Stranding and combining all-in-one machine for producing 7*7 structural steel wire rope

An all-in-one machine and section steel technology, which is applied in the field of steel wire rope production devices and strand-twisting and rope-bonding integrated machines, can solve the problems that the wire cannot be bent back and forth repeatedly, the steel wire rope is not as flexible as the fiber rope, and the lay length is inconsistent, so as to save time and improve Efficiency, the effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

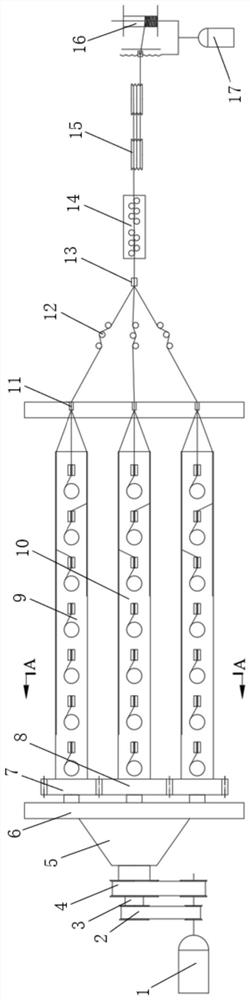

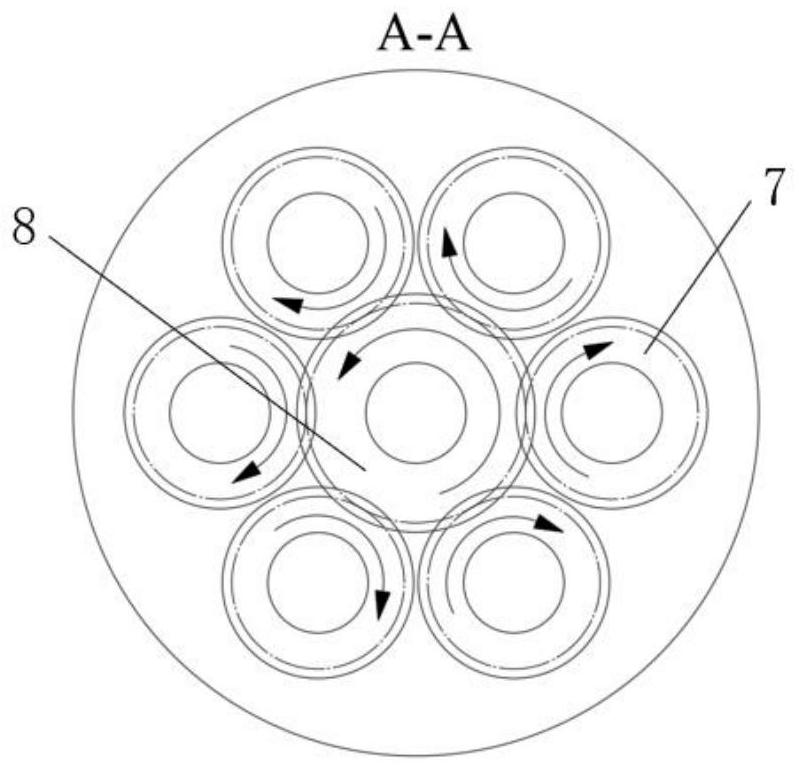

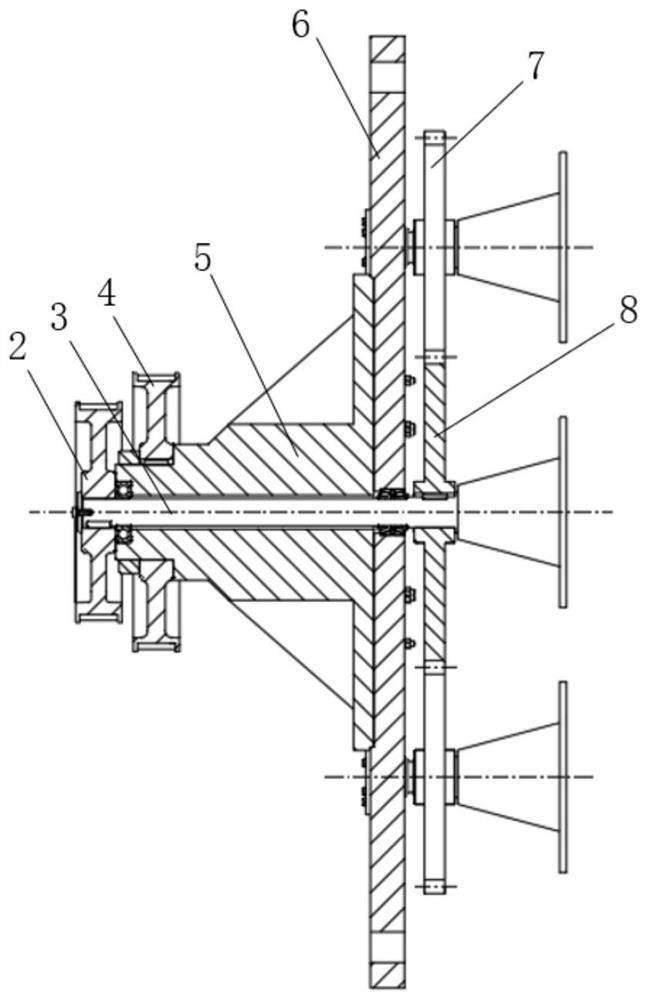

[0053] like Figure 1-3 As shown, the present invention combines the working characteristics of the tubular stranding machine and the basket type closing machine, and proposes an overall design scheme of an integrated twisting and closing machine for producing 7×7 structural steel wire ropes. The scheme is to combine the two into one on the basis of the tubular stranding machine and the basket type closing machine, and to develop the tubular stranding machine into a twisting tube, and to develop the basket type closing machine into a public The rotation of the turntable and the strand tube drives the seven steel wires on it to twist strands, and the revolution of the revolving disc drives the revolution of the seven strand tubes on it to rotate and close the rope, thereby producing a 7×7 structural steel wire rope and realizing the integration of stranding and rope closing in steel wire rope production.

[0054] This scheme mainly includes three movements, the rotation and rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com