Code spraying device for paper package production

A coding and paper-based technology, applied in printing, typewriters, etc., can solve problems such as many manual errors, inconsistent coding positions, and interference with carton processing, so as to reduce labor intensity, increase yield, and avoid work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

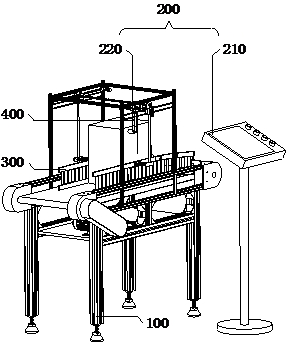

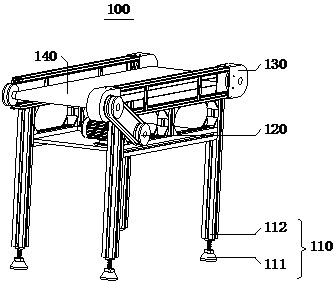

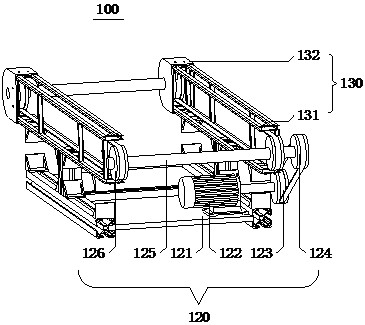

[0049] Such as Figure 1-Figure 12 As shown, a coding device for paper packaging production according to an embodiment of the present application includes: a conveying mechanism 100 , a coding assembly 200 , a fastening mechanism 300 and an adjusting mechanism 400 .

[0050] The coding assembly 200 is arranged on both sides inside and outside the conveying mechanism 100, the fastening mechanism 300 is arranged on the top side of the conveying mechanism 100, the adjusting mechanism 400 is installed on the top side of the conveying mechanism 100 and cooperates with the fastening mechanism 300, the conveying mechanism 100 provides a The mobile platform and the inkjet assembly 200 make manual work into automation, which improves work efficiency and reduces the defect rate of products. The fastening mechanism 300 enables the products on the conveying mechanism 100 to be changed and fastened according to their own width, avoiding In order to prevent the products from being unstable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com