Brushless motor and rotor thereof

A brushless motor and rotor technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of back EMF difference, high manufacturing cost, inability to meet FOC drive requirements, etc., to improve electromagnetic noise, reduce motor costs, The effect of improving motor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

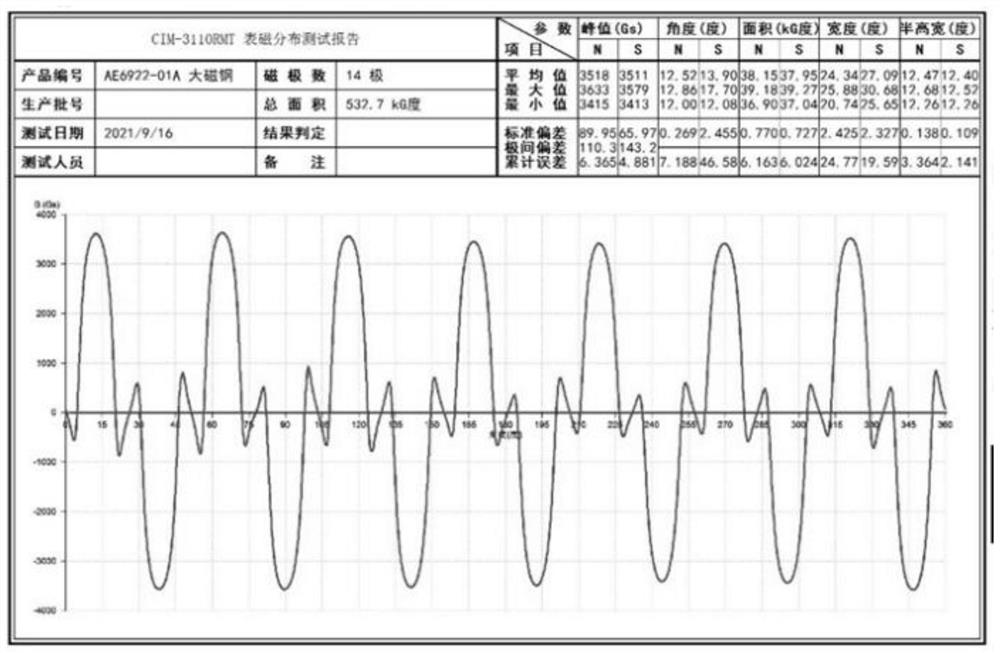

[0039] Figure 4 Some preferred embodiments of the brushless motor of the present invention are shown. The brushless motor has the advantages of low noise, good performance and light weight.

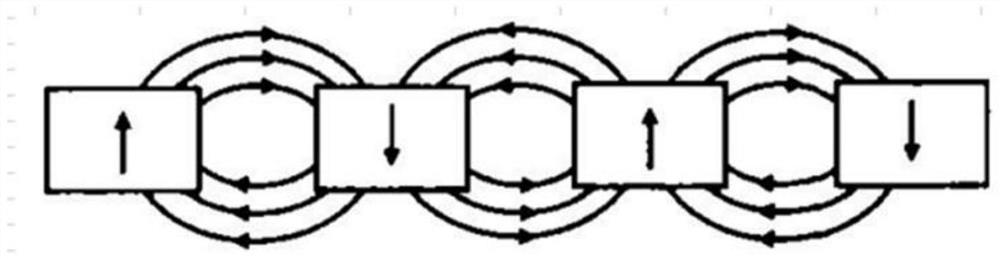

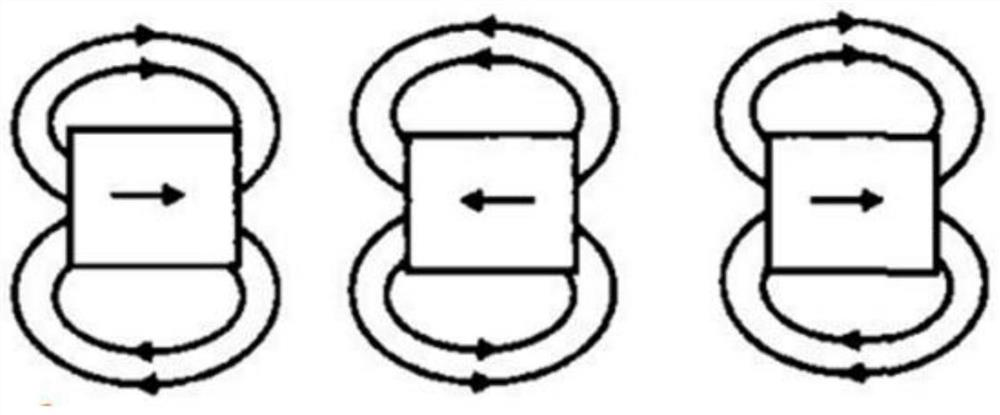

[0040] Such as Figure 4 As shown, in some embodiments, the brushless motor may include a rotor and a stator assembled with the rotor. The rotor may include a rotor core 10 , a first magnet 20 , and a second magnet 30 . The rotor core 10 can be cylindrical, and there are multiple first magnets 20, and the multiple first magnets 20 can be arranged at intervals along the circumference of the rotor core 10, and each first magnet 20 can be A first magnetic field is generated in the radial direction of the rotor core 10 . The seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com