Hydraulic elevator control system and control method

A control system and elevator technology, applied in the direction of fluid pressure actuation system safety, fluid pressure actuation system components, fluid pressure actuation device, etc., can solve the problem of low degree of automation, low work efficiency, and high labor intensity of skilled workers and other issues to achieve the effect of improving efficiency, avoiding unnecessary losses, and improving automation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

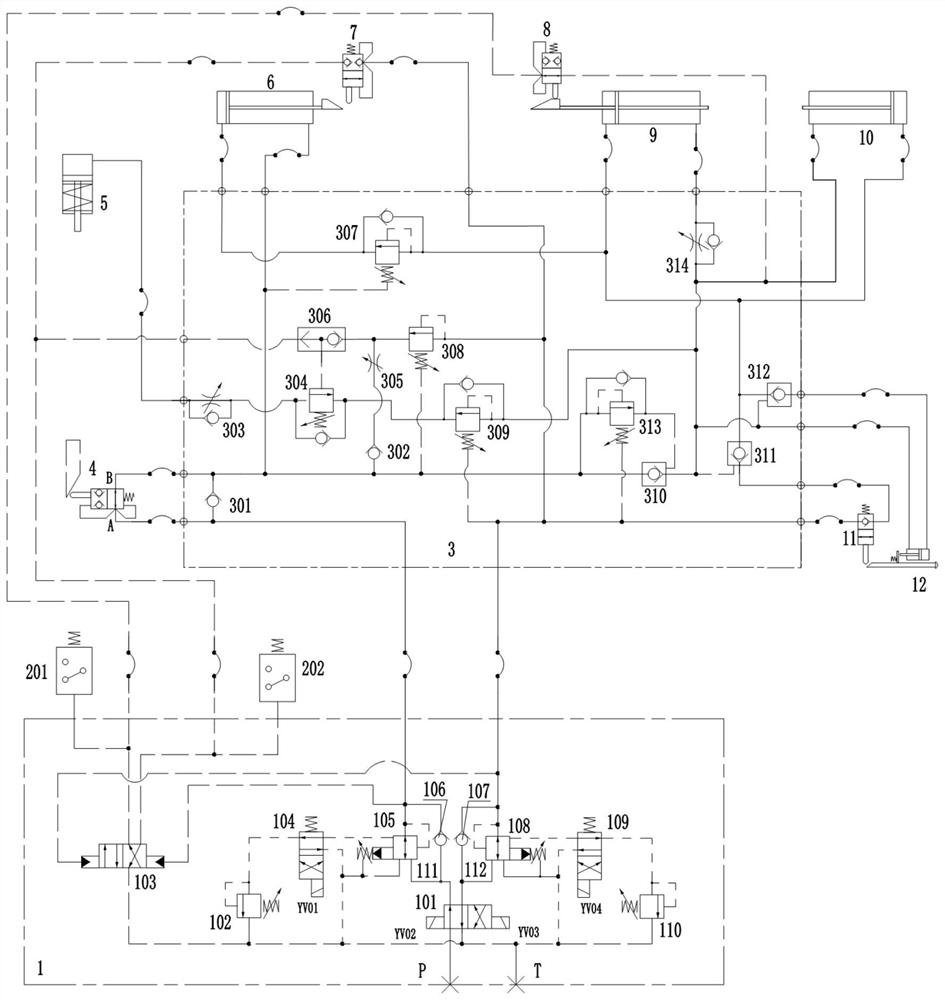

[0058] A hydraulic elevator control system, such as Figure 1 to Figure 6 As shown, it includes the first reversing solenoid valve 101 for controlling the opening / closing of the elevator, and the control oil circuit for controlling the opening / closing of the elevator through the first reversing solenoid valve 101, and the control oil circuit for driving Execute the oil cylinder to control the opening / closing of the elevator;

[0059] The executive oil cylinder includes a first oil cylinder 9 and a second oil cylinder 10, and the first oil cylinder 9 and the second oil cylinder 10 are connected in parallel to the control oil circuit;

[0060] The control oil circuit includes an oil inlet port P and an oil return port T. After the oil inlet port is connected to the first reversing solenoid valve 101, a first oil port 111 and a second oil port 112 are provided. Through the first The reversing solenoid valve 1 controls the first oil passage end 111 and the second oil passage end ...

Embodiment 2

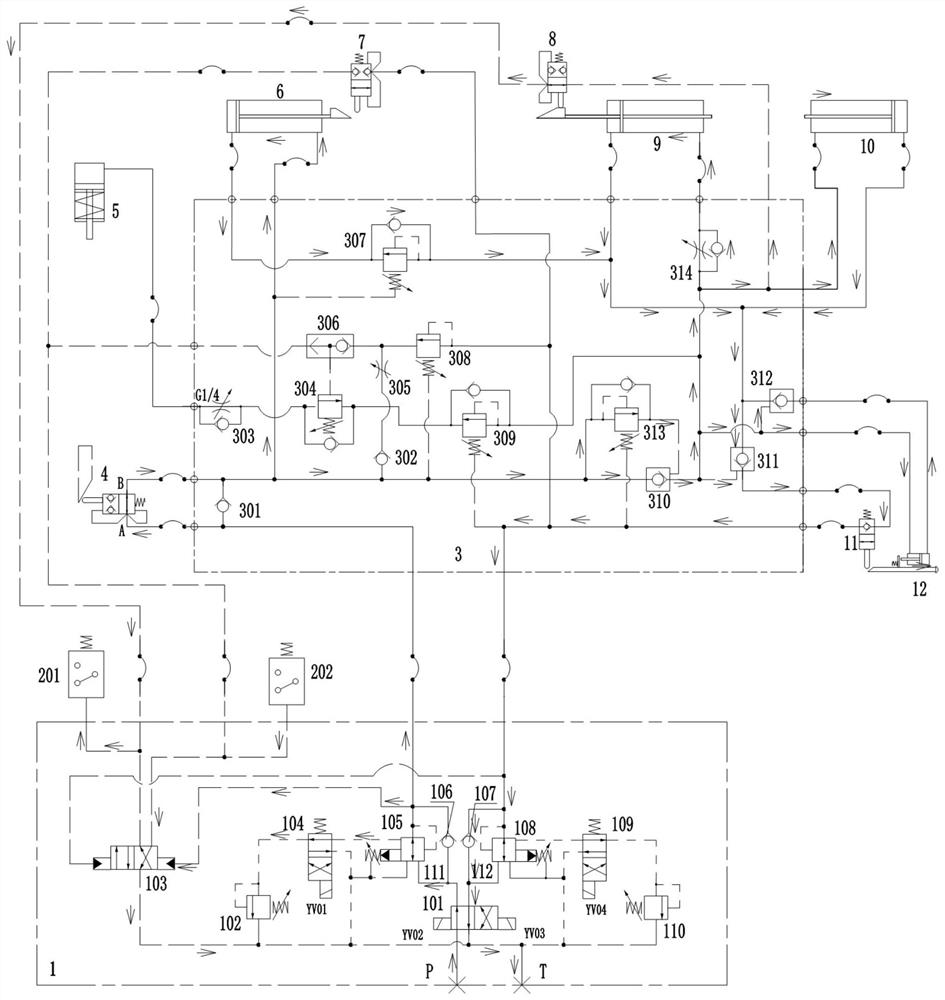

[0097] A hydraulic elevator control method, comprising the following steps:

[0098] Open the elevator;

[0099] Such as figure 2 As shown, the electromagnet YV02 is energized, the elevator starts to open the door, and the first reversing solenoid valve 101 changes direction. The card executes the door opening command; the high-pressure oil circuit passes through the P port of the oil inlet port, and is divided into two branch flows after passing through the first pressure relief valve 105, and the hydraulic direction valve 103 of the branch circuit changes direction, so that the closing signal switch 202 and the return The oil terminal T is connected to complete the pressure relief, and the door closing signal switch 202 controls the door closing signal light to go out; the high pressure oil in the branch circuit 2 passes through the second directional valve 4, and flows to the fourth oil cylinder 6, and the fourth oil cylinder 6 works to open the latch, and the opening of ...

Embodiment 3

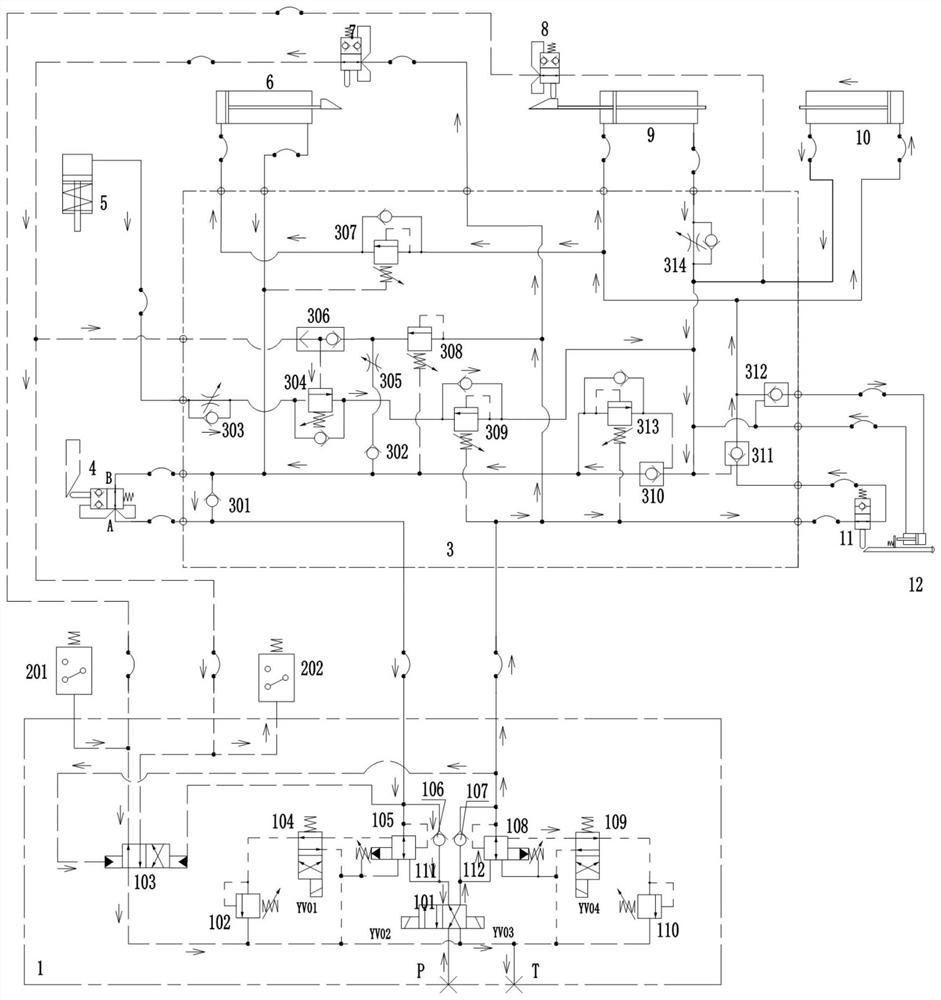

[0104] On the basis of the design of embodiment 2, with Figure 4 For example, it also includes elevator flipping;

[0105] When the elevator door is in the open state and needs to be turned up, the door opening signal is first given to YV02 to be energized, and then the electromagnet YV01 is energized at the same time, the second reversing solenoid valve 104 is reversed under the action of the electromagnet YV01, and the first overflow valve 102 oil At this time, the door opening pressure is determined by the first pressure relief valve 105, the set pressure of the first pressure relief valve 105 is greater than the pressure of the third sequence valve 309, and the high pressure oil passes through the third hydraulic control check valve 310 , the oil circuit passes through the third sequence valve 309, the balance valve 304 and the first one-way throttle valve 303 to the fifth oil cylinder 5, the jaws of the main body of the elevator start to turn up, and when it reaches the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com