A laser measuring device for construction engineering and its measuring method

A technology of laser measurement and construction engineering, applied in active optical measurement devices, measurement devices, measurement instruments, etc., can solve the problems of affecting the accuracy of measurement, low stability, height inconvenience, etc., to avoid shaking and increase stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

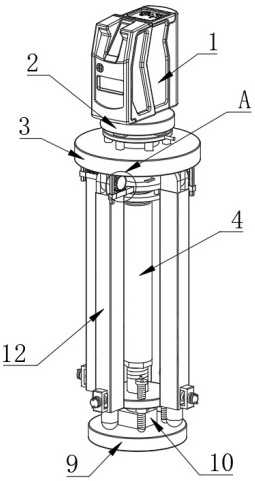

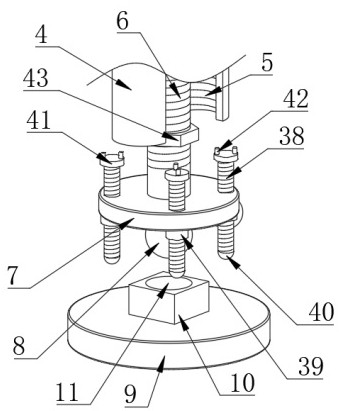

[0040] Example 1, please refer to Figure 1-Figure 9 , a laser measuring device for construction engineering includes a laser measuring equipment body 1, a rotating base 2 is fixedly connected to the bottom of the laser measuring equipment body 1, a fixing base 3 is arranged under the rotating base 2, and the rotating base 2 and the fixing base 3 are rotated The components are connected, the bottom of the fixed seat 3 is fixedly connected with the fixed column 4, the bottom of the fixed column 4 is provided with a threaded groove 5, and the threaded groove 5 is provided with a threaded column 6, and the bottom end of the threaded column 6 extends to the bottom of the fixed column 4, The outside of threaded column 6 is provided with nut 43, and nut 43 is in contact with fixed column 4, and the bottom of threaded column 6 is provided with base 9, and the top of base 9 is fixedly connected with first fixed block 10, and the top of first fixed block 10 A spherical groove 11 is pro...

Embodiment 2

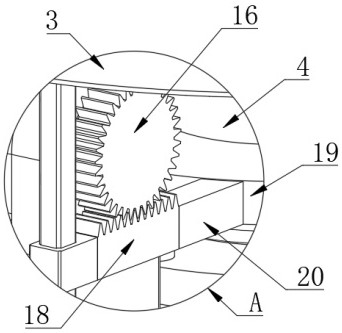

[0046] Embodiment two, on the basis of embodiment one, by figure 1 , Image 6 , Figure 7 and Figure 8 As shown, the lifting assembly includes two first rectangular holes 21 opened on the top of the movable ring 19 , and one inner wall of the first rectangular hole 21 communicates with the inner wall of the movable ring 19 .

[0047] A limiting bar 22 is arranged in the first rectangular hole 21 , and the limiting bar 22 is fixedly connected with the fixing column 4 .

[0048] A threaded ring 23 is sheathed on the outside of the fixed post 4 , and the threaded ring 23 is located below the movable ring 19 , and the fixed post 4 is provided with threads matching the threaded ring 23 .

[0049] The bottom of movable ring 19 is provided with annular groove 24, is provided with some slide blocks 25 in annular groove 24, and the bottom of slide block 25 is connected with the top of threaded ring 23 by second connecting column 26, and annular groove 24 and slide block The cross ...

Embodiment 3

[0053] Embodiment three, on the basis of embodiment one, by figure 1 , Figure 4 and Figure 5 As shown, the positioning assembly includes a second rectangular hole 29 opened on the inner wall of the first groove 13 , and a pressing plate 30 is disposed in the second rectangular hole 29 .

[0054] The rotating column 12 is fixedly connected with a support frame 31, one side of the support frame 31 is provided with a first threaded rod 32, one end of the first threaded rod 32 runs through the support frame 31, and one end of the first threaded rod 32 and the pressing plate 30 pass through the first A bearing 33 is connected.

[0055] The outside of the first threaded rod 32 is provided with a first threaded pipe 34, one side of the first threaded pipe 34 is fixedly connected to one side of the support frame 31, and one end of the first threaded rod 32 away from the first bearing 33 is fixedly connected with a fixed The plate 35, the pressing plate 30 is in contact with the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap