Electric-induced curing method and curing equipment for concrete structures in negative temperature environment

A technology for concrete structures and concrete specimens, which is applied in building construction, ohmic resistance heating parts, and processing of building materials, etc. It can solve problems such as lack of control, achieve resistance reduction, high-quality and stable structural performance, and avoid penetration crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

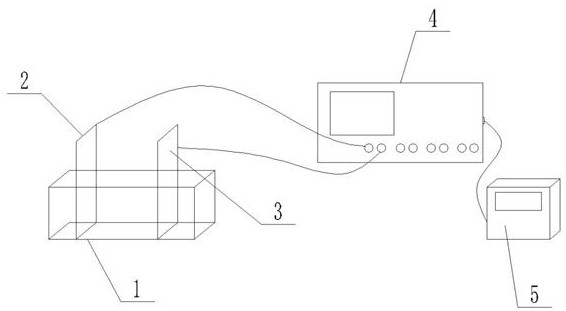

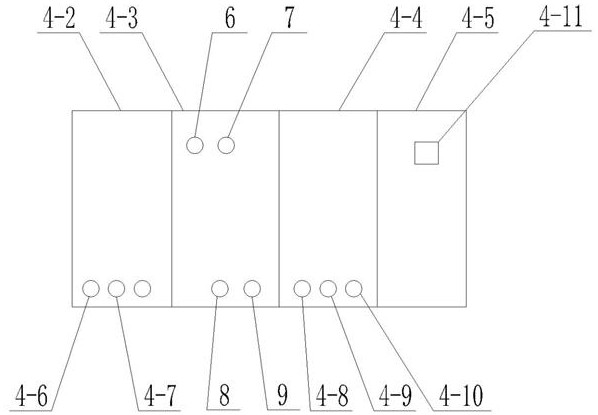

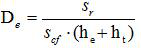

[0049] Specific implementation mode one: combine figure 1 and figure 2 Describe this implementation mode. In this implementation mode, during the maintenance process in a negative temperature environment, when the concrete structure is a concrete structure without conductive fillers, the electrical excitation is determined by the ratio of the concrete structure resistance during the maintenance process to the initial resistance of the concrete structure. The quality control point of curing concrete specimens, when the concrete structure reaches the quality control point, the adjustment operation of the electric power of the concrete specimens is started, so as to achieve the crack-free electric excitation required by the curing temperature of the concrete structure in the fresh mixing stage and hardening stage. maintenance process.

specific Embodiment approach 2

[0050] Specific embodiment 2: This embodiment is a further limitation of specific embodiment 1. After determining the quality control point of the electro-cured concrete specimen according to the ratio of the concrete structure resistance in the curing process to the initial resistance of the concrete structure, the concrete specimen is opened. The adjustment operation of the energized power, the adjustment operation process is:

[0051] Combining the curing temperature requirements of the concrete structure in the fresh stage and hardening stage with the balance formula of heat generation and heat release, the power-on power is calculated;

[0052] The curing temperature requirements of the concrete structure in the fresh mixing stage and hardening stage are to determine the initial curing temperature of the concrete structure according to the specific ambient temperature, and ensure that the difference between the temperature of the concrete structure itself and the ambient t...

specific Embodiment approach 3

[0059] Specific embodiment 3: This embodiment is a further limitation of specific embodiment 1 or 2. When the quality control point of the electro-cured concrete specimen is reached, the curing temperature adjustment process of the concrete structure can be adjusted by adjusting the power of the concrete structure correspondingly. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com