High-temperature and high-pressure sterilization device

A sterilization device, high temperature and high pressure technology, used in water supply devices, sanitary equipment for toilets, heating and other directions, can solve the problem of inconvenient removal of items, and achieve the effects of fast sterilization and simple discharge process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

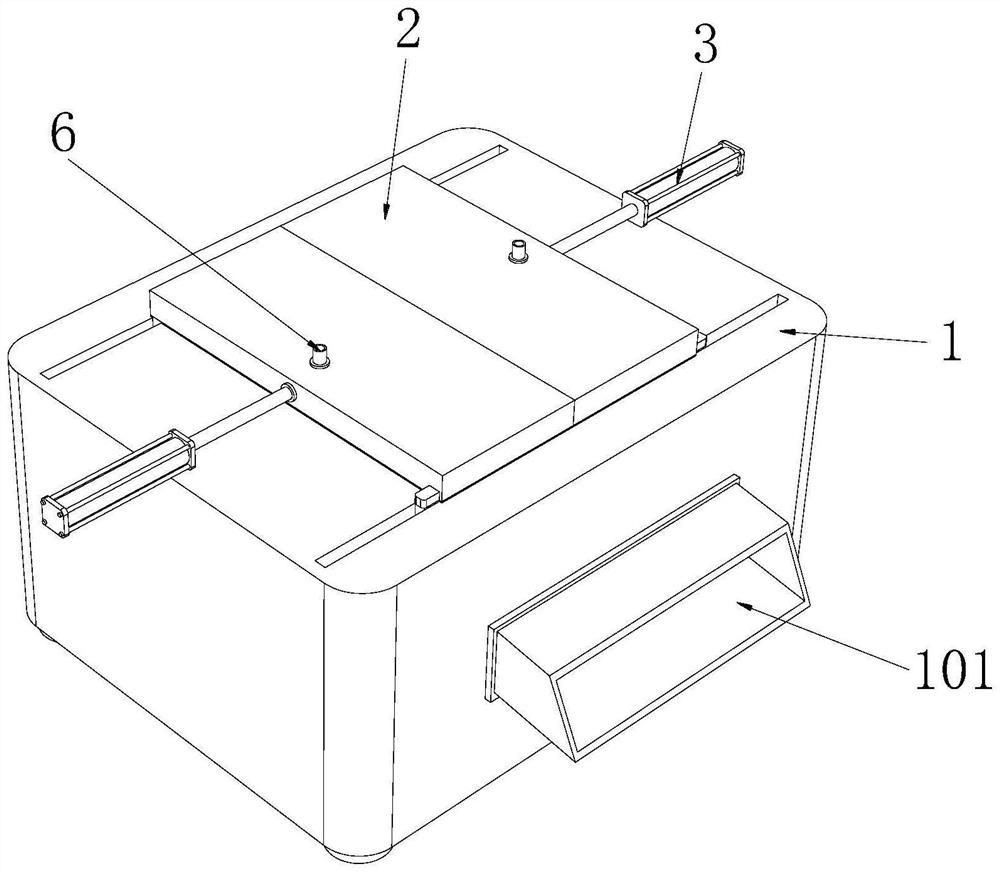

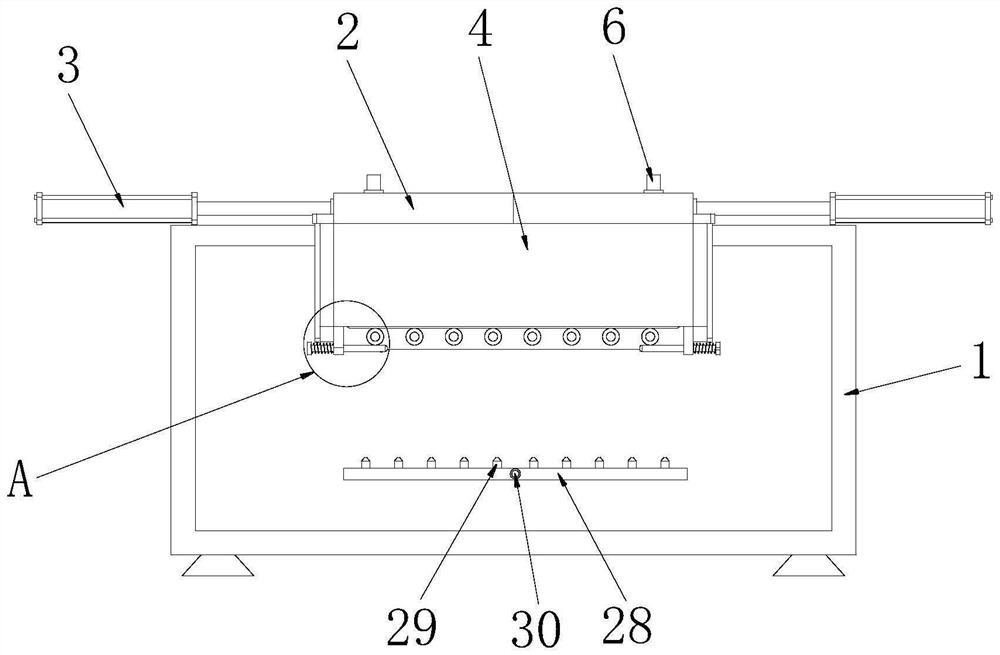

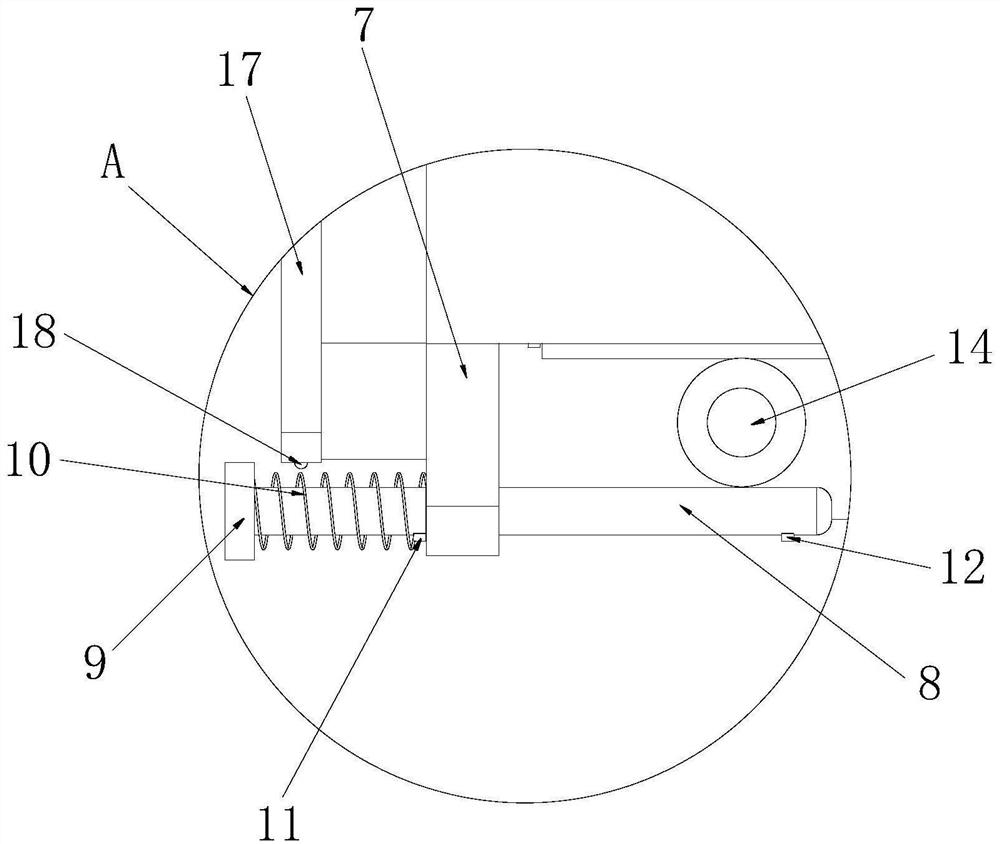

[0031] see Figure 1-7 , in an embodiment of the present invention, a high-temperature and high-pressure sterilization device includes a box body 1, a top cover 2 is provided on the top of the box body 1, and a push element 3 is fixedly installed on the top end of the box body 1. The output end of the element 3 is connected with the transmission of the top cover 2, and the push element 3 is an electric push rod 17, an air cylinder, a hydraulic cylinder, etc. There are two sets of push elements 3 and the top cover 2, and the two sets of push elements 3 are opposite to each other. Setting, the bottom end of the top cover 2 is provided with a plurality of first steam nozzles 5, the frame body 4 is fixedly installed in the box body 1, and the top cover 2 is slidably installed on the top of the frame body 4, so The bottom of the inner cavity of the frame body 4 is rotatably equipped with a plurality of support rods 14, the frame body 4 is provided with a drive mechanism for driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com