Desulfurization gypsum drying and calcining production process

A technology for desulfurization gypsum and production process, applied in the field of gypsum treatment, can solve the problems of inability to realize heat recycling, increase of human, material and financial resources, heat loss to the environment, etc., and achieve the effects of improving dust removal effect, stabilizing thermal efficiency and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

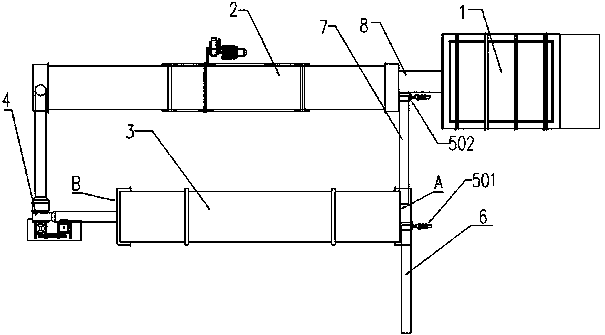

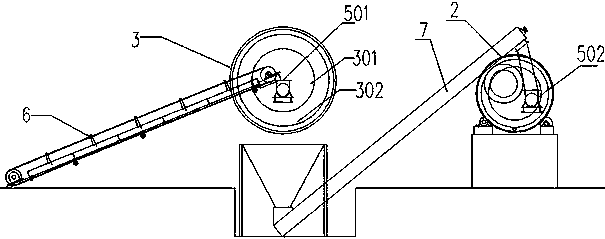

[0029] Desulfurization gypsum drying and calcining equipment, such as figure 1 , 2 As shown in the figure, it includes a post-combustion hot gas generator as a heat source (here specifically refers to a post-combustion hot gas generator with a patent number of 201210302219.8) 1, a drying drum 3, a calcining drum 2, a screw conveyor 7, a belt conveyor 6, The first screw feeder 501, the second screw feeder 502 and the induced draft fan 4, the described afterburning hot gas generator and the calcining drum are connected through the hot air pipe 8; The double-layer drum of the first layer, the lifting plate set in the inner layer drum 301 is opposite to the inclination direction of the lifting plate set in the outer layer drum 302, and the outer layer drum is 1 meter longer than the inner layer drum, at the distance from the end of the drying drum (that is, end B in the figure) the position of 1 meter is the end of the inner drum, the lifting plate of the inner drum is inclined d...

Embodiment 2

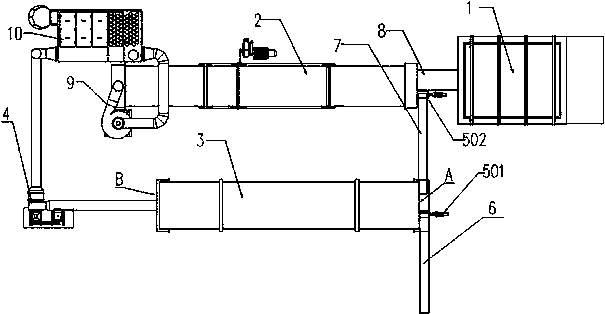

[0034] Desulfurization gypsum drying and calcining equipment, such as figure 2 , 3 As shown, the difference from the first embodiment above is that the equipment also includes a cyclone dust collector 9 and a bag filter 10, the calcining drum is connected to the gas inlet of the cyclone dust collector, and the gas outlet of the cyclone dust collector is connected to the bag filter The gas inlet of the filter is socketed, and the gas outlet of the bag filter is socketed with the air inlet of the induced draft fan.

[0035] The operation process of the heat source is as follows: the heat source generated in the continuous combustion hot gas generator first enters the calcining drum through the hot air pipe. After the calcining drum is calcined, the induced draft of the induced draft fan generates wind pressure, so that the exhaust gas enters the cyclone dust collector for dust removal, and then in the The dust is further removed in the bag filter, and finally the pure and dust-f...

Embodiment 3

[0038] Desulfurized gypsum drying and calcining production process, the process uses desulfurized gypsum drying and calcining equipment to make desulfurized gypsum into β hemihydrate gypsum, and the desulfurizing gypsum drying and calcining equipment is the desulfurized gypsum drying and calcining equipment described in Example 1, here No more details, the steps of the process are as follows:

[0039] Step S01: the belt conveyor pre-conveys the desulfurized gypsum to the first screw feeder, and the first screw feeder feeds the desulfurized gypsum into the inner drum of the drying drum;

[0040] Step S02: The subsequent combustion hot gas generator supplies the heat source for the calcining drum, and the heat source in the calcining drum is pumped into the drying drum by the induced draft fan;

[0041] Step S03: drying the desulfurized gypsum in the inner drum of the drying drum, the drying temperature is 200°C, the drying time is 60 minutes, and the product after drying is des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com