Battery holder for tiered battery packs

A technology for battery brackets and battery packs, applied in the direction of battery/battery traction, battery pack components, batteries, etc., which can solve the problems of laborious battery pack costs and unsuitable battery layered installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

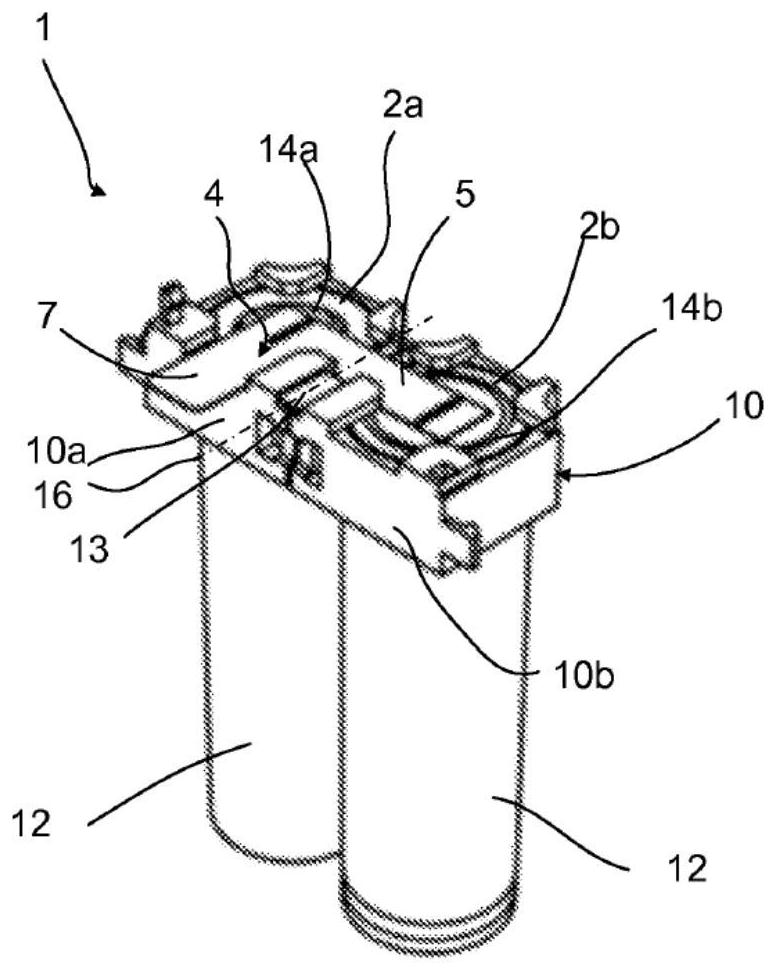

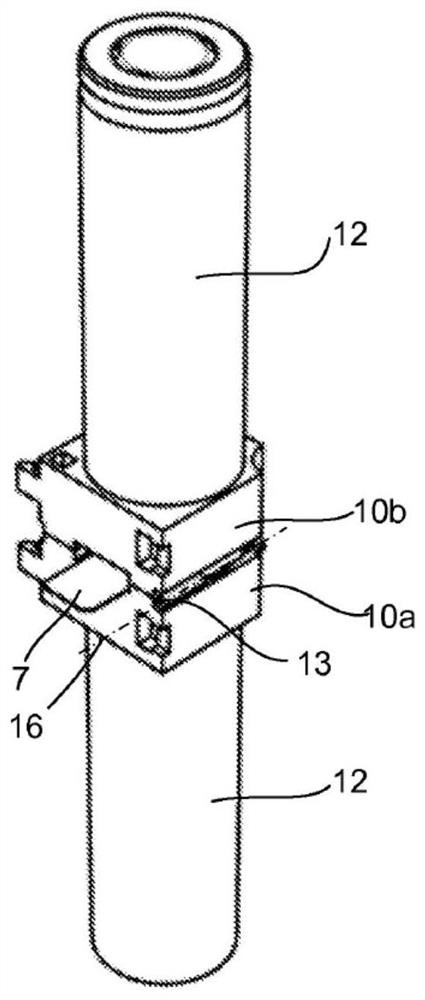

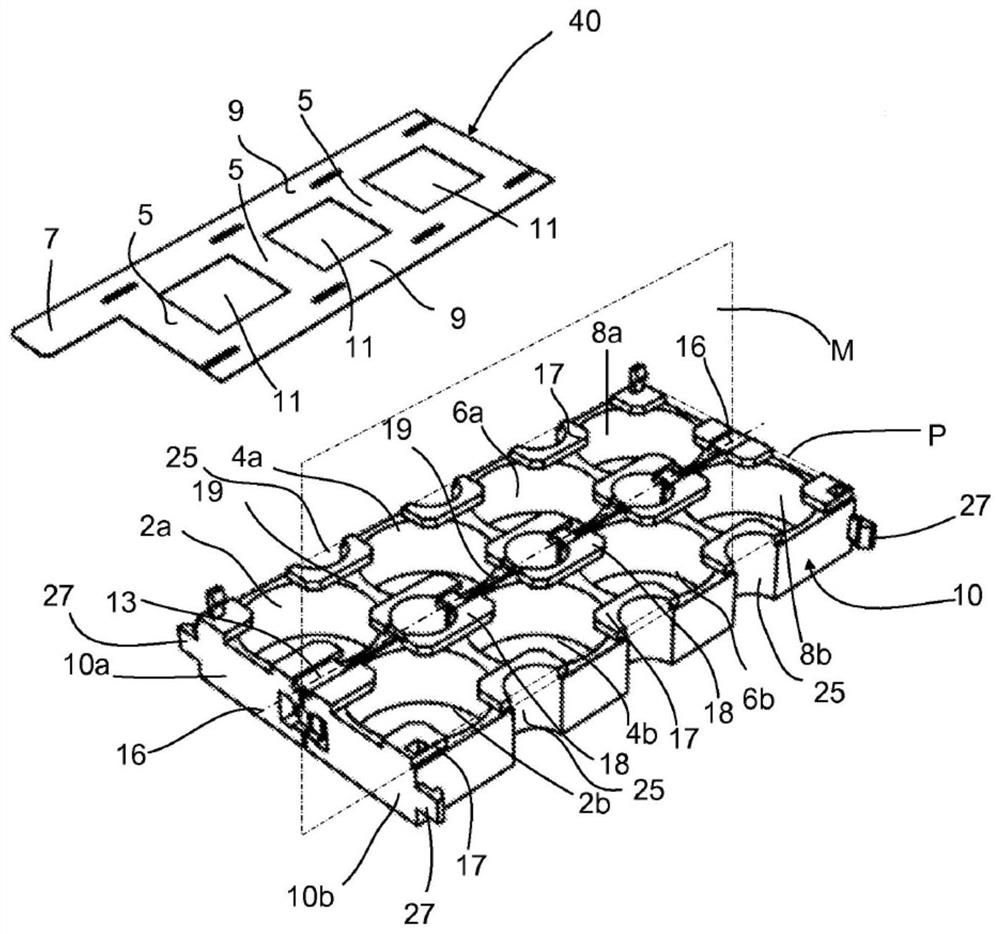

[0048] Figure 1a Shown is a battery holder 10 made in the form of a plate with two adjacent through-holes 2a, 2b made in the thickness of the plate. The plate is produced, for example, by molding or injecting a plastic material of the styrene polymer type, such as ABS (acrylonitrile butadiene styrene), which is an electrically insulating, flame-retardant material. Figure 1a Also shown are two cylindrical batteries 12 held vertically in place by the bracket 10, each battery 12 inserted through one of its ends into a respective hole 2a, 2b of the bracket 10, the longitudinal axis of each battery 12 perpendicular to the plane P of the plate ( figure 2 ). Bracket 10 also comprises connecting elements 4, which are metal sheets, such as nickel or copper, that come into contact with the electrical terminals of battery 12, preferably by welding the metal sheets to the battery's terminals. exist Figure 1a In the embodiment shown, one battery is mounted in hole 2a with its positive...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap