A telescopic feeding machine weighing base

A feeding machine, retractable technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of no weighing function, easy to stop and go, complex structure, etc., to reduce the cost of replacement and update, and to facilitate installation and maintenance The effect of flexibility and convenient installation of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

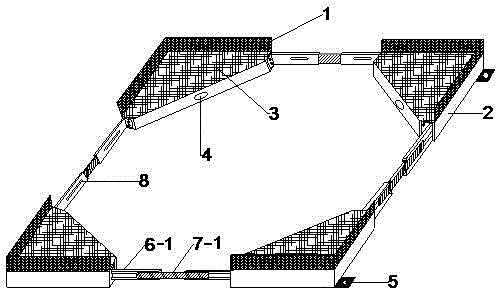

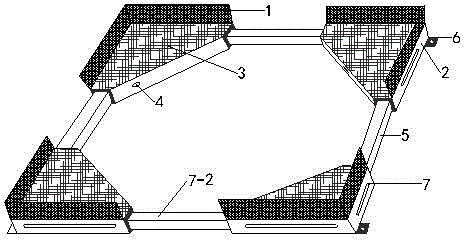

[0020] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 , figure 2 As shown, the weighing base of the retractable feeding machine shown in the present invention mainly includes four triangular boxes 2 of the same specification, and the storage platform 3 on the triangular box is independent, and it is convenient to be stressed when weighing; A baffle plate 1 with a certain height is provided to prevent the feeding machine from toppling over; each triangular box has an outlet 4 for a load cell; every two triangular boxes are connected by a telescopic slide rail or a slide bar; the telescopic slide rail consists of two An outer chute 6-1 and an inner slide block 7-1 form, and the telescopic slide bar is formed 7-2 by two mechanical chute 6-2 and a strip slide bar.

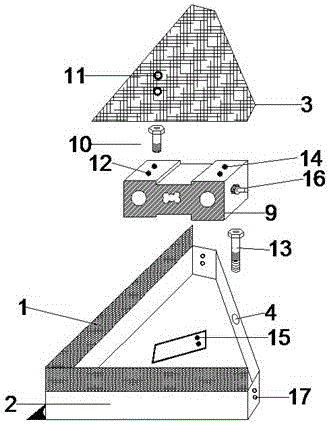

[0021] Before installing the base, you need to complete the assembly of the triangular box. The triangular box is as follows: image 3 , Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com