Column-type porcelain insulator wire self-locking device

A technology of self-locking device and wire, which is applied in the direction of cable suspension device and cable space arrangement/configuration, etc., which can solve the problems of easy wire burnout, insulation layer damage and discharge, etc. effect of breaking and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

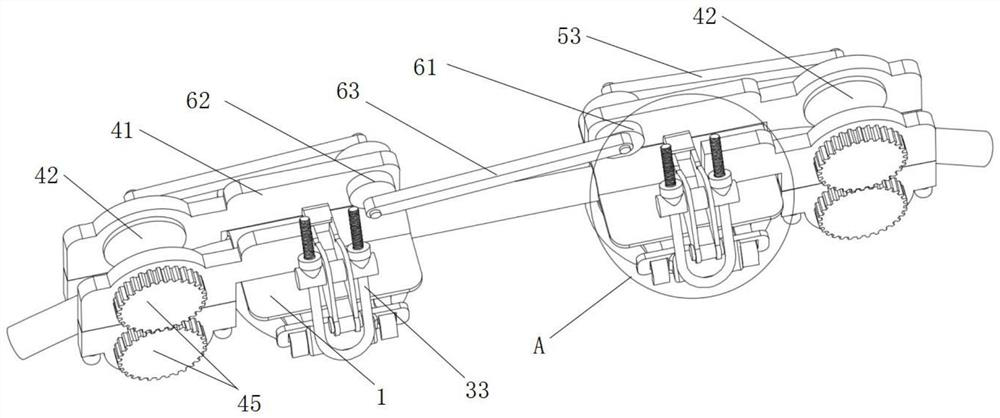

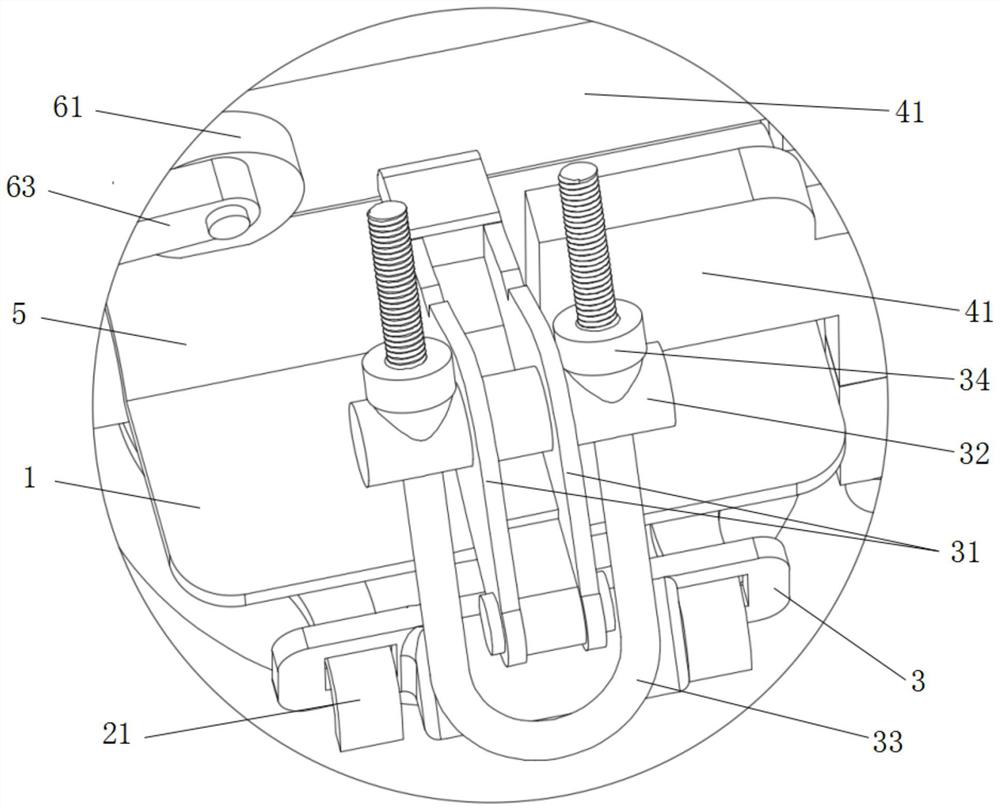

[0026] like Figure 1 to Figure 8 As shown, the present invention provides a self-locking device for the wire of a column type porcelain bottle, including a pressing plate 1, a buckle 2, a buckle mechanism, a guide limit mechanism and a linkage mechanism, wherein one side of the buckle 2 is hinged to the side of the pressing plate 1 One side, so that the buckle 2 can rotate around one end of the pressure plate 1; the buckle mechanism is hinged on the pressure plate 1, so that the buckle mechanism can adjust the fastening angle; the buckle 2 is buckled into the upper end of the column type porcelain bottle 6 by horizontal extrusion, The buckle mechanism is provided with a clamping part 3 that is socketed and clamped with the bending parts 21 at both ends of the opening of the buckle ring 2, so that the bending part 21 is buckled into the rectangular through holes on both sides of the clamping part 3; the guide limit The mechanism is set on the pressure plate 1 to roll and compr...

Embodiment 2

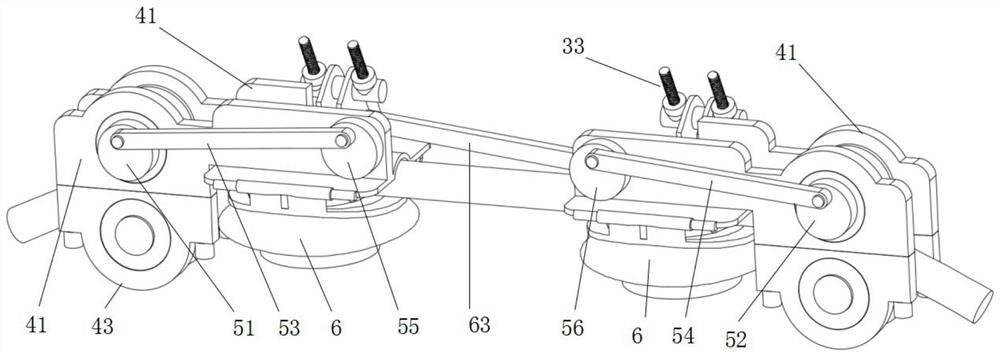

[0032] like Figure 1 to Figure 6As shown, in combination with the technical solution of Embodiment 1, in this embodiment, the linkage mechanism includes a first turn block 51, a second turn block 52, a first push rod 53, a second push rod 54, a first round block 55, a second turn block Two circular blocks 56 and synchronous reverse rotation device, the first rotary block 51 is coaxially connected with one upper pressing wheel 42, the second rotating block 52 is coaxially connected with another upper pressing wheel 42, the first circular block 55 and The second round block 56 is rotatably arranged on the upper support frame 41; the two ends of the first push rod 53 are respectively hinged on the first rotary block 51 and the first round block 55, and the two ends of the second push rod 54 are respectively hinged on the first round block 55. On the second turning block 52 and the second round block 56; the synchronous reverse rotation device is connected with the first round bl...

Embodiment 3

[0035] like Figure 7 to Figure 8 As shown, the difference between this embodiment and Embodiment 2 is that the reverse rotation device includes a first ring gear 71, a second ring gear 72, an upper rack 73 and a lower rack 74, and the first ring gear 71 is fixedly connected to the second ring gear. On the outer ring of a rotary block 51, the second ring gear 72 is fixedly connected to the outer ring of the second rotary block 52, the upper rack 73 is meshed with the vertical upper end of the first ring gear 71, and the lower rack 74 is connected to the second ring gear 71. The vertical lower end of the ring gear 72 is engaged and connected, and one end of the upper rack 73 and one end of the lower rack 74 are connected by a vertical bar 75 to drive the first ring gear 71 or the second rotating block 52 when the first rotating block 51 rotates. When rotating, the second ring gear 72 is driven to rotate, so that the upper rack 73 and the lower rack 74 push the first ring gear 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com