Aircraft air inlet test device and system and hot air anti-icing test stability judgment method

The technology of a test device and test system, which is applied in the field of wind tunnel test, can solve the problems of low anti-icing efficiency and waste of hot air entrained air resources, etc., and achieve the effect of improving anti-icing efficiency and saving hot air entrained air resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

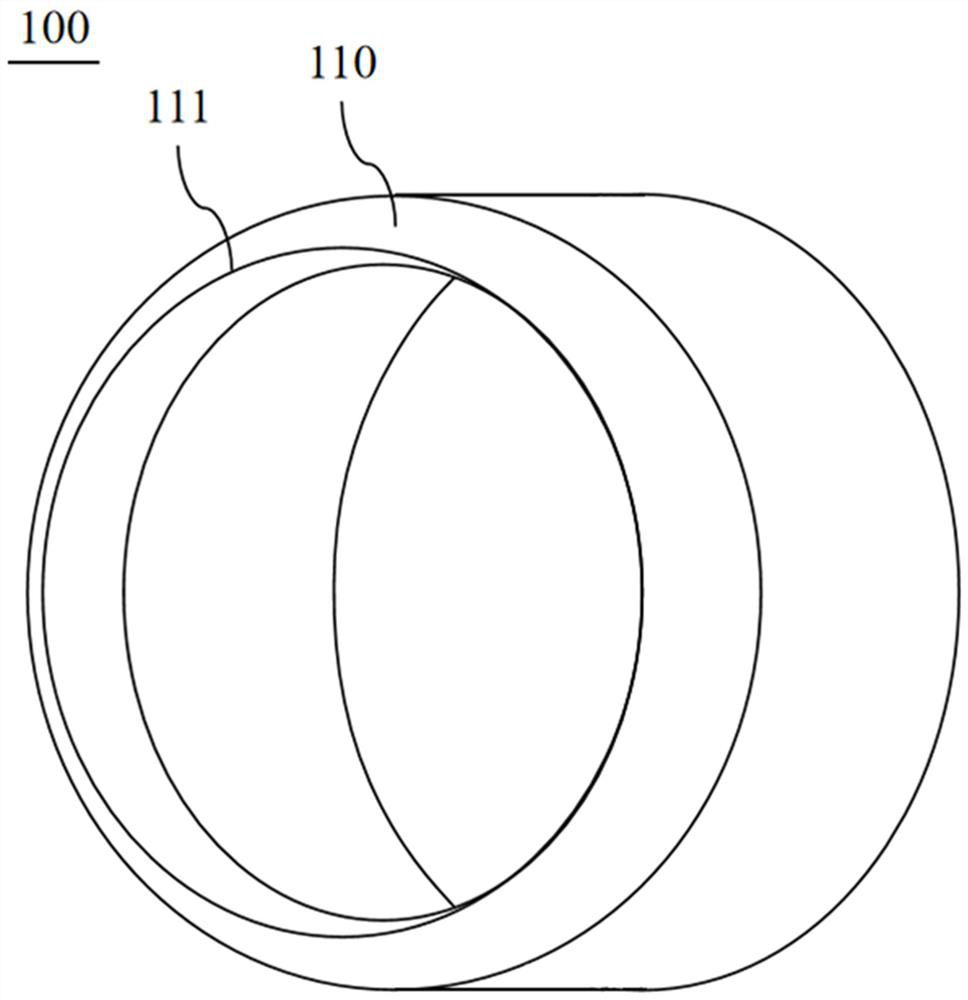

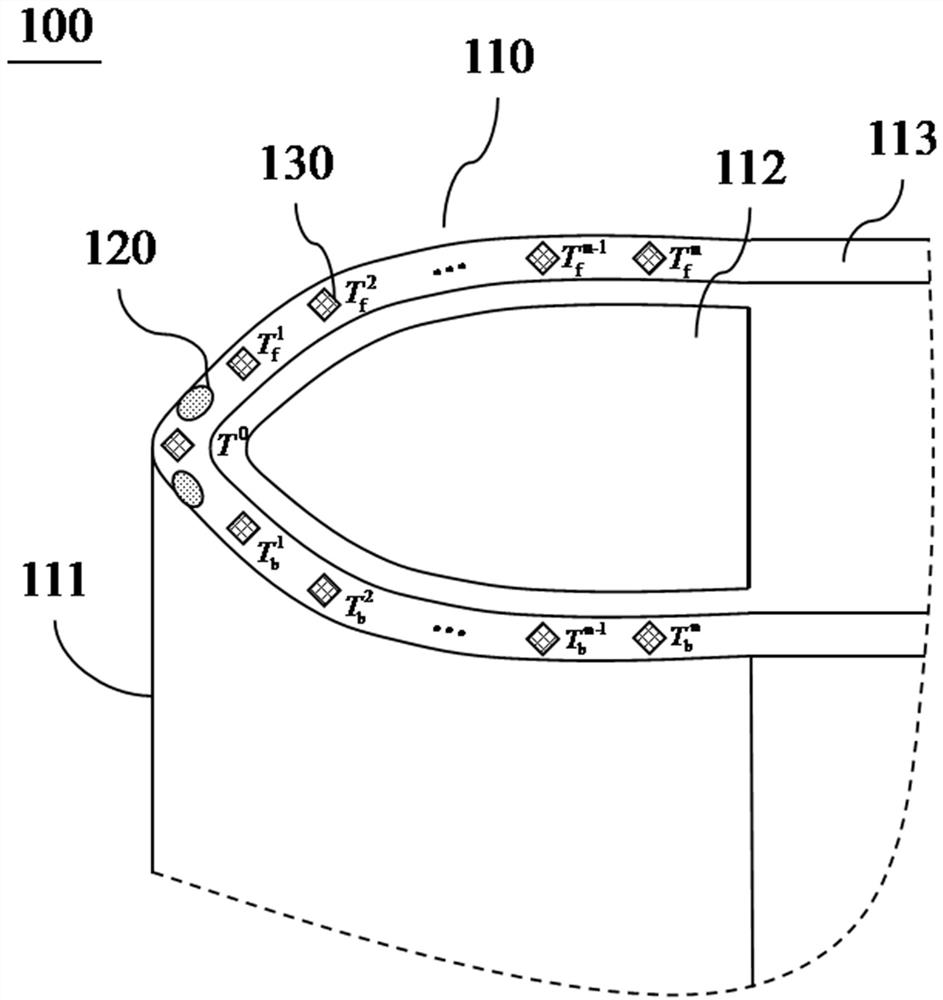

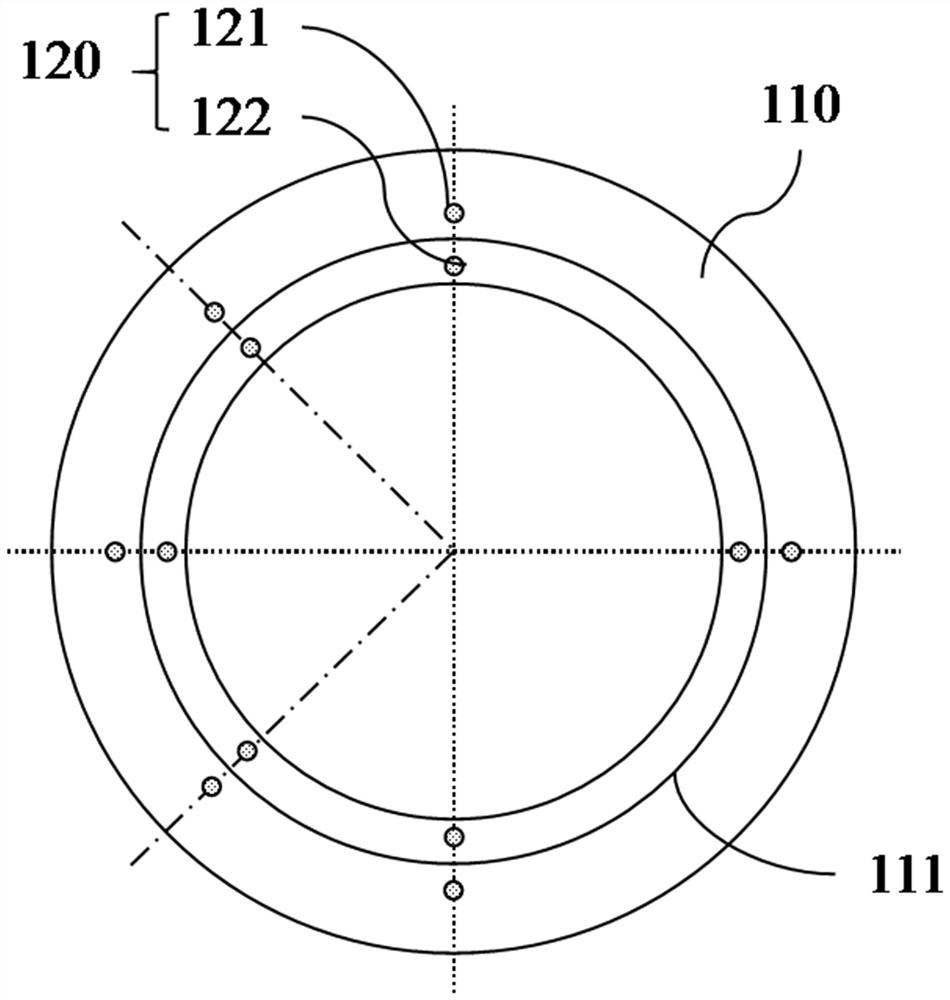

[0037] Such as figure 1 As shown, the embodiment of the present invention provides a aircraft intake diameter test device 100, and a lip 110 is provided with a thermal gas chamber 112 inside the lip 110, the lip 110. A plurality of monitoring structures are provided along the side wall of 110 in the leading edge 111 extending, the monitoring structure including the temperature measuring assembly 130 and the icing measurement assembly 120, the temperature measuring assembly 130 and the knot ice measurement assembly 120 located before On the same section of the edge 111, the temperature measuring assembly 130 is used to acquire the temperature of the outer surface of the lip 110, which is used to acquire frozen information of the outer surface of the lip 110.

[0038]The Applicant has undergone long-term practical experience: the design of reasonable air intake is a key point of hot air, which is to protect the part from joining interference while ensuring stable operation of the en...

Embodiment 2

[0054] Such as Figure 4 As shown, the second embodiment of the present invention provides a aircraft intake diameter test system, including a control module and a data monitoring module connected to each other, the data monitoring module including the aircraft intake diameter test device 100, the data. The monitoring module is connected to the monitoring structure.

[0055] The control module is configured to adjust and control the hot gas parameters supplied to the thermal cavity 112 in the lip 110 in accordance with the data monitoring module; the data monitoring module is used to obtain data monitored in the monitoring structure, including at least temperature data and Icing information.

[0056] Further, the monitoring structure includes a temperature measurement assembly 130 and a frozen measurement assembly 120, the data monitoring module being coupled to the temperature measuring assembly 130 and the icing measurement assembly 120.

Embodiment 3

[0058] Such as Figure 5 As shown, the third embodiment of the present invention provides a thermal anti-ice test determ, including the steps of:

[0059] Step S10: Open the aircraft into the airway test system;

[0060] Step S20: Controlling the hot air parameters until the temperature difference value of the preset temperature measurement is less than the preset temperature difference value, and the icing measurement assembly 120 does not monitor frozen information in the preset time period, Then determine the test conditions stabilization; the preset measuring temperature of the preset measuring point includes a medium temperature temperature point, at least partially measured temperature points and at least partially subtracted temperature points.

[0061] Such as figure 2 As shown, the temperature measurement assembly 130 includes a medium temperature temperature point according to the cross-sectional position of the lip 110. T 0 Upper test temperature T f And lower test tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com