Drainage wire fixing device

A technology of fixing device and drainage wire, applied in the direction of cable suspension device, etc., can solve the problems of inconvenient operation, time-consuming and labor-intensive, etc., and achieve the effect of convenient and fast fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

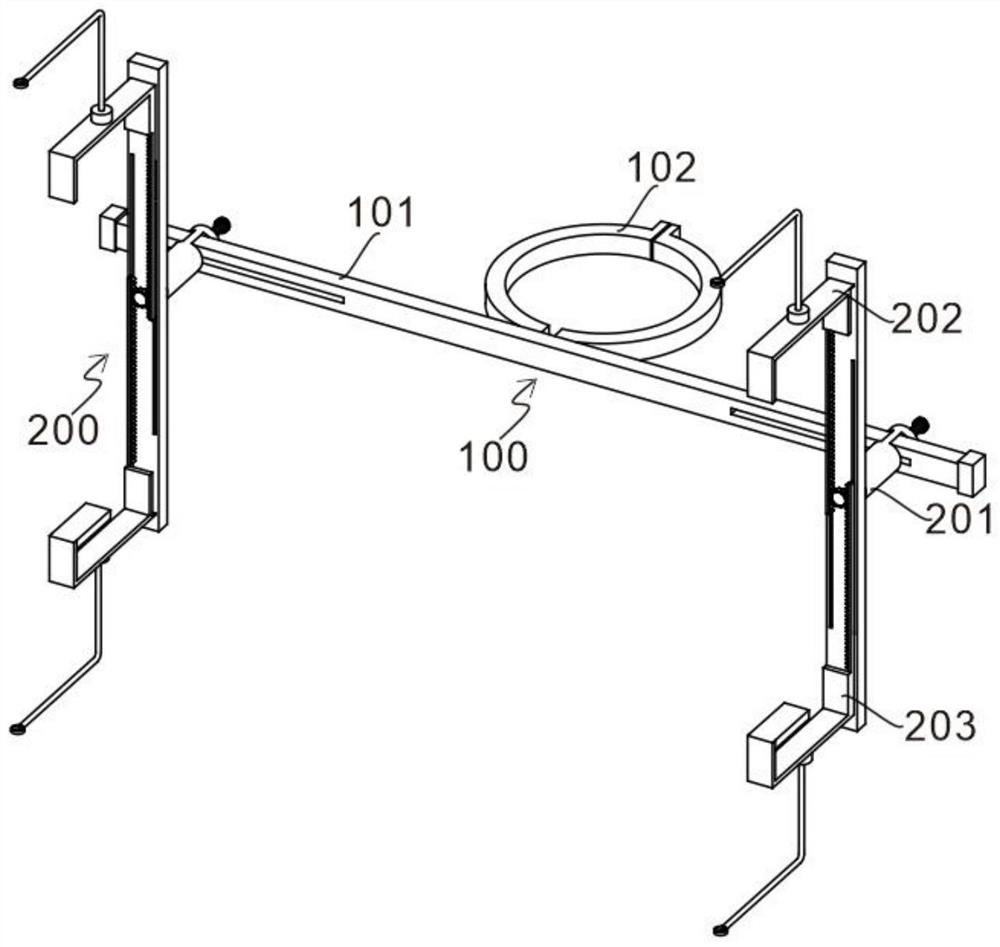

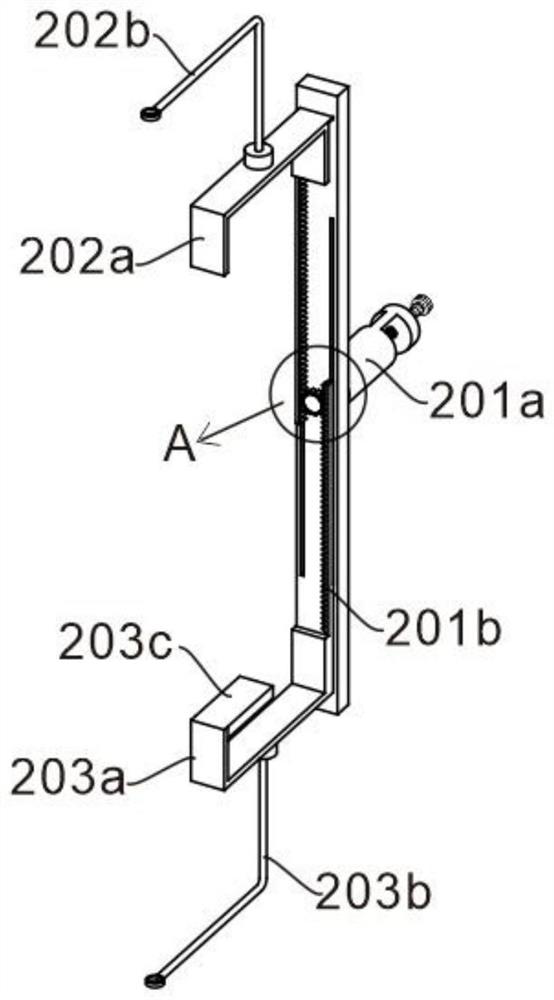

[0027] refer to figure 1 , is the first embodiment of the present invention, which provides a drain wire fixing device, which includes a pole fixing assembly 100, including a connecting rod 101 and a movable hoop 102, and the movable hoop 102 is arranged on the connecting rod 101 At the middle position, the pole fixing assembly 100 is used to fix the device on the outside of the pole; the cross arm fixing assembly 200, the cross arm fixing assembly 200 is used to fix the bypass device on the cross arm, including the displacement fixing part 201, the upper connection 202 and the lower connecting piece 203, the displacement fixing piece 201 is arranged at the end of the connecting rod 101, the displacement fixing piece 201 is used to adjust the fixed position of the device on the cross arm, and the upper connecting piece 202 and the lower connecting piece 203 are respectively set at the displacement The upper and lower ends of the fixing part 201, the upper connecting part 202 a...

Embodiment 2

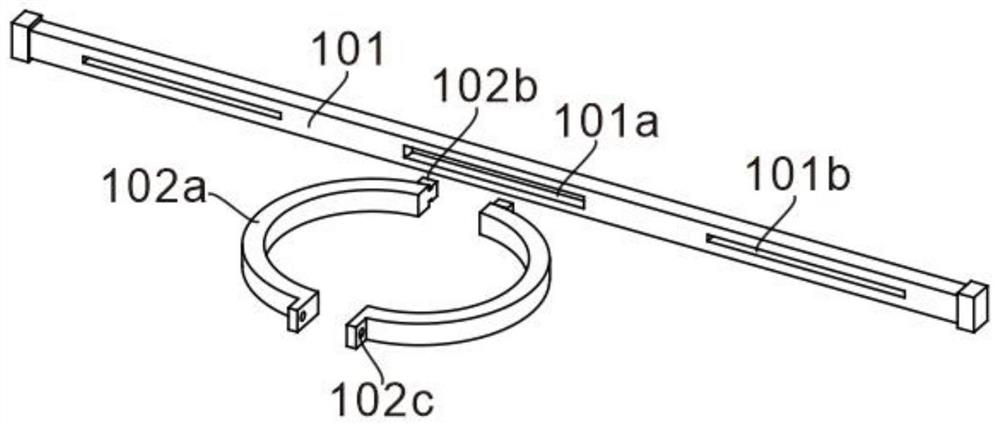

[0031] refer to Figure 1 to Figure 7 , is the second embodiment of the present invention, and it is different from the first embodiment in that: a first sliding groove 101a is provided at the middle position of the connecting rod 101, and the movable hoop 102 includes two groups of semicircular hoops 102a, the semicircular hoops 102a is disposed in the first sliding slot 101a through the slider 102b. A bolt connection hole 102c is provided at the end of the semicircular hoop 102a away from the slider 102b.

[0032] Two sets of semi-circular hoops 102a realize cohesion and fixation of electric poles of any diameter. By moving the slider 102b located in the first chute 101a, the cohesion diameter of the semi-circular hoops 102a can be changed to adapt to poles of different diameters. Through the semi-circular hoops The bolt connection holes 102c provided on the strips 102a fix the two sets of semicircular hoops 102a together and hold the pole tightly, so that the whole device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com