Center line positioning device for device for quickly giving drilling azimuth angle and using method

A technology of positioning device and azimuth angle, which is applied to measuring device, active optical measuring device, measuring angle and other directions, can solve the problems of inaccurate drilling setting, affecting compass accuracy, and inaccurate drilling and centerline setting. , to avoid the wrong drilling position, easy to operate, and simple to adjust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059]Implementation example 1: A centerline positioning device for quickly specifying the drilling azimuth angle device, including a fixed plate 201 and a first laser 202, the first laser 202 is arranged on the fixed plate 201, and the central axis of the first laser 202 Vertical to the front surface of the fixed plate 201; also includes: a calibration table 204, the calibration table 204 is welded on the top of the fixed plate 201, the upper surface of the calibration table 204 is perpendicular to the front surface of the fixed plate 201; a first level 205, the first The level 205 is arranged on the upper surface of the calibration platform 204 .

[0060] Further, it also includes: supporting feet 203 , including three supporting feet 203 , the supporting feet 203 are connected to the fixing plate 201 , and the supporting feet 203 are evenly distributed around the central axis of the first laser 202 .

[0061] Further, the supporting foot 203 includes: a fixing nail 2032, on...

Embodiment 2

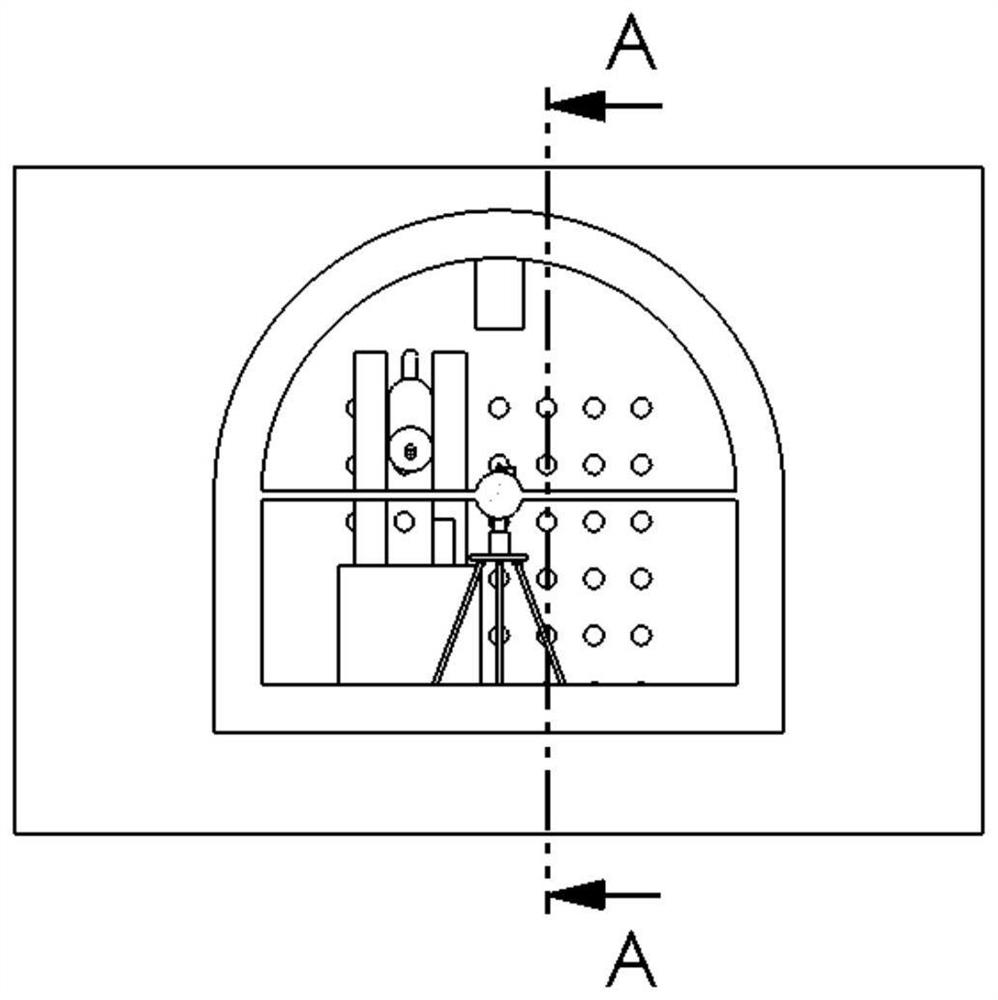

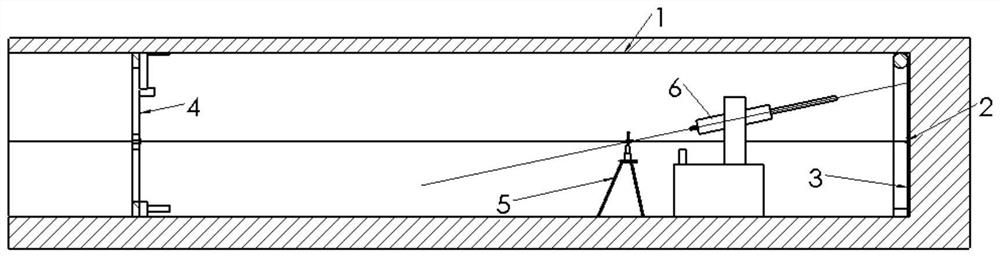

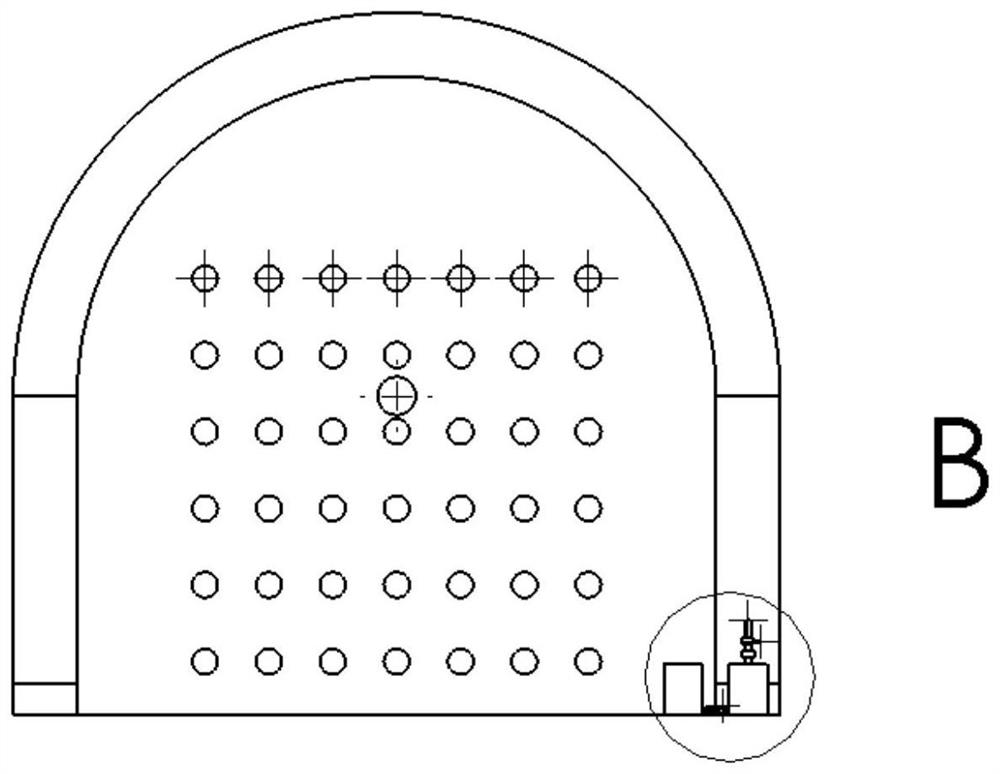

[0070] Implementation Example 2: In this embodiment, a device for rapidly setting the azimuth angle of a borehole, the device includes: an orifice positioning device 3, the orifice positioning device 3 is detachably installed on the working surface, and the orifice positioning device 3 A rectangular array 303 of circular holes with 6 rows and 7 columns is arranged on the top; a centerline positioning device 304, the centerline positioning device 304 includes a fixed plate 201 and a first laser 202, the first laser 202 is arranged on the fixed plate 201, the first The central axis of the laser 202 is perpendicular to the front surface of the fixed plate 201; the intersection positioning device 5, the intersection positioning device 5 includes a distance meter 507, a first frame body and an intersection positioning hole 506, and the intersection positioning hole 506 is arranged on the first frame body Above, the rangefinder 507 is arranged on the first frame body; the drill rod g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com