High-performance mold and preparation process thereof

A preparation process and high-performance technology, applied in the direction of metal material coating process, manufacturing tools, heat treatment equipment, etc., can solve the problems of long delivery time, unsatisfactory toughness, and expensive imported steel, so as to reduce costs and meet service requirements. The effect of using demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with various embodiments, but it should be noted that these embodiments are not limitations of the present invention, and those of ordinary skill in the art can make functional, method, or structural equivalent transformations or replacements based on these embodiments. , all fall within the protection scope of the present invention.

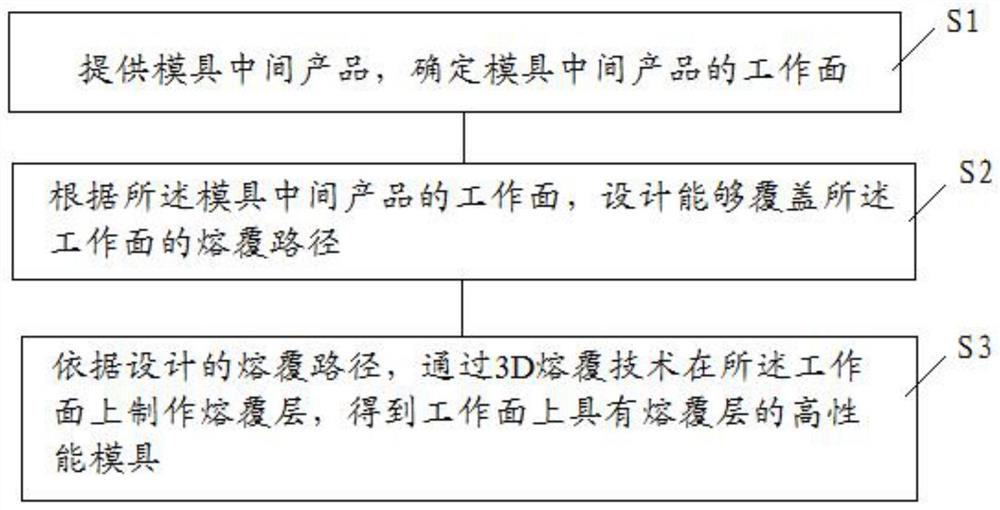

[0021] The invention provides a high-performance mold preparation process, which includes:

[0022] Provide mold intermediate products and determine the working surface of mold intermediate products;

[0023] According to the working surface of the mold intermediate product, designing a cladding path capable of covering the working surface;

[0024] According to the designed cladding path, a cladding layer is made on the working surface through 3D cladding technology, and a high-performance mold with a cladding layer on the working surface is obtained.

[0025] The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com