Container unloading stock bin device

A technology for containers and unloading bins, which is applied to measuring devices, loading/unloading, packaging, etc., can solve the problems of high physical exertion of workers, slow unloading speed, low work efficiency, etc., to ensure the safety of equipment and personnel, and prevent overloading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

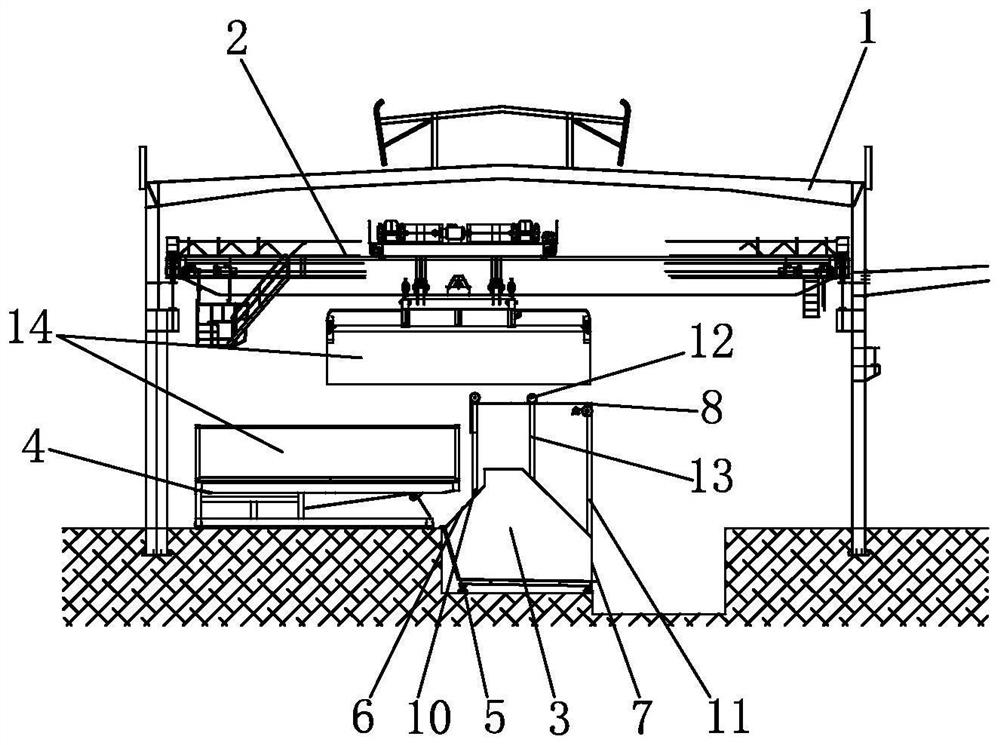

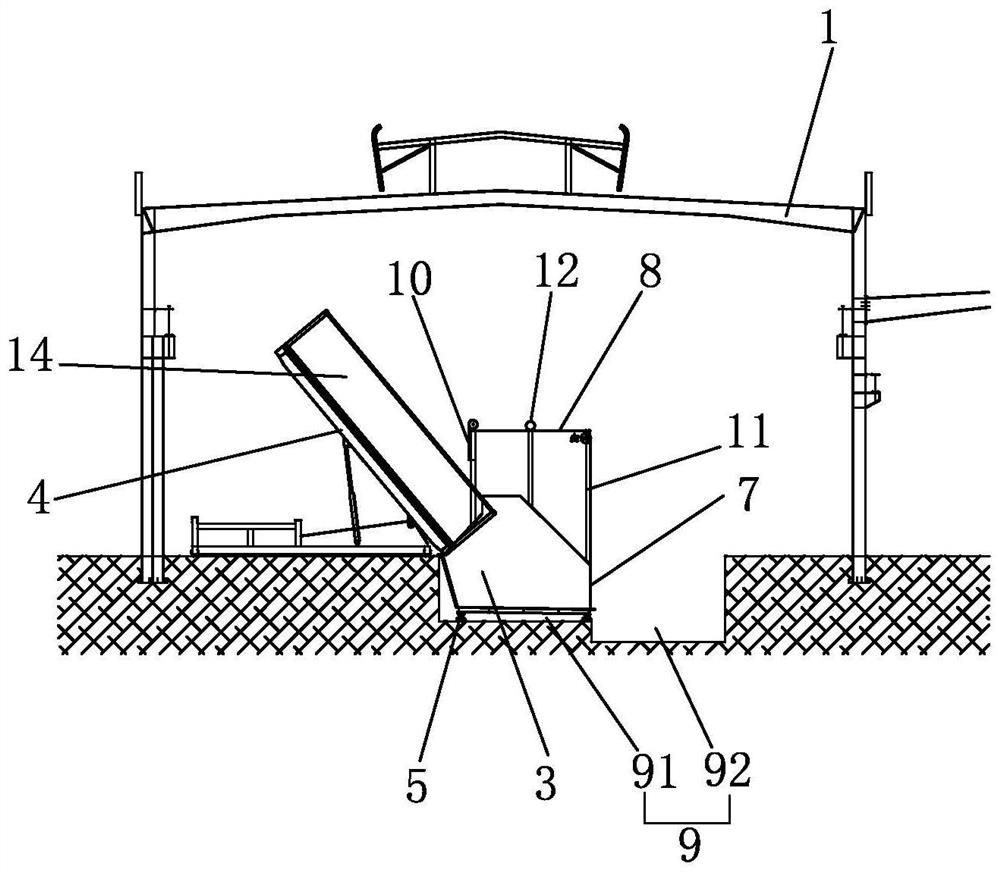

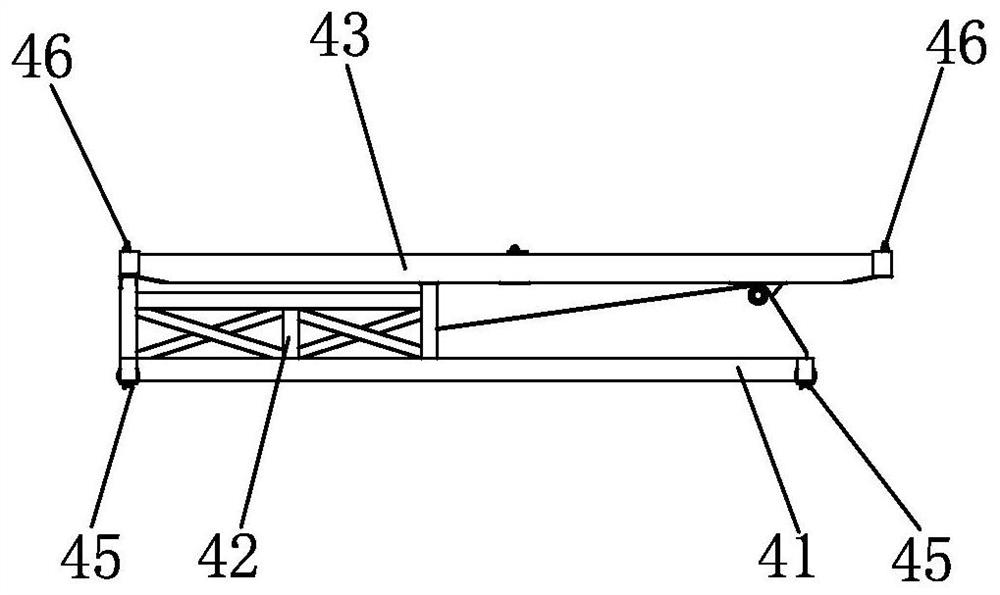

[0028] A container unloading bin device, such as Figure 1-5 As shown, it includes a row frame 1, a crane 2 arranged on the row frame 1 for lifting the container 14, a material bin 3 arranged below the row frame 1, and a turning machine 4 for turning over and unloading the container 14. The bottom of the silo 3 is provided with a silo weighing device 5, the front portion of the silo 3 is provided with an inlet 6, the rear portion of the silo 3 is provided with a discharge port 7, and the silo 3 is provided with a A dust collection cover 8, the front part of the dust collection cover 8 is provided with a front roll gate 10 that can close the feed opening 6, and the rear part of the dust collection cover 8 is provided with a rear roll gate that can close the discharge port 7 Gate 11. The silo 3 adopts a semi-closed design, and the container 14 runs to the 3 positions of the silo that need to be unloaded. The front rolling gate 10 of the silo 3 is opened, and the rear rolling ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com