Wafer processing method

A processing method and wafer technology, which can be used in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., and can solve the problems of device chip quality degradation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

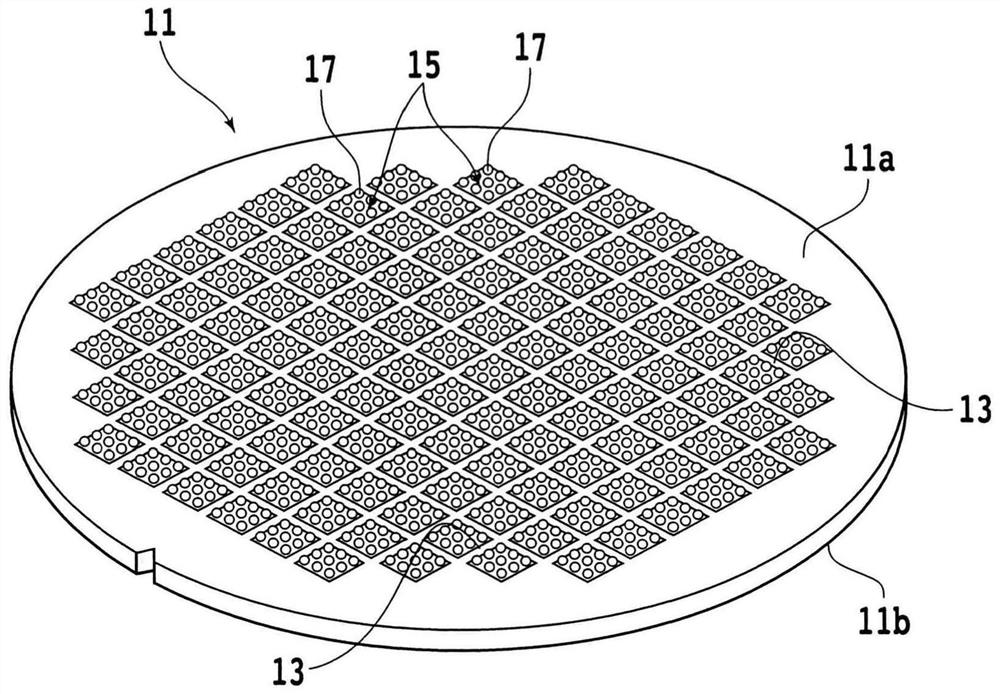

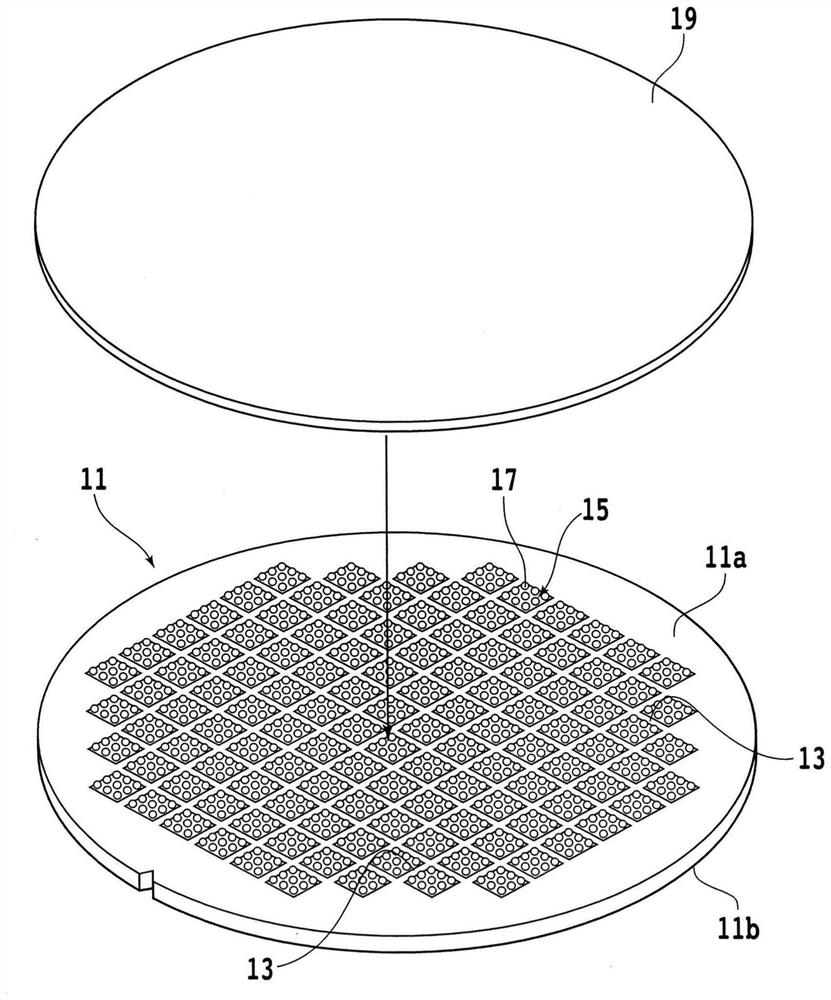

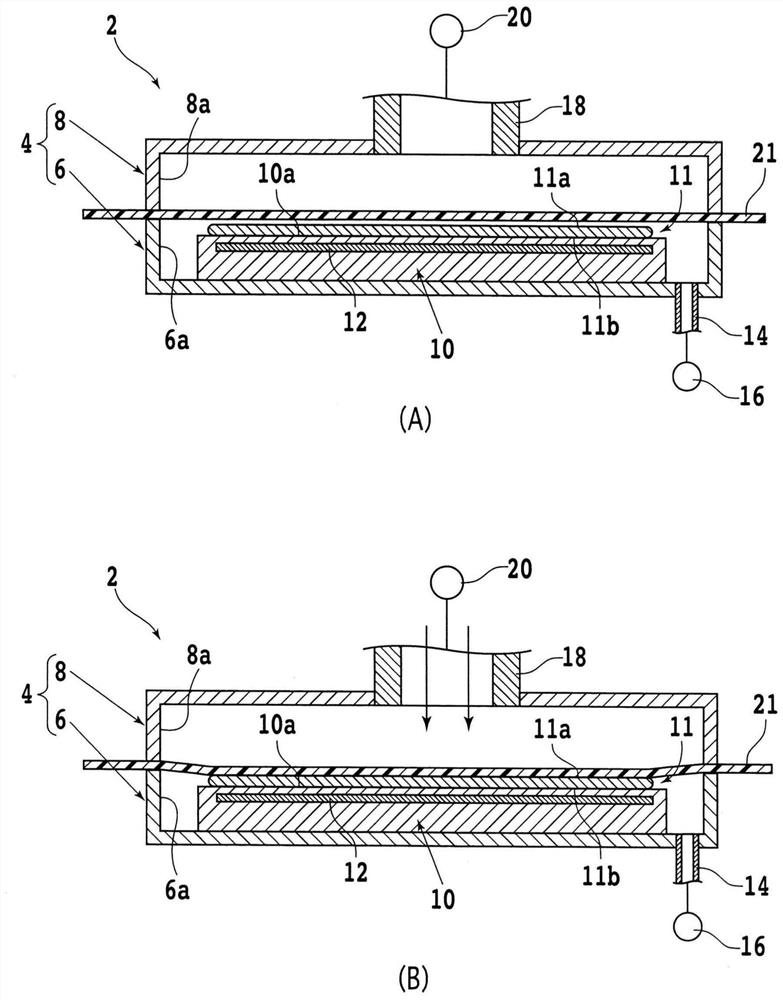

[0029] Hereinafter, an embodiment of one aspect of the present invention will be described with reference to the drawings. First, a configuration example of a wafer processed by the wafer processing method of this embodiment will be described. figure 1 is a perspective view showing the wafer 11 .

[0030] The wafer 11 is, for example, a disk-shaped substrate formed of a semiconductor such as silicon, and has a front surface (first surface) 11a and a rear surface (second surface) 11b substantially parallel to each other. The wafer 11 is divided into a plurality of rectangular regions by a plurality of dividing lines (streets) 13 arranged in a grid pattern so as to intersect each other. In addition, IC (Integrated Circuit, integrated circuit), LSI (Large Scale Integration, large-scale integration), LED (Light Emitting Diode, light emitting diode), MEMS (Micro Electro Mechanical Systems, Micro Electro Mechanical Systems) and other devices 15 .

[0031] In addition, the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com