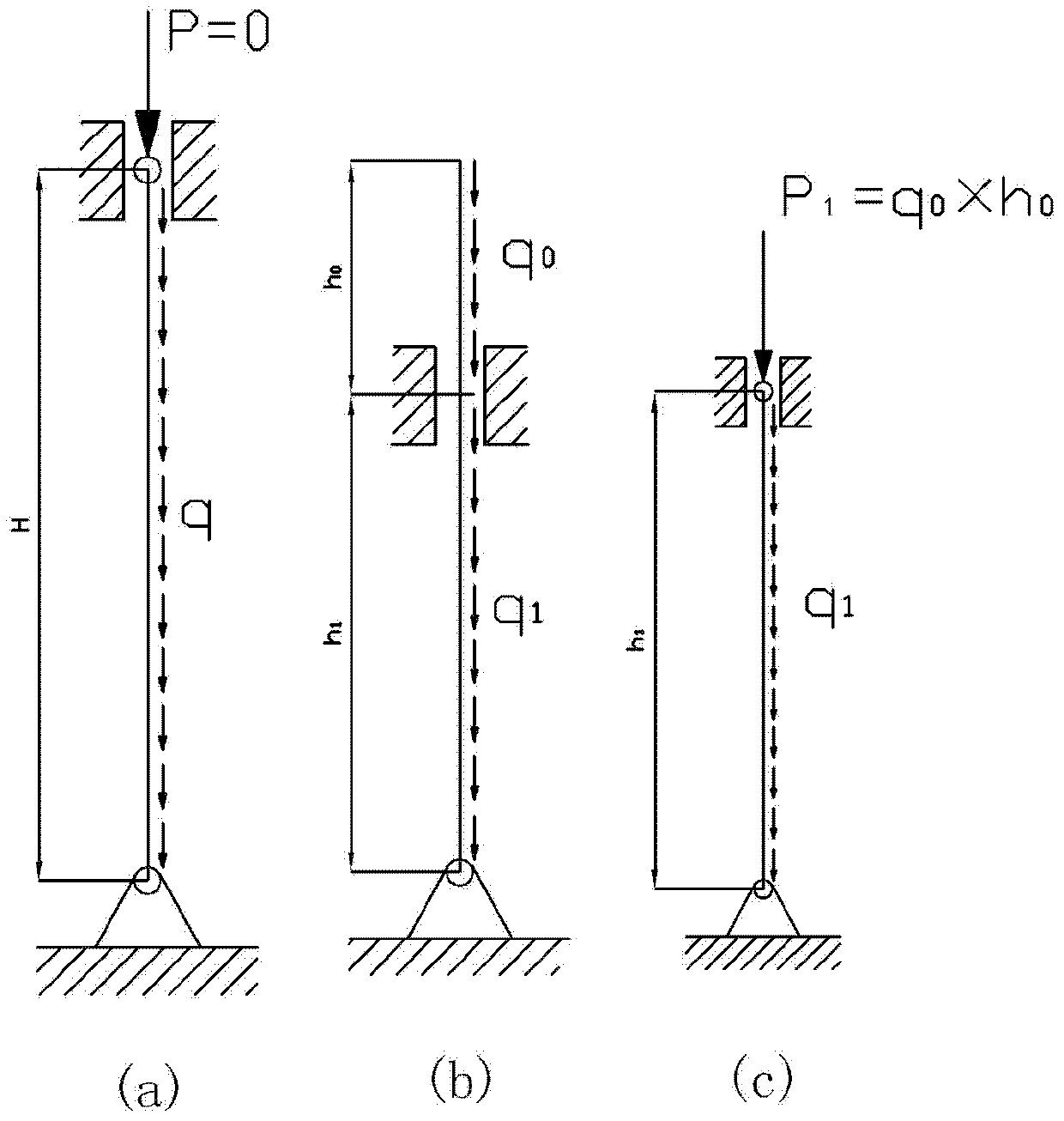

[0020] Example: Combine Figure 1-4 , the ultra-deep drilling wellbore intermediate support device of this embodiment includes:

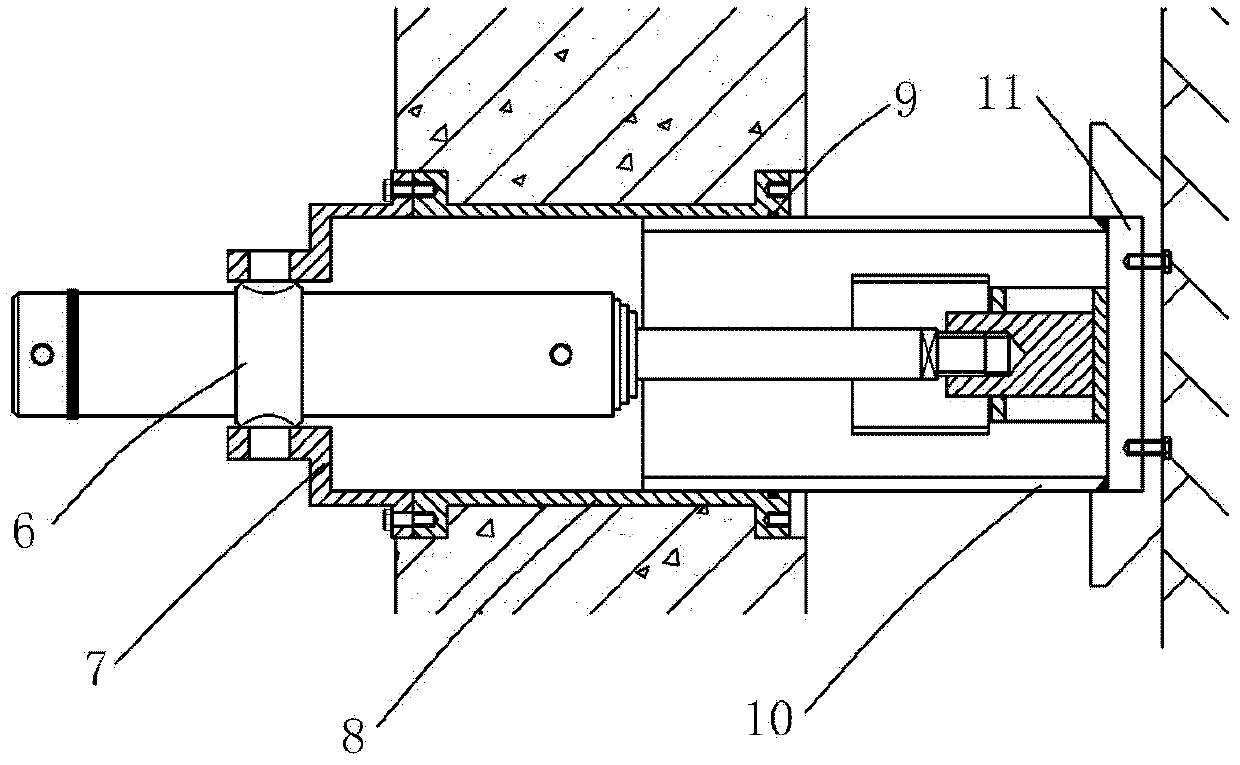

[0021] The pre-embedded tube 8 pre-buried in the wellbore wall, the pre-buried tube 8 is arranged along the radial direction of the wellbore and the two ends pass through the inside and outside of the wellbore wall, and a connecting flange is provided on the end of the pre-buried tube 8 facing the inner cavity of the wellbore The connecting flange is connected with the oil cylinder support 7 with bolts and nuts, and the hydraulic cylinder 6 is arranged on the oil cylinder support 7; a cylindrical sliding shoe 10 is coaxially arranged in the embedded tube 8, and the outer circumference of the sliding shoe 10 An O-ring 9 is provided for sealing with the inner wall of the shaft, and a sealing flange 11 is provided at the outer end of the sliding shoe.

[0022] In the specific setting, the axis of the piston rod of the hydraulic cylinder 6 coincides wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com