Enhanced water injection oil extraction device and method for ultra-deep fracture-cavity type reservoir oil well

An oil production device and oil well technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve problems such as large development costs, and achieve the effects of improving efficiency, saving supporting construction costs, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

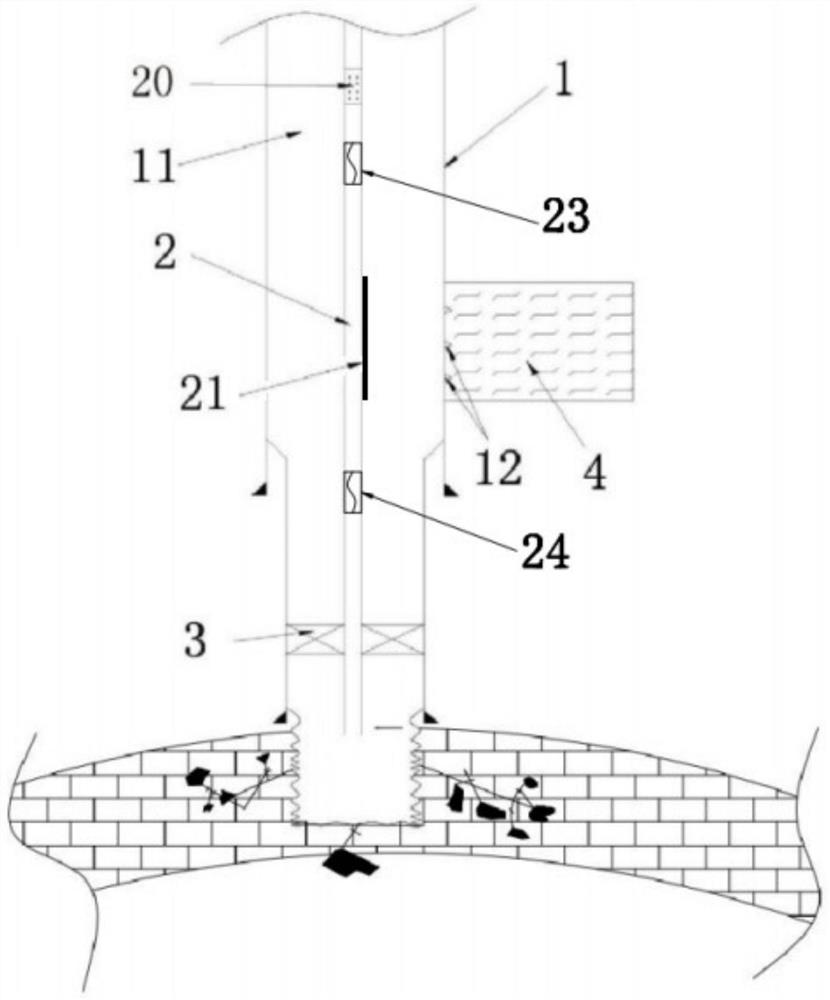

[0025] One of the specific implementations of an enhanced water injection oil recovery device for an ultra-deep fracture-cavity reservoir oil well of the present application, such as figure 1 As shown, it includes tubing 2, packer 3 and casing 1. In this embodiment, the casing 1 is set in the oil well, and the bottom end of the tubing 2 is inserted into the casing 1 and connected with the packer 3 . When the packer 3 is set, the outer peripheral side of the packer 3 is in close contact with the inner wall of the casing 1 . An annulus 11 is formed between the tubing 2 and the casing 1 , and the packer 3 is arranged in the annulus 11 and sheathed on the outer peripheral side of the tubing 2 . There is a high-pressure water layer 4 outside the oil well, and the casing 1 communicates with the high-pressure water layer 4 through perforation. The perforation 12 penetrates the casing 1 and goes deep into the rock formation in the high-pressure water layer 4 . The tubing portion of ...

Embodiment 2

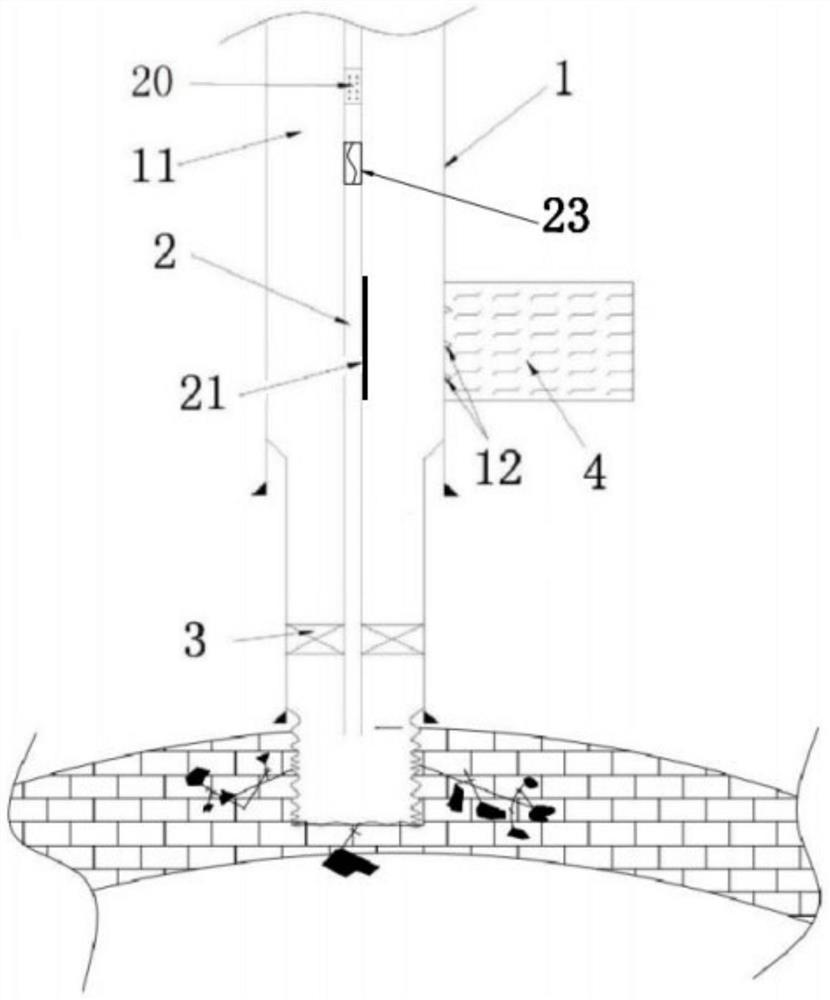

[0043] The second specific implementation mode of the enhanced water injection and oil production device of the ultra-deep fracture-vug reservoir oil well of the present application, see figure 2 As shown, the main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the oil production pump 24 is not needed in the tubing 2 of this embodiment, but only the downhole water injection pump 23 is provided, so that the oil production work can be carried out by means of blowout, while the downhole water injection pump 23 can still Play the role of increasing the water injection effect.

Embodiment 3

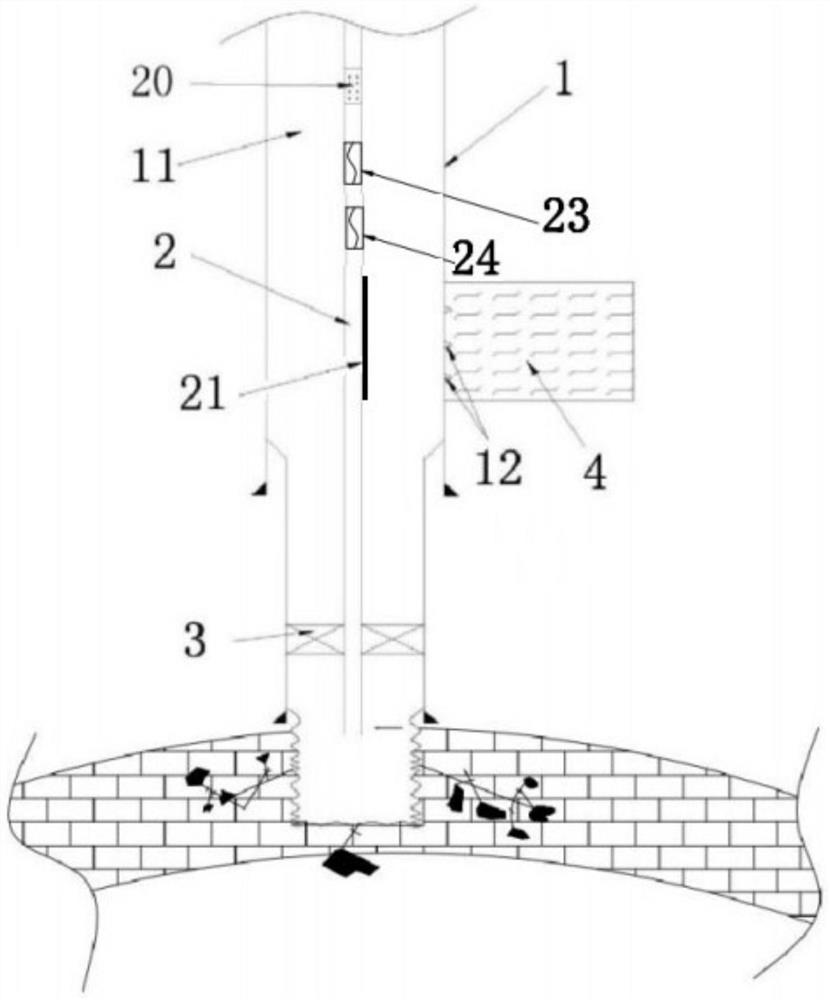

[0045] The third specific implementation mode of the enhanced water injection and oil recovery device for the ultra-deep fracture-vug reservoir oil well of the present application, see image 3 As shown, the main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is: the oil production pump 24 and the downhole water injection pump 23 in the oil pipe 2 of the present embodiment are all arranged above the high pressure water layer 4, which is more convenient for the oil production pump 24 and the downhole water injection pump 23. control and installation. It should be noted that, in essence, the positions of the oil production pump 24 and the downhole water injection pump 23 can be selected and set according to actual needs, as long as they are installed in the oil pipe without affecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com