Dragging unfolding type high-rigidity stretching arm with high spatial folding-unfolding ratio

A folding aspect ratio and unfolding technology, which is applied to space navigation equipment, space navigation aircraft, aircraft and other directions, can solve the problems of increasing the complexity and volume of the driving mechanism, unable to adapt to the deployment of large-scale extension arms, and low driving efficiency. , to reduce the carrying capacity, improve the deployment efficiency, and achieve the effect of high driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

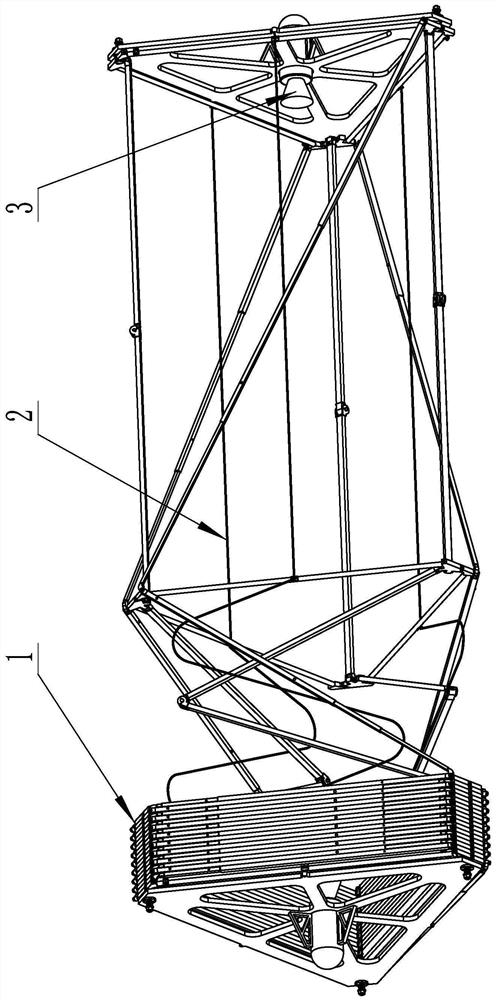

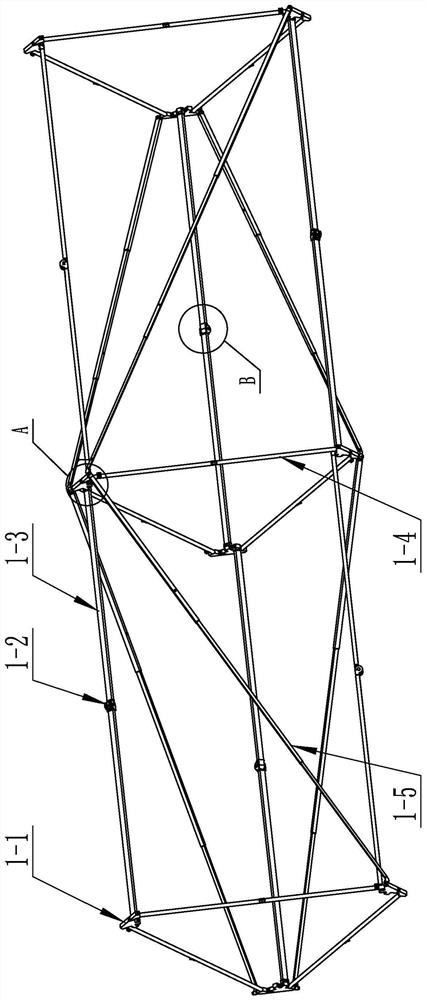

[0027] Such as Figure 1-Figure 2 As shown, the high-fold-expand-ratio drag-and-drag high-rigidity extension arm of this embodiment includes a foldable unit group 1, an axial catenary cable 2, a deployed jet engine 3 and an end bearing plate 4;

[0028] The two deployed jet engines 3 are respectively fixed on two end bearing plates 4, and a foldable unit group 1 is arranged between the two end face bearing plates 4, and the foldable unit group 1 includes N hinged in series. The foldable unit 1-0 is a positive integer of N≥1, and the two outermost foldable units 1-0 are fixedly connected to the two end bearing plates 4 respectively;

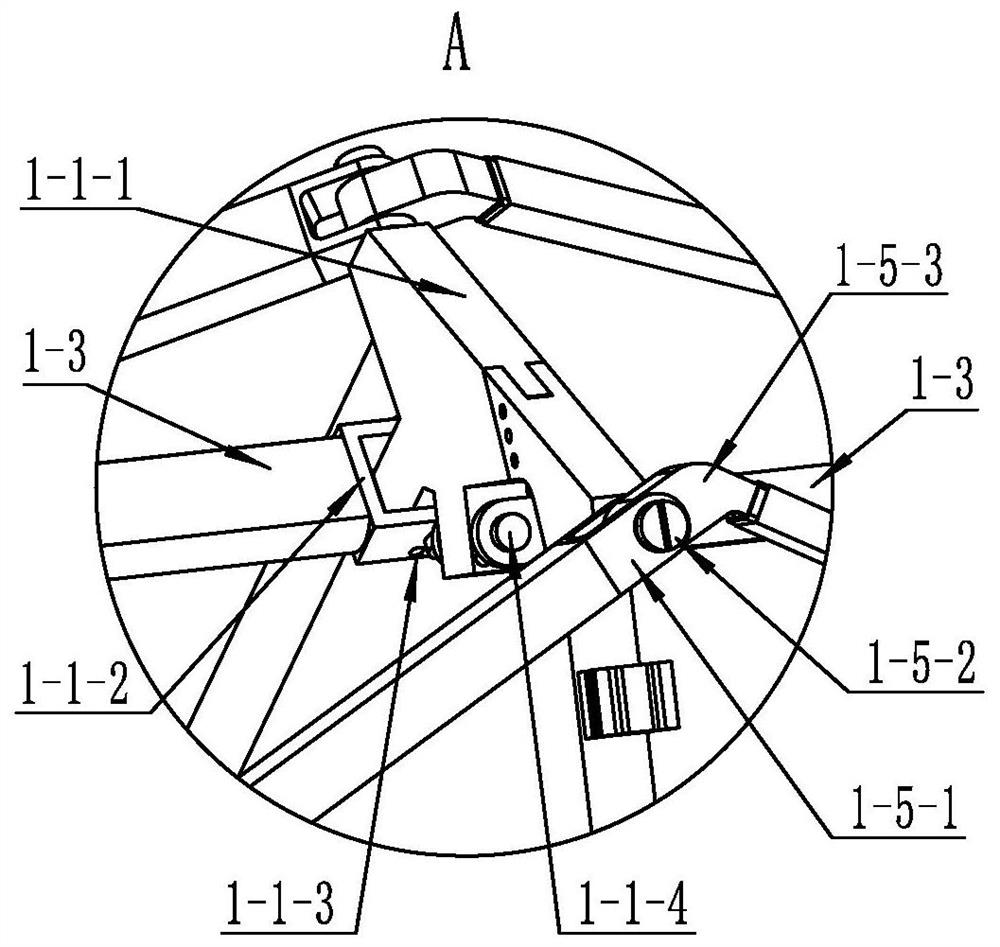

[0029] Each expandable unit 1-0 becomes a triangular prism after unfolded, and a telescopic rod 1-5 is hinged diagonally on each side of the triangular prism. Stretching, folding and shrinking, the three axial catenary cables 2 respectively span the sides corresponding to the N foldable units 1-0, and are radially limited, and the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com