Method and device for balancing journal-less rotors

A technology for balancing devices and rotors, applied in static/dynamic balance testing, measuring devices, testing of machine/structural components, etc., can solve problems such as distortion of measurement results, rotor wetting, etc., and achieve the effect of high support rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

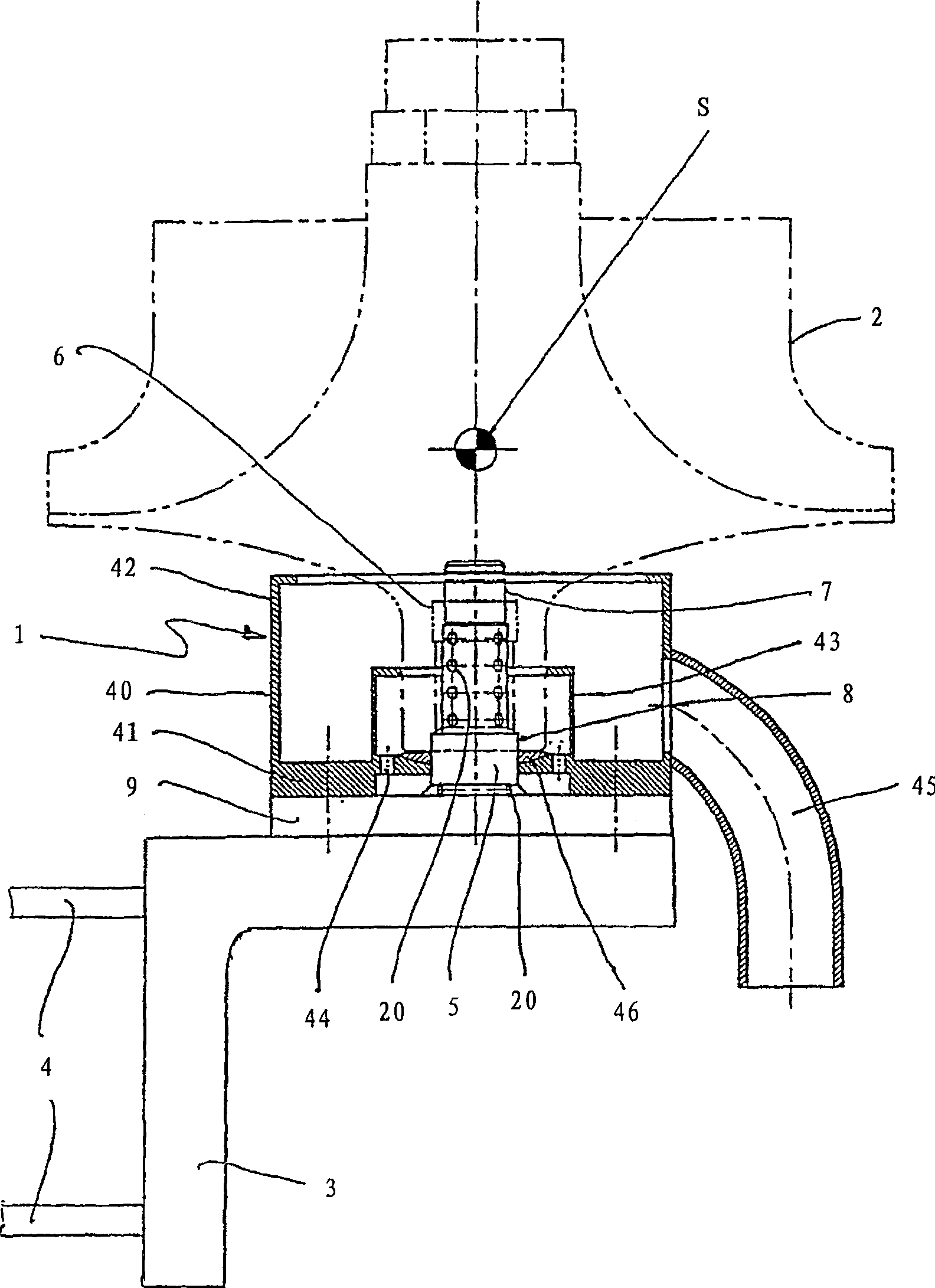

[0020] figure 1 The one shown is used for a rotor 2 to be tested (in figure 1 The support structure 1 represented by dotted line in ) is fixed on the vibrating bridge 3 of a balancing device. The vibrating bridge 3 is usually supported in a vibrating manner relative to the balancing device frame, eg on four support springs 4 (only two of which are shown in the figure). A drive mechanism (not shown in the figure) rotates the rotor 2 . The vibration of the vibrating bridge 3 caused by the unbalance is measured and the measured value of the vibration is used to determine the unbalance on the rotor 2 to be balanced.

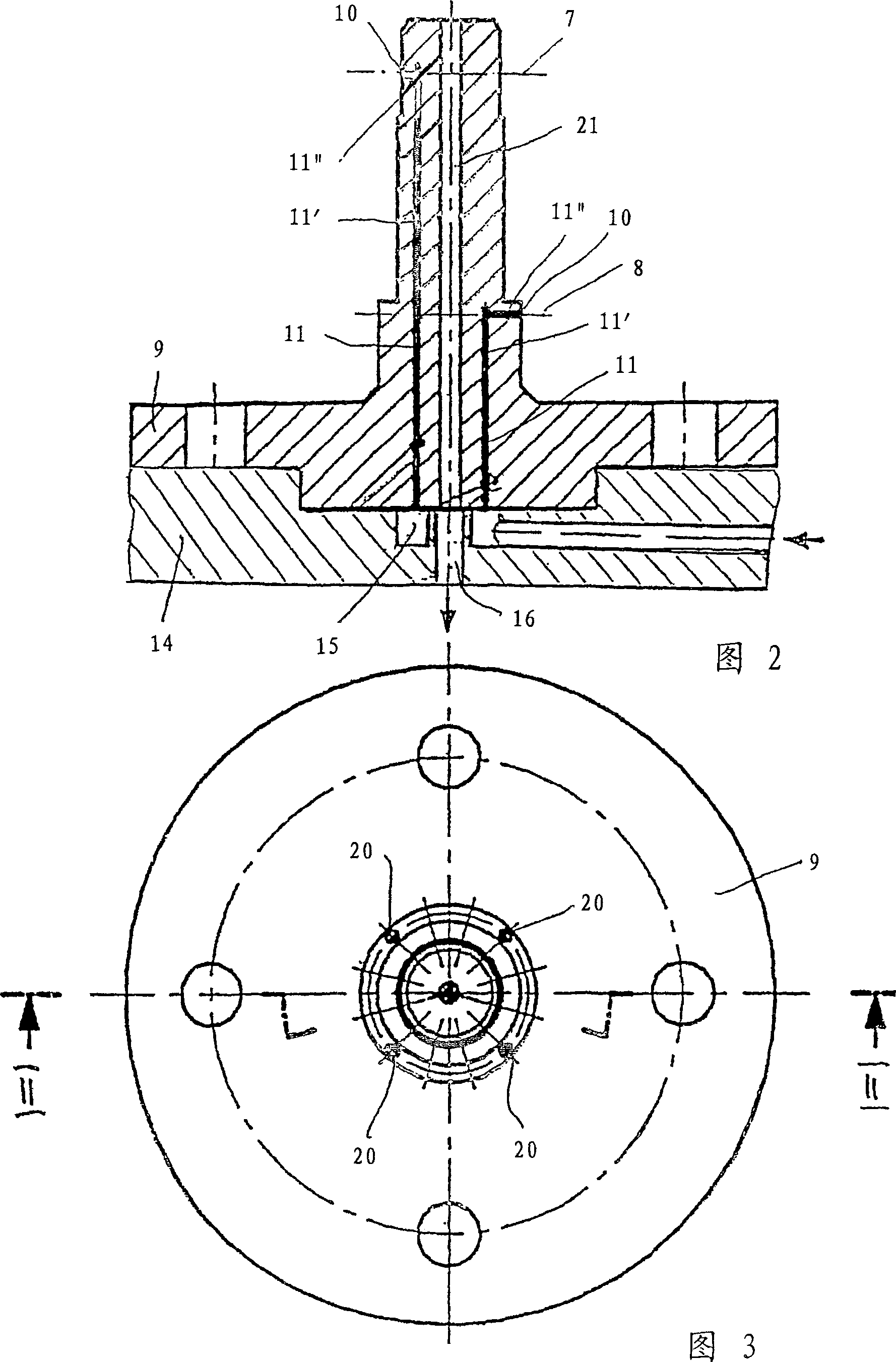

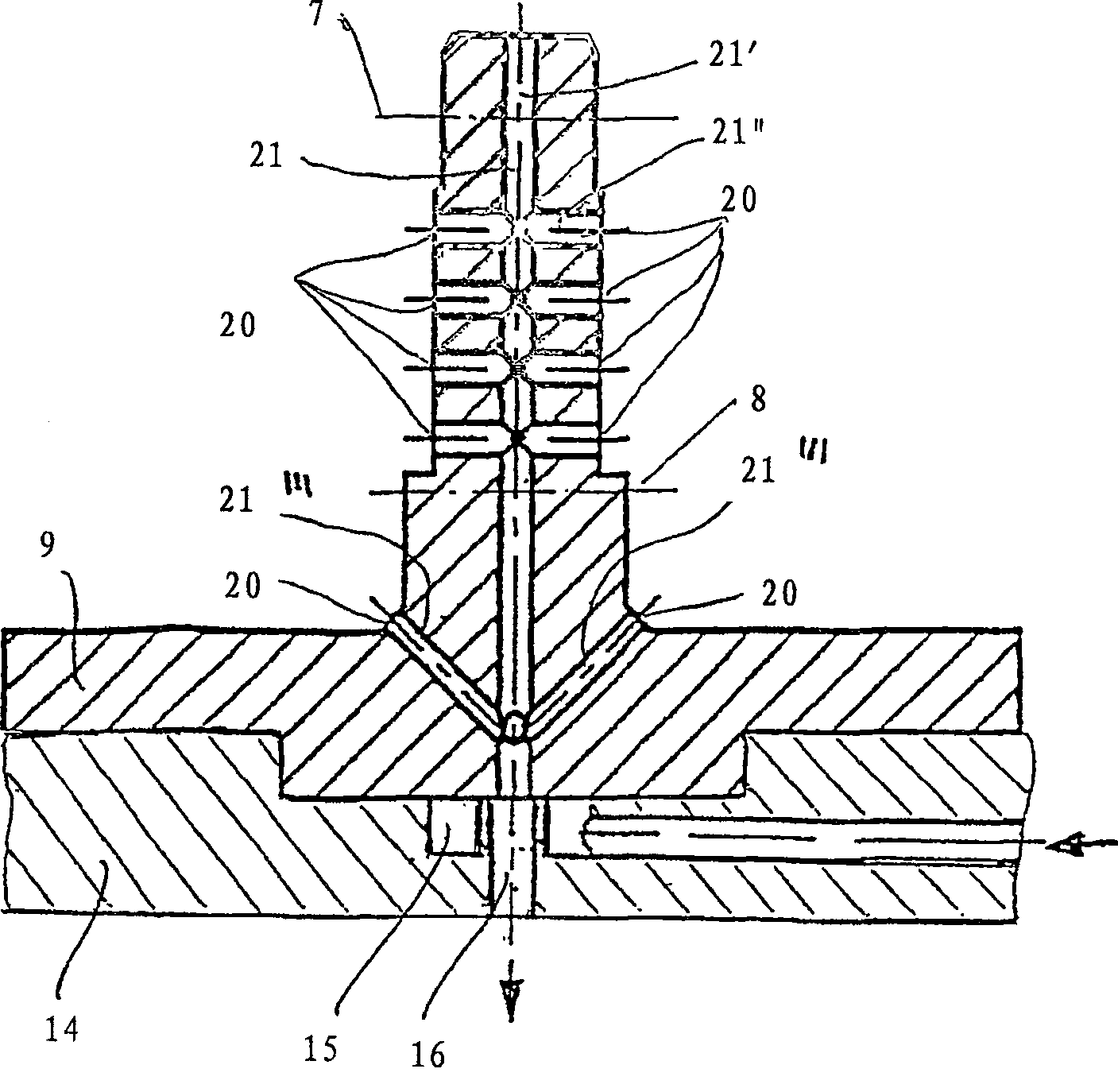

[0021] The bearing structure has a bearing spindle 5 on which the rotor 2 to be tested or balanced is rotatably mounted.

[0022] exist figure 1 In the embodiment shown, the rotor 2 has a central rotor opening 6 which does not pass through, ie a blind bore, and is supported by means of this bore on a vertically arranged bearing mandrel 5 . The center of gravity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com