Container transportation loading and unloading system and method

A loading and unloading system and container technology, which is applied in the directions of transportation and packaging, loading/unloading, packaging, etc., can solve the problems of special lifting equipment coordination and transfer flow difficulties, cargo damage and leakage, and transfer flow difficulties, so as to save money and interest The effect of cost, less damage and leakage of goods, and reduction of storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

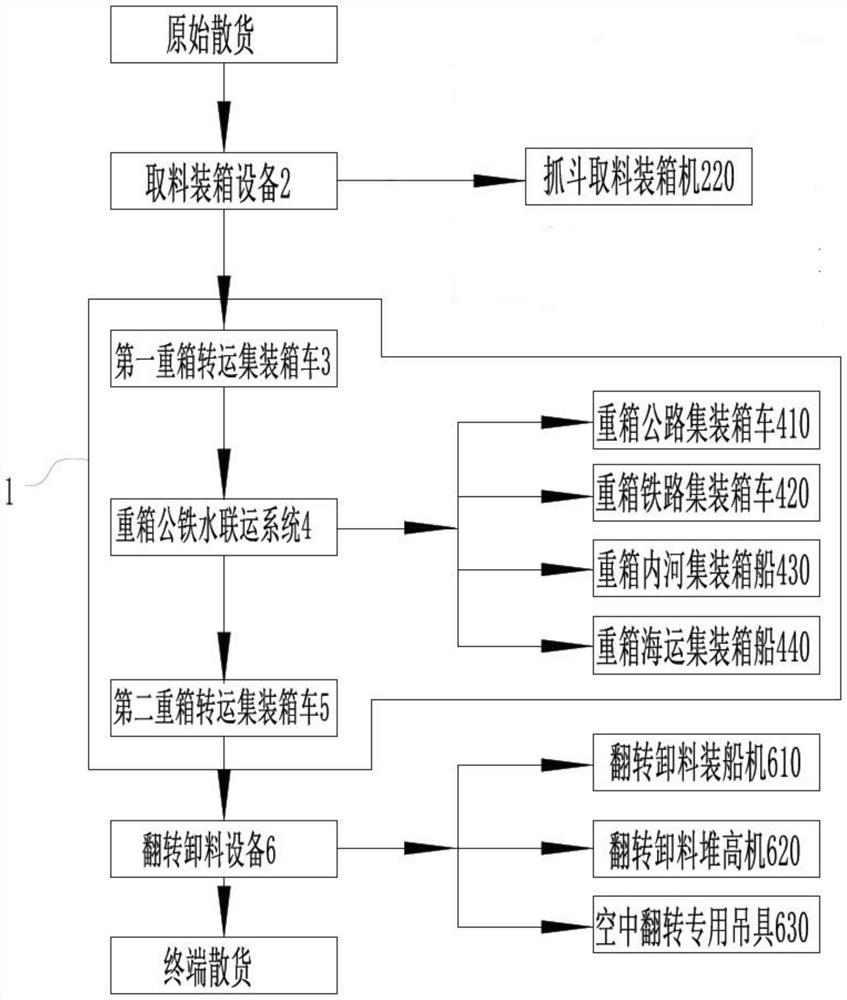

[0132] Such as figure 1 As shown, a kind of container transport handling system described in this embodiment includes:

[0133] Retrieving and packing equipment 2, which is located at the place where the material is sent out, and retrieving and transporting the original material to an empty container for container packing;

[0134] Container transfer system 1, which transfers the heavy container filled with materials to the material unloading place with turning unloading equipment;

[0135] Turn over unloading equipment 6, which is located at the material unloading place, and unloads the material in the heavy container that has been transferred.

[0136] In this embodiment, the container transfer system 1 includes a first heavy container transfer container truck 3, a second heavy container transfer container truck 5, and a heavy container rail-water combined transport system 4, and the first heavy container transfer container truck 3 is located at the reclaiming and packing e...

Embodiment 2

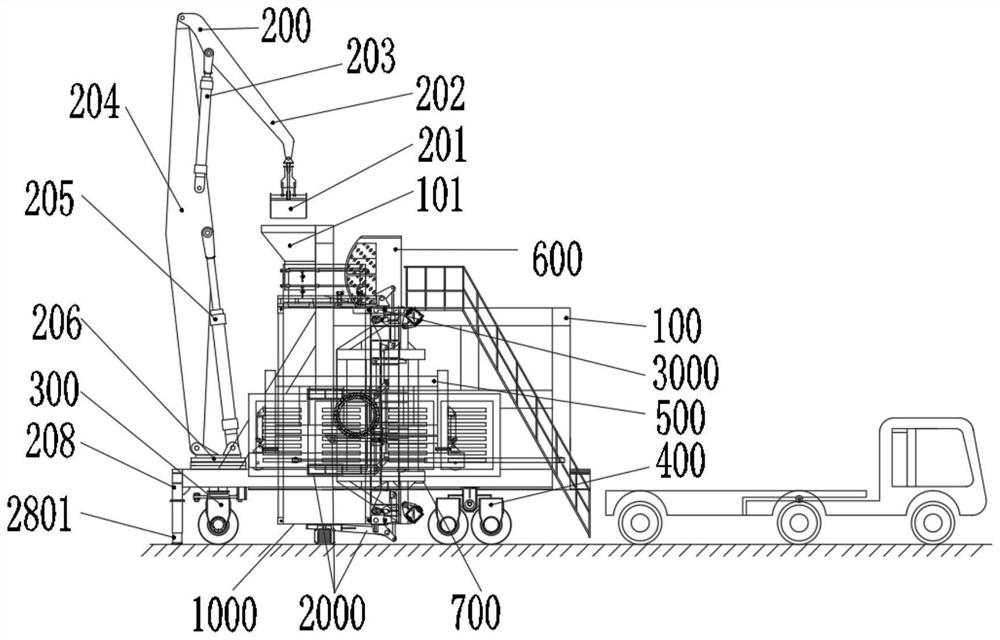

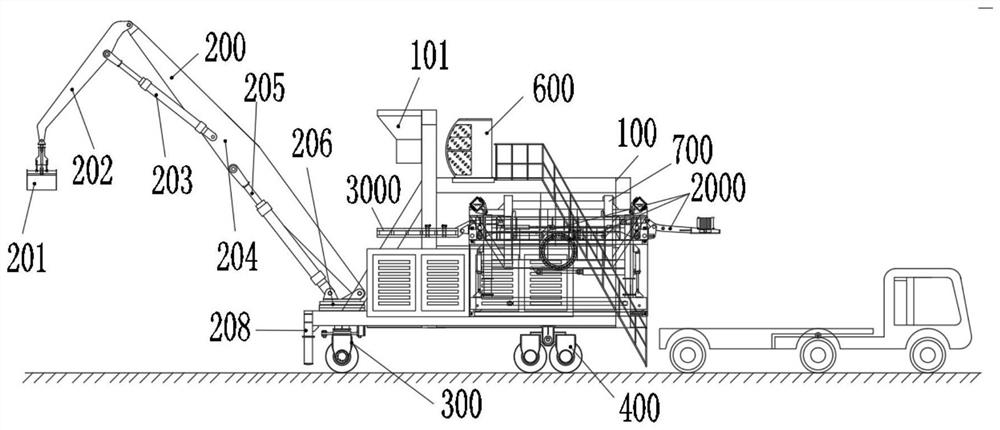

[0143] The general structure of the container transportation and handling system described in this embodiment is consistent with that of Embodiment 1, but it is different from Embodiment 1 in that the grab bucket loading and unloading machine includes a loading frame 100 for carrying containers, a grab The bucket retrieving mechanism 201, and the movable arm installed on the feeding frame, the feeding guide funnel, the packing turning mechanism and the translation drive mechanism, the movable arm includes the stick 202, the stick cylinder 203, the boom 204, and the boom cylinder 205 and the second rotary mechanism 206, the second rotary mechanism 206 is installed on the loading frame 100, the grab bucket reclaiming mechanism 201 is connected with one end of the arm 202, and the other end of the arm 202 is rotatably connected with one end of the boom 204 , the other end of the boom 204 and the cylinder end of the boom cylinder 205 are rotatably connected to the second slewing me...

Embodiment 3

[0181] The general structure of the container transport handling system described in this embodiment is consistent with that of Embodiment 1, but it is different from Embodiment 1 in that: the turning and unloading equipment includes a turning and unloading ship loader, and the turning and unloading ship loader includes Unloading frame 7100, unloading conveying mechanism 7200, lifting drive mechanism 7900 and unloading funnel 7700, unloading funnel 7700 is arranged at the bottom of unloading channel of unloading frame 7100, the bottom of unloading conveying mechanism 7200 and unloading frame 7100 Rotary connection; the lifting drive mechanism 7900 is fixed on the unloading frame 7100, the lifting drive part is connected with the unloading conveying mechanism 7200, and the bottom end of the unloading conveying mechanism 7200 is docked with the discharge port of the unloading funnel 7700; the unloading frame The unloading channel of 7100 is equipped with a discharge turning mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com