Multi-head combined scale overturning type funnel

A combined scale and flip-type technology, which is applied in the direction of conveyor control devices, conveyor objects, and emptying containers, can solve problems such as lowering work efficiency, inconvenient material receiving and feeding operations, and no flipping structure, etc., to improve work efficiency. Efficiency, convenient material receiving and feeding operations, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

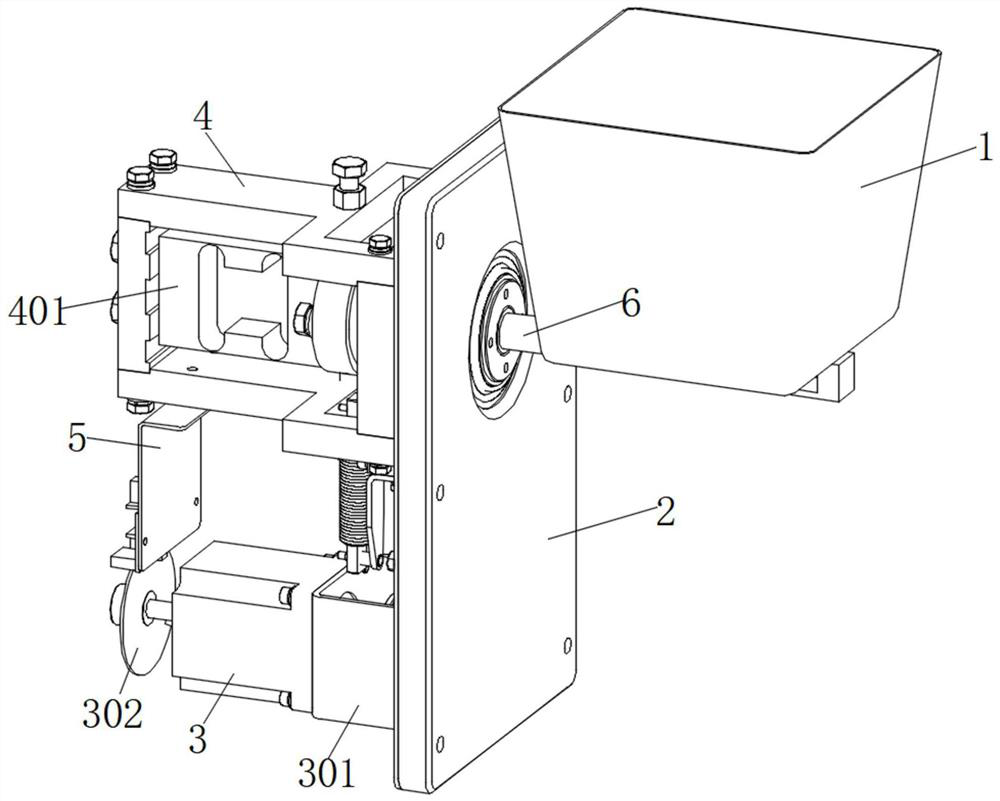

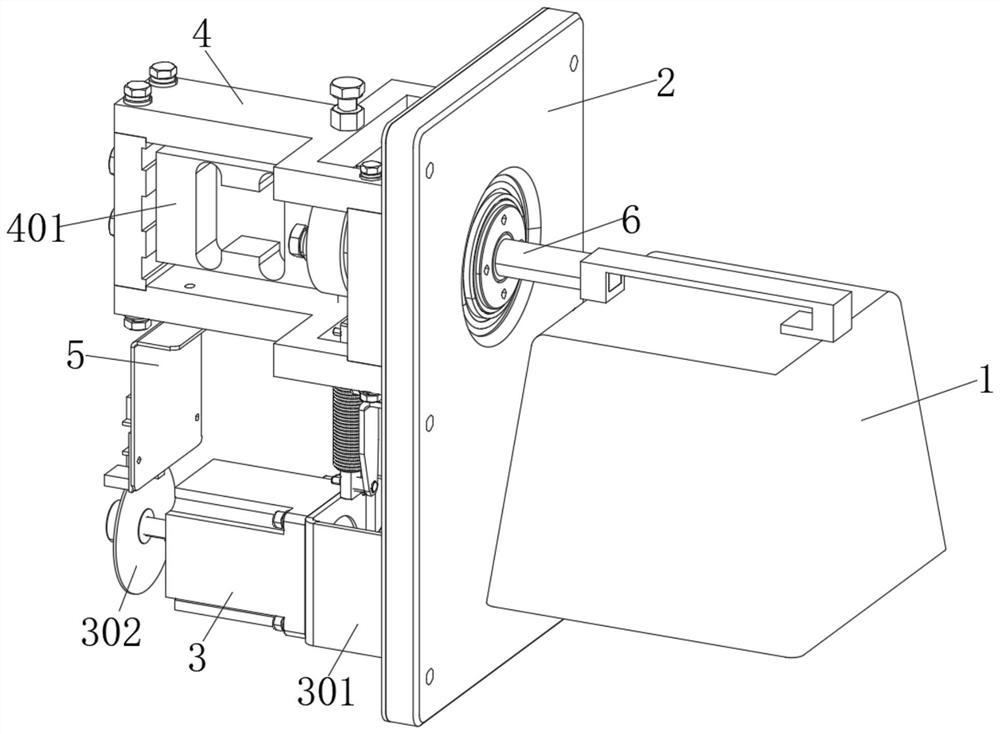

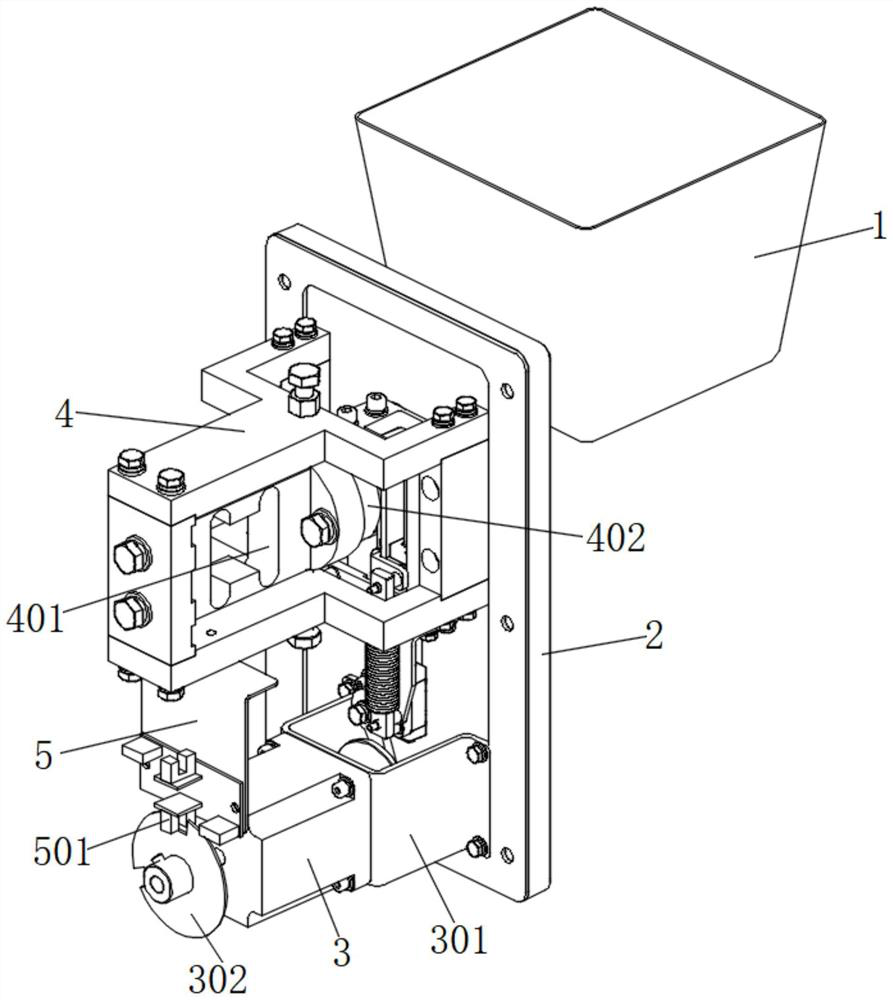

[0026] Such as Figure 1-6 As shown, a kind of multi-head combined scale flip-type funnel proposed by the present invention includes a hopper 1, a fixed plate 2 and a fixed frame 4, the rear end of the fixed plate 2 is fixedly installed with a fixed frame 4, and the inner side of the fixed frame 4 is fixedly installed with a Pedestal 402, the inside of pedestal 402 is installed with rotating shaft 6 extending out of fixed plate 2, the front end of rotating shaft 6 is fixedly equipped with receiving hopper 1, the outer side of pedestal 402 is fixedly installed with limit frame 9, the inside of limit frame 9 A movable frame 7 is slidably installed, and the inboard of the movable frame 7 is fixedly equipped with a tooth bar 701 cooperating with the transmission gear 601, and the rear end of the fixed plate 2 is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com