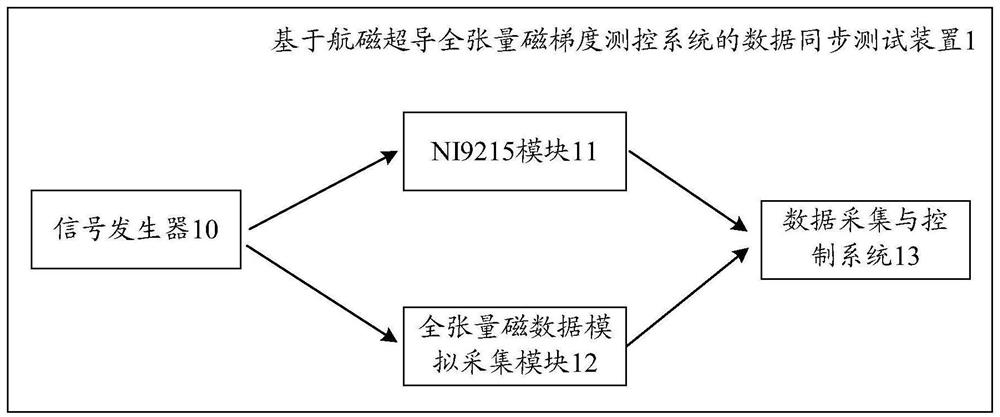

Data synchronization test device based on aeromagnetic superconducting full-tensor magnetic gradient measurement and control system

A measurement and control system and data synchronization technology, applied in the field of superconducting applications, can solve problems such as low synchronization accuracy, asynchronous full tensor magnetic data and position and attitude data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

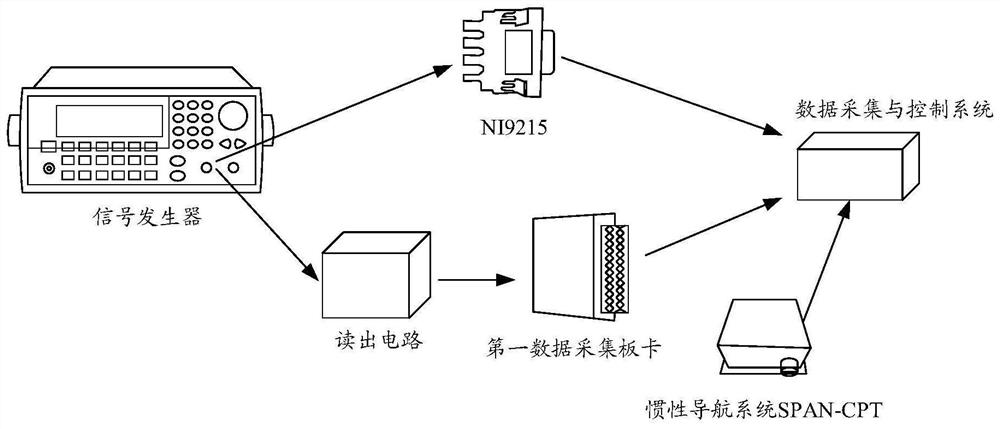

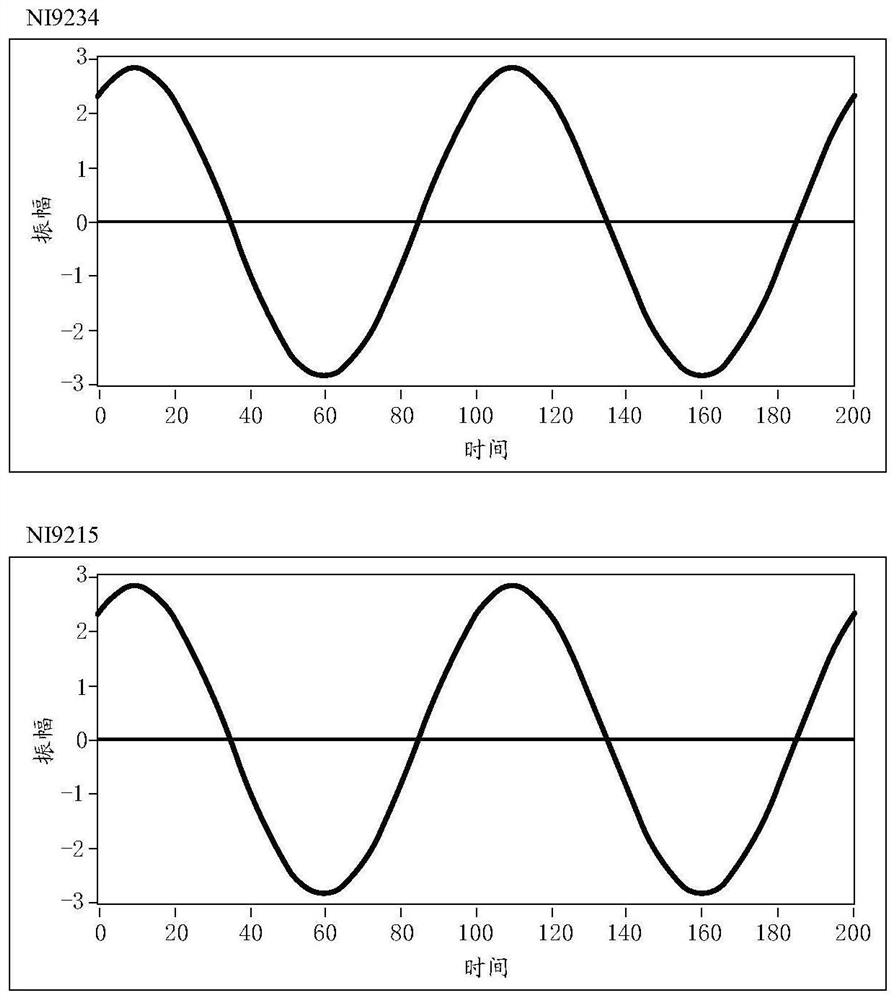

[0027] The aeronautical superconducting full-tensor magnetic gradient data acquisition and control system not only needs to collect full-tensor magnetic data, but also needs real-time position and attitude data corresponding to the full-tensor magnetic data, and the higher the synchronization, the better. The attitude data is used to effectively eliminate the interference introduced by the full tensor magnetic data in the moving state, and then the full tensor magnetic data after the interference is eliminated corresponds to the position information to obtain the spatial distribution information of the measured area. Therefore, the measurement accuracy of the position and attitude data and the synchronization with the full tensor magnetic data determine the data quality of the aeronautical superconducting full tensor magnetic gradient data acquisition and control system. The data sources are different, resulting in asynchronous full tensor magnetic data and position and attitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com