GIS room equipment in-and-out dustproof transition room and using method thereof

A kind of equipment and dust-proof technology, which is applied in the setting of switchgear, switchgear, electrical components, etc., can solve the problems such as the cleanliness of the construction site not meeting the requirements, so as to improve the cleanliness not up to standard, save manpower, and be simple and economical benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] The present invention provides a kind of technical scheme: using steps include as follows:

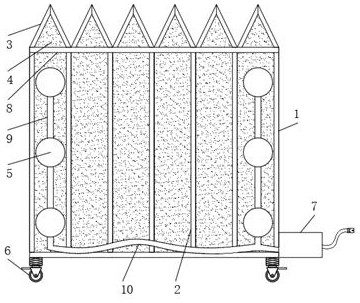

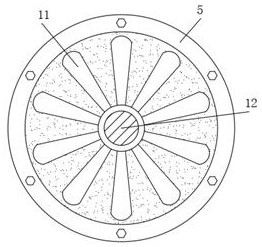

[0040] S1, preparation materials: prepare galvanized square pipe 2, ceiling support rod 3, waterproof shed cloth 4, dust removal purifier 5, universal wheel 6, battery power supply device 7, horizontal pipe 8, connecting pipe 9 and hose 10, etc. s material;

[0041] S2, installation and fixing: the waterproof shed cloth 4 is directly bolted and fixed on the outside of the transition room body 1 through ropes, and the galvanized square tube 2 and the horizontal tube 8 support the transition room body 1 as a whole;

[0042] S3, storage and support: sliding and telescopic storage or support of the ceiling support rod 3 through the movable shaft 13 and slide rail 14 on the top;

[0043] S4, power supply and dust removal: the dust removal purifier 5 and the connecting pipe 9 are fixedly installed on the outer ends of both sides of the transition room body 1, and the bottom of the du...

example 2

[0046]The present invention provides a kind of technical proposal: using step comprises as follows:

[0047] S1, preparation materials: prepare galvanized square pipe 2, ceiling support rod 3, waterproof shed cloth 4, dust removal purifier 5, universal wheel 6, battery power supply device 7, horizontal pipe 8, connecting pipe 9 and hose 10, etc. s material;

[0048] S2, installation and fixing: the waterproof shed cloth 4 is directly bolted and fixed on the outside of the transition room body 1 through ropes, and the galvanized square tube 2 and the horizontal tube 8 support the transition room body 1 as a whole;

[0049] S3, storage and support: sliding and telescopic storage or support of the ceiling support rod 3 through the movable shaft 13 and slide rail 14 on the top;

[0050] S4, power supply and dust removal: the dust removal purifier 5 and the connecting pipe 9 are fixedly installed on the outer ends of both sides of the transition room body 1, and the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com