Basement civil air defense structure and construction method

A basement and civil air defense technology, which is applied to building components, war damage prevention, building construction, etc., can solve the problem of low efficiency of opening and closing explosion-proof doors, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

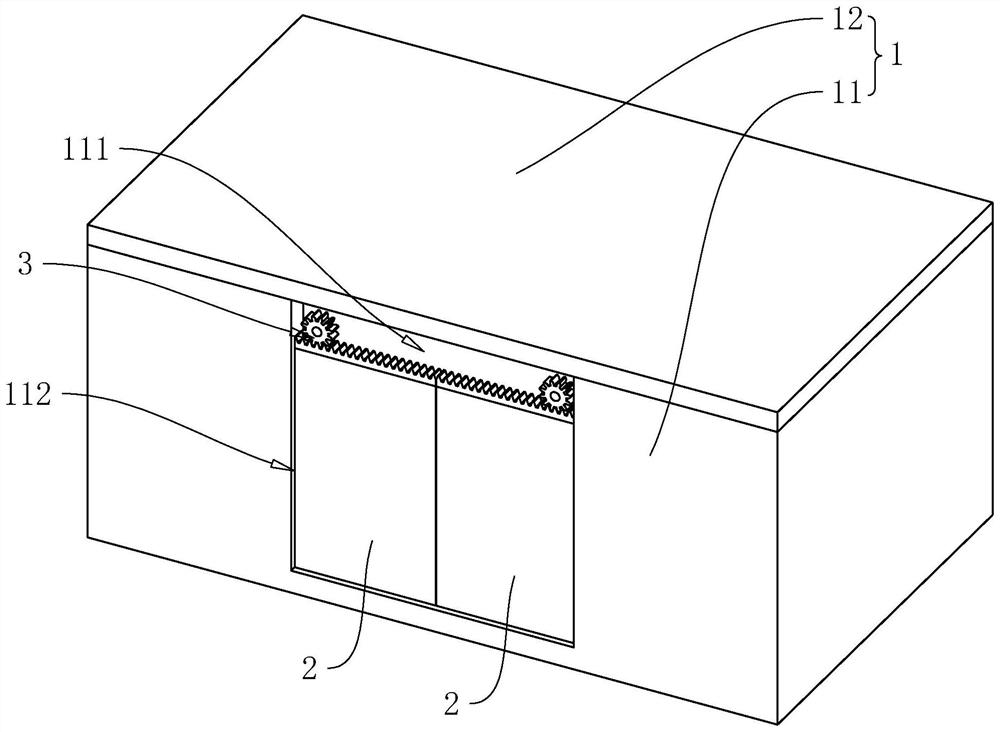

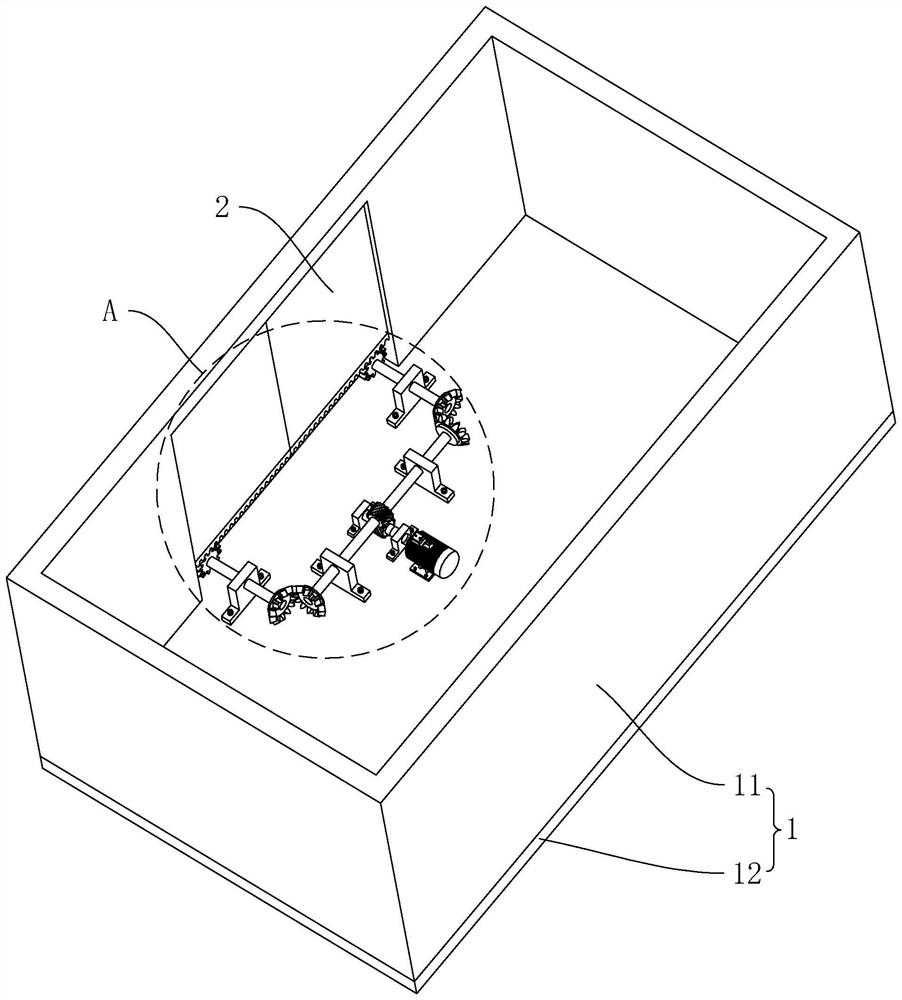

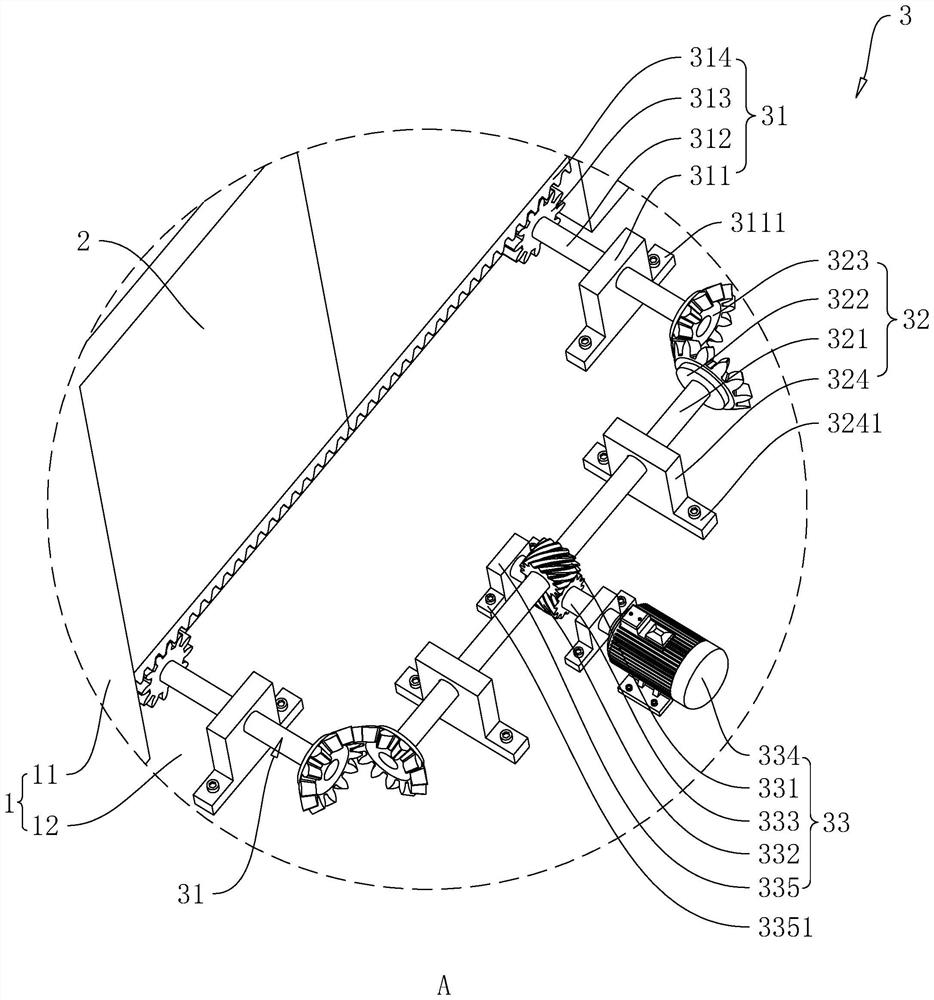

[0050] The embodiment of the present application discloses a basement civil air defense structure installed underground. refer to figure 1 The basement civil air defense structure includes a basement body 1 , the basement body 1 includes a roof 12 and four side panels 11 , and the tops of the four side panels 11 are fixedly connected to the lower surface of the roof 12 . One of the side plates 11 is provided with an entrance and exit 111 and two chute 112 , the two chute 112 are symmetrically distributed on both sides of the entrance and exit 111 , and the explosion-proof doors 2 are slidingly arranged in the two chute 112 . The lower surface of the top plate 12 is provided with a driving mechanism 3 for driving the two explosion-proof doors 2 to slide towards or away from each other, so as to realize the opening and closing of the two explosion-proof doors 2 .

[0051] Continue to refer to figure 1 , in the horizontal direction, the sliding direction of the explosion-proof ...

Embodiment 2

[0063] The difference between embodiment 2 and embodiment 1 is:

[0064] refer to Figure 7 with Figure 8 , the drive assembly 33 includes a worm gear 336, a worm screw 337, a motor 334 and two third support blocks 335; the two third support blocks 335 are fixed on the basement body 1, and the two ends of the worm 337 are respectively connected to the two third support blocks 335 is rotationally connected, the worm gear 336 is sleeved on the linkage rod 321 and is fixedly connected with the linkage rod 321, the worm gear 336 and the worm screw 337 mesh with each other; the motor 334 is fixed on the basement body 1, and the output shaft of the motor 334 is fixed to the end of the worm screw 337 connect. The motor 334 drives the worm 337 to rotate, the worm 337 drives the worm wheel 336 to rotate, and the worm wheel 336 drives the linkage rod 321 to rotate, so that the two explosion-proof doors 2 can slide toward each other or move away from each other; meanwhile, the worm wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com