Sheet type building material rebound value detection device

A technology for building materials and testing devices, which is used in measuring devices, analyzing materials, testing material hardness, etc., and can solve problems such as accurate data and inaccurate testing that cannot well understand the rebound value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

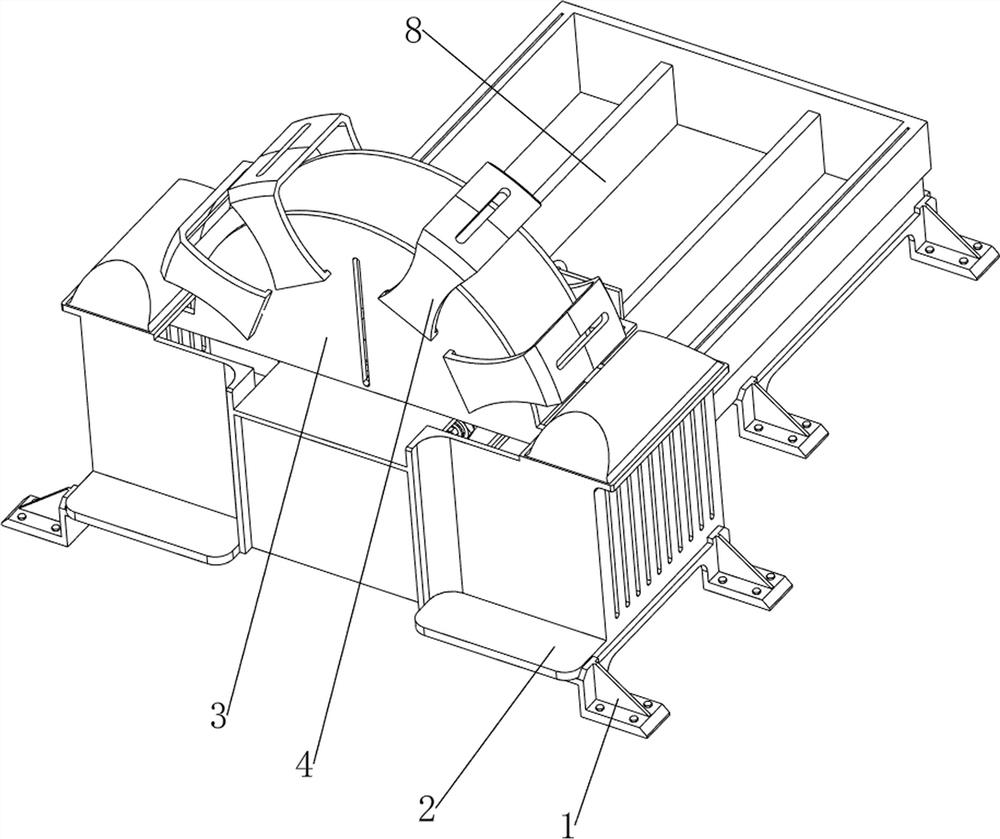

[0037] A device for detecting springback value of thin-plate building materials, such as Figure 1-4 As shown, it includes a support column 1, a frame body 2, an arc plate 3, a first connecting rod 4, a first fixed column 5, a cylinder 6, a pallet 7, a first slide rail 8, a clamping mechanism 9 and a knocking mechanism. Mechanism 10, a plurality of support columns 1 are symmetrically arranged on the left and right sides of the bottom of the frame body 2, and arc-shaped plates 3 are symmetrically arranged between the inner walls of the left and right sides of the frame body 2, and the two arc-shaped plates 3 are connected with A plurality of first connecting rods 4, the front side of the inner bottom of the frame body 2 is symmetrically provided with the first fixed column 5, the cylinder 6 is connected between the two first fixed columns 5, and the left and right symmetrical type is arranged at the inner bottom of the frame body 2 The first slide rail 8, between the first slid...

Embodiment 2

[0040] On the basis of Example 1, such as Figure 5-8 As shown, the clamping mechanism 9 includes a splint 91, a first linear spring 92 and a limit plate 93. The upper part of the supporting plate 7 is symmetrically slid left and right to be provided with a splint 91. Two clamping plates 91 and the supporting plate 7 are connected The first linear spring 92 and the top of the supporting plate 7 are symmetrically provided with a limit plate 93 front and back.

[0041] The user can manually move the clamping plate 91 upwards to keep the clamping plate 91 in the upward moving state, so that in the initial state, the first linear spring 92 is stretched, and the user can place the material to be tested on the clamping plate 91 and the supporting plate 7, and then no force is applied to the splint 91. Under the reset action of the first linear spring 92, the splint 91 moves downward to clamp and fix the material, and the limit plate 93 can assist the material to be placed on the pal...

Embodiment 3

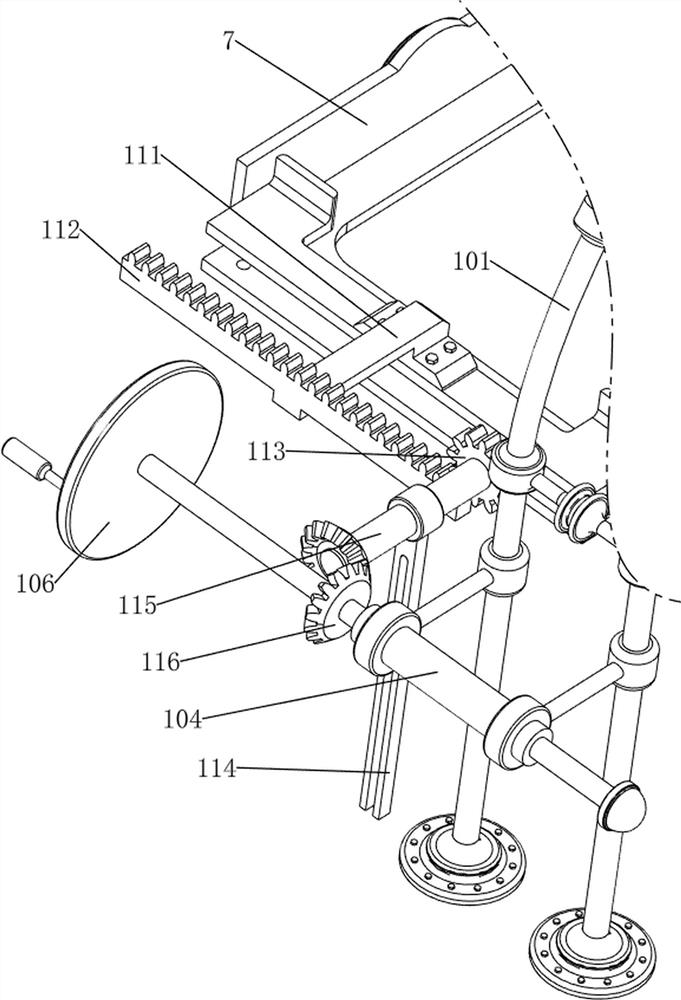

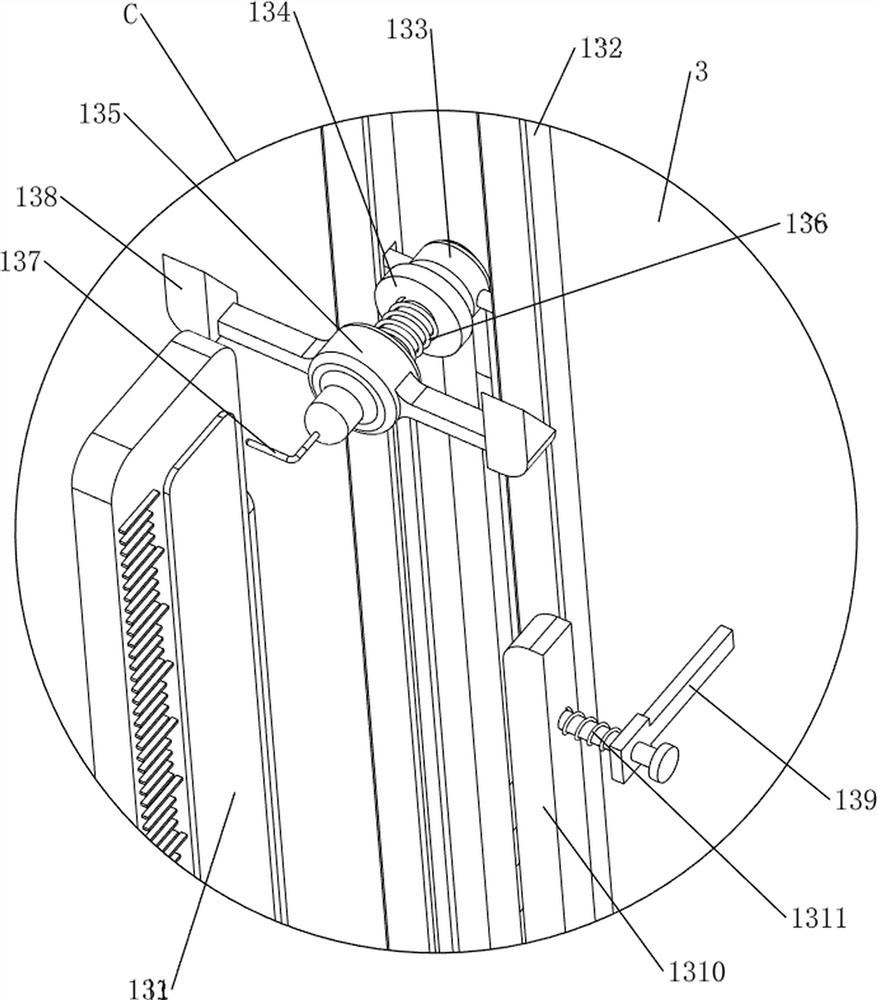

[0045] On the basis of Example 2, such as Figure 9-17 As shown, a wire take-up mechanism 11 is also included, and the wire take-up mechanism 11 includes a fourth fixed column 111, a rack 112, a one-way gear 113, a fifth fixed column 114, a second rotating shaft 115 and a bevel gear set 116, and a splint 91 The fourth fixed column 111 is arranged in the middle of the top, and the outer side of the fourth fixed column 111 is connected with a rack 112. The left and right sides of the bottom front side of the frame body 2 are symmetrically provided with the fifth fixed column 114, and the upper side of the fifth fixed column 114 is arranged The rotary type is provided with a second rotating shaft 115, and the inside of the second rotating shaft 115 is rotated to be provided with a one-way gear 113. The one-way gear 113 meshes with the rack 112, and the second rotating shaft 115 on both sides is respectively connected to the adjacent first rotating shaft 104. A bevel gear set 116 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com