Self-flow water injection device and method for ultra-deep fracture-cavity type reservoir oil well

A self-flowing water injection and oil well technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of high development cost, etc., and achieve the effect of improving efficiency, saving development investment or cost, and saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present application is further described in conjunction with the following examples.

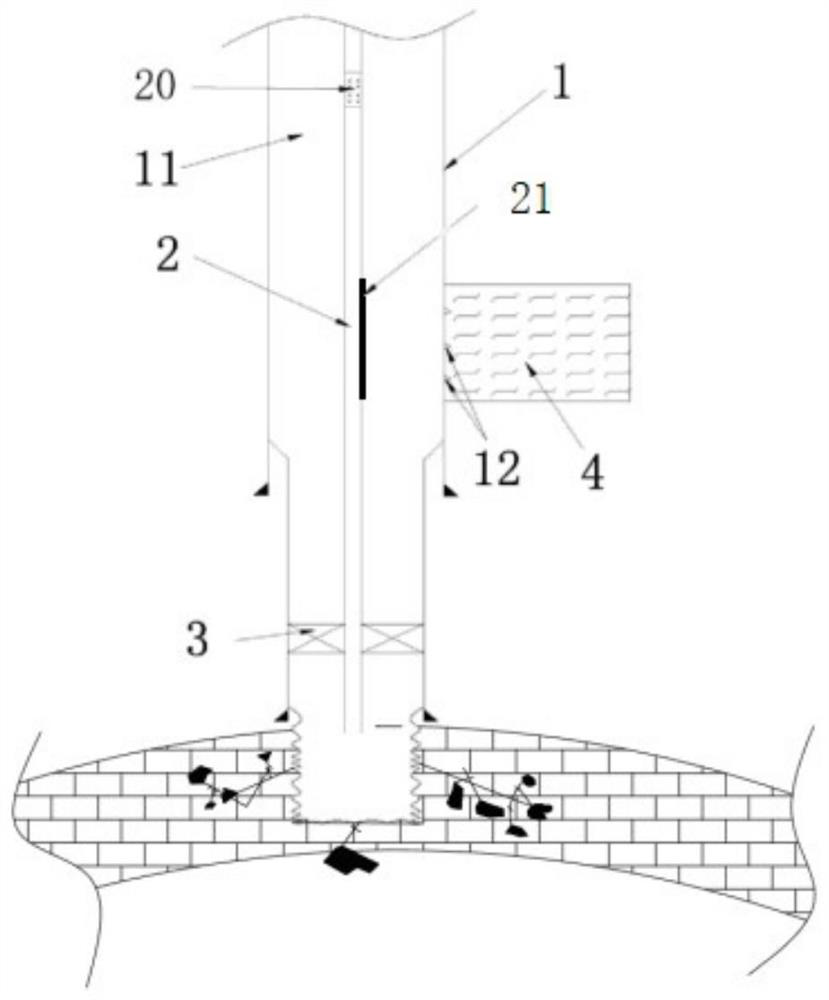

[0022] A specific embodiment of the self-flowing water injection device for an ultra-deep fracture-cavity reservoir oil well of the present application, as figure 1 As shown, it includes tubing 2, packer 3 and casing 1. The casing 1 is set in an oil well, which is a vertical shaft in the prior art and can be constructed by a well completion string. The completion string includes components such as the completion string body, drill pipe, packer, perforator, and temporary plugging ball seat. It can be drilled in stages and casings of different specifications can be added in stages to form a multi-level stepped oil well. . When drilling, the completion string lowers the drill pipe and packer into the casing, pressurizes the drill pipe to make the packer seat seal and the casing form a seal and fix, and there is a set between the packer and the drill pipe. Throw away the structure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com