Porous thread twisting device of injection mold

An injection mold and twisting technology, applied in the field of mold manufacturing, can solve the problems of small spacing between screw cores, transmission mechanism conflict or interference, etc., and achieve the effects of reasonable structure, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

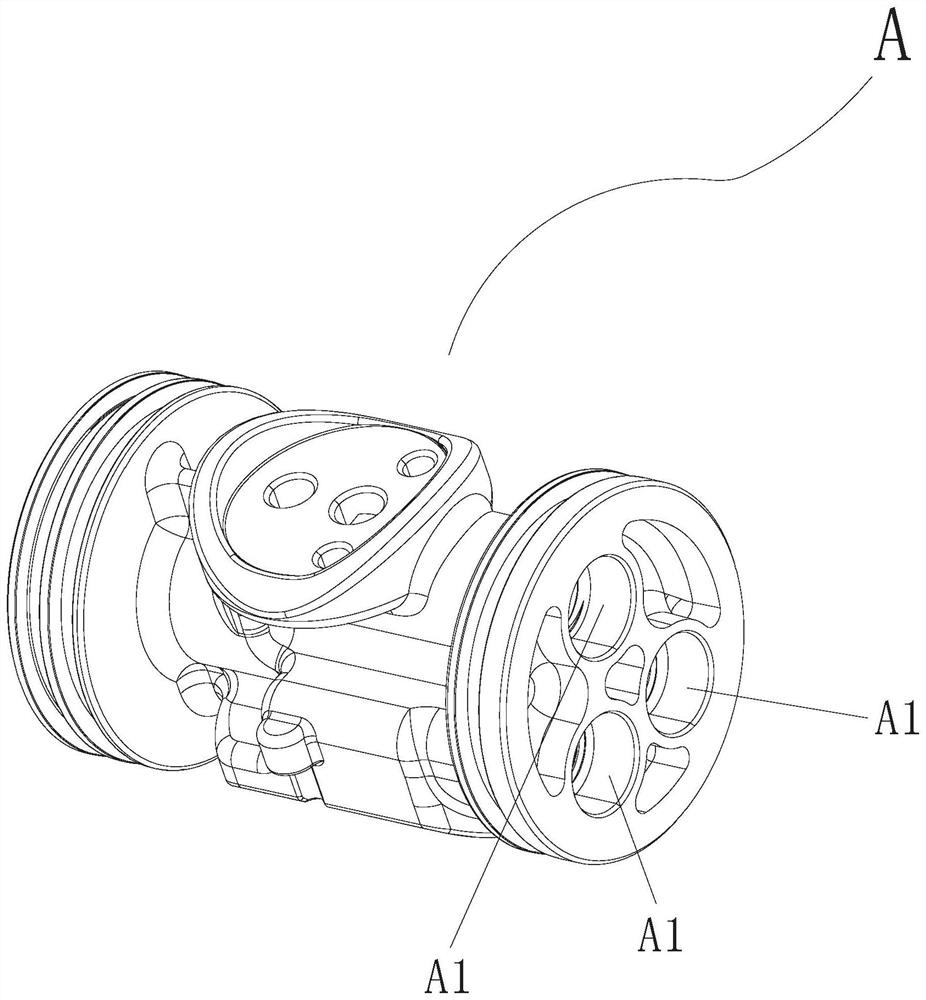

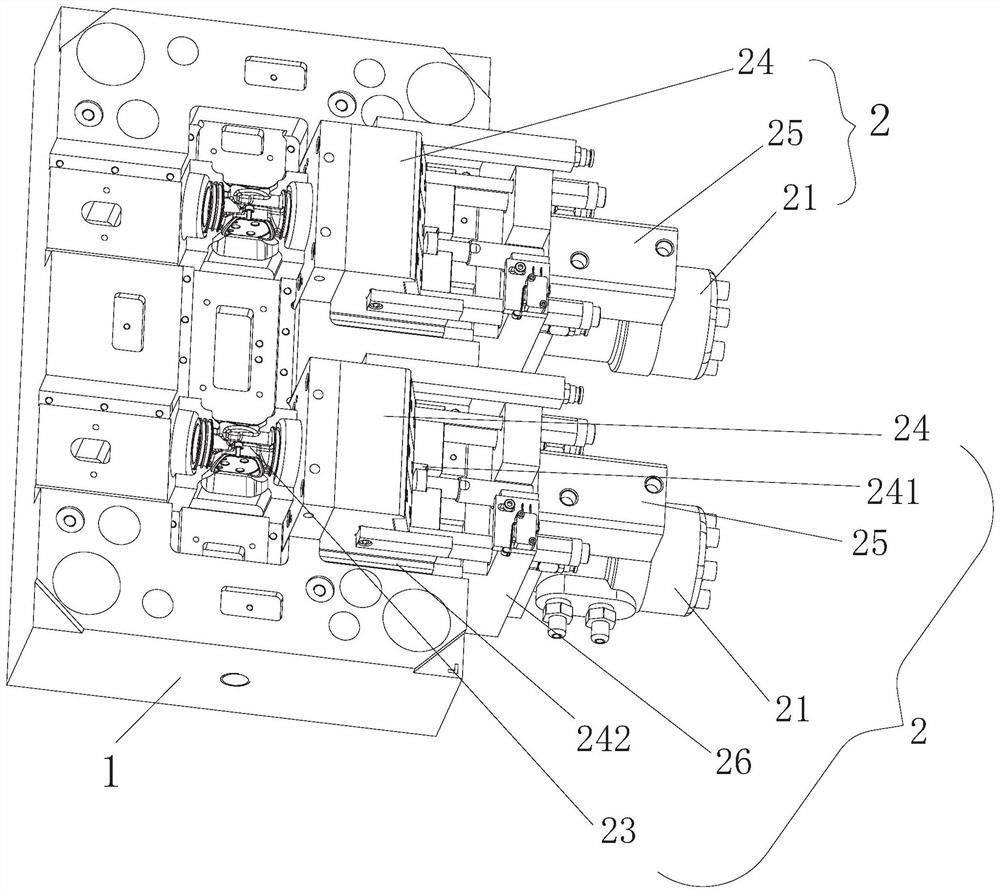

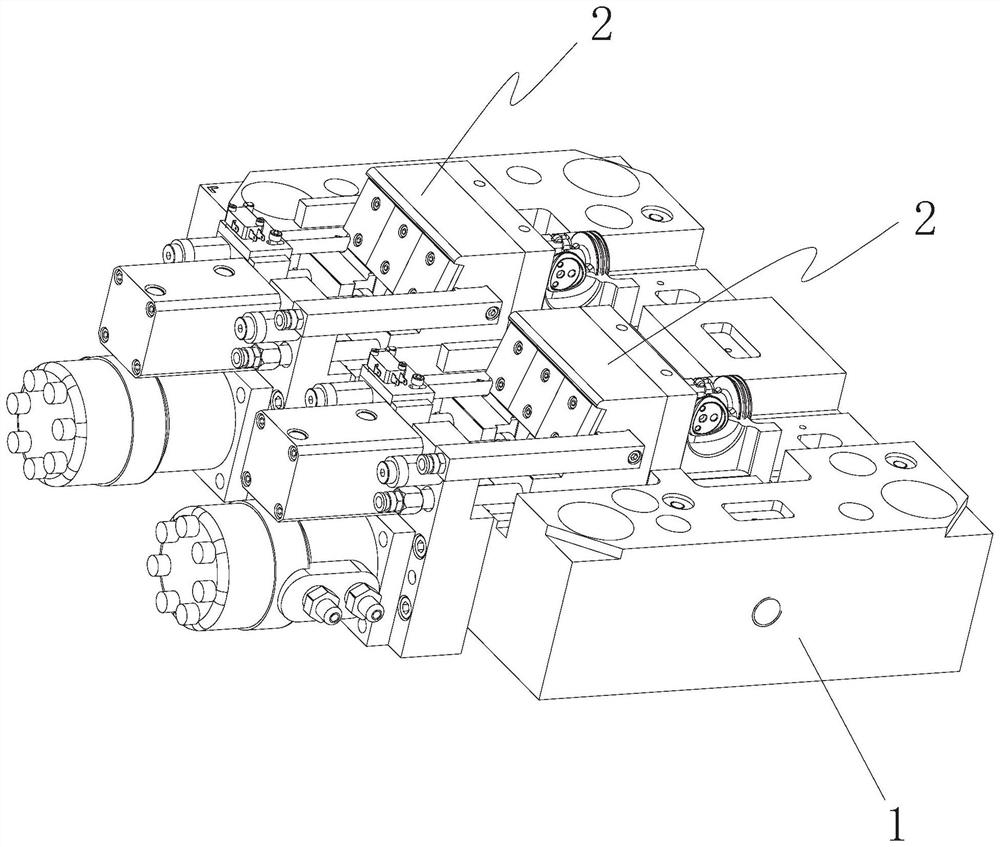

[0026] Example: see Figure 1 to Figure 7 , a kind of multi-hole twisting device for injection mold, comprising a rear mold 1, the rear mold 1 is provided with a cavity matched with the front mold for forming injection molding products, the rear mold 1 is provided with a twisting mechanism 2, and the twisting mechanism includes a first A drive unit 21, a transmission unit 22 and at least three tooth cores 23, the first drive unit 21 synchronously drives each tooth core 23 to rotate through the transmission unit 22, and the front end of each tooth core 23 extends into the mold cavity to carry out the twisting operation, so Described transmission unit 22 comprises ring gear 221 and matched tooth core gear 222, and the quantity of tooth core gear 222 corresponds to tooth core 23 one by one, and ring gear 221 central through hole is provided with internal teeth along the circumference of through hole, and tooth core gear 222 is disposed in the through hole and meshes with the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com