Paddle performance detection equipment for simulating actual use process

A technology for testing equipment and paddles, which is applied in the field of paddles, can solve problems such as paddle damage and poor reliability, and achieve the effect of avoiding the outflow of unqualified products and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

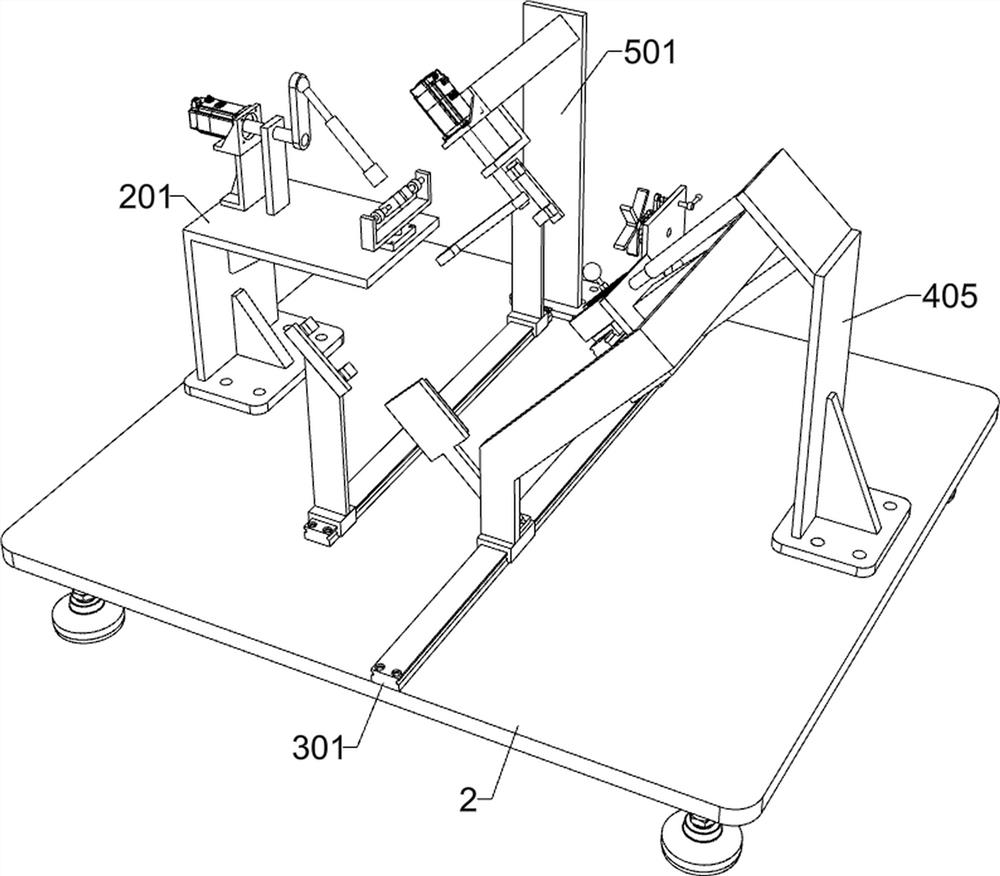

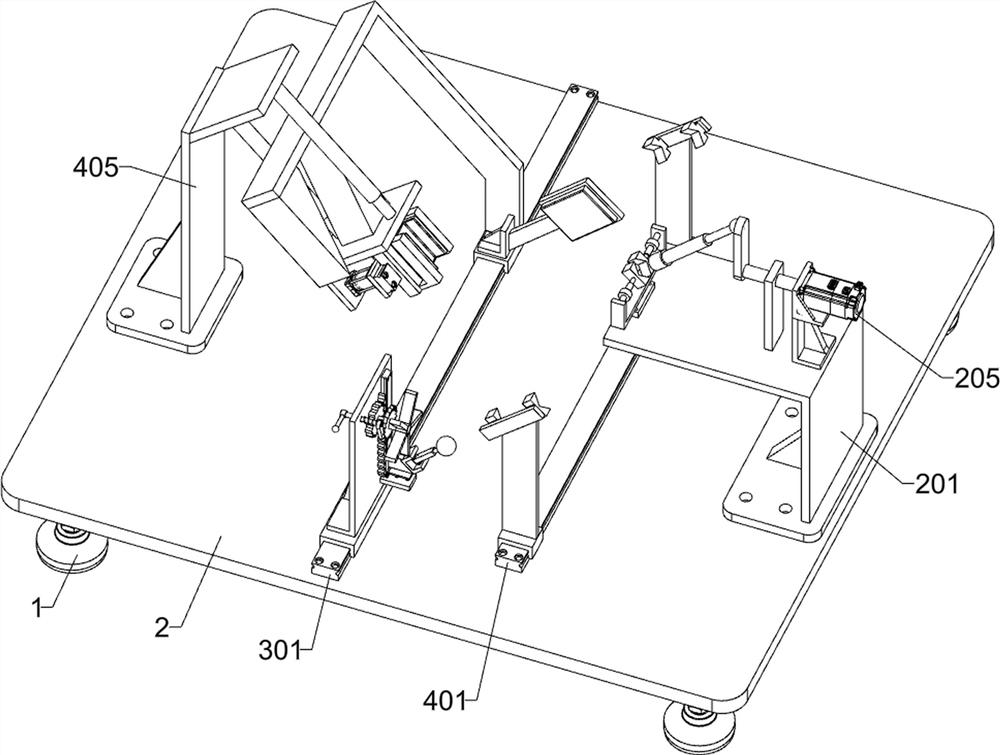

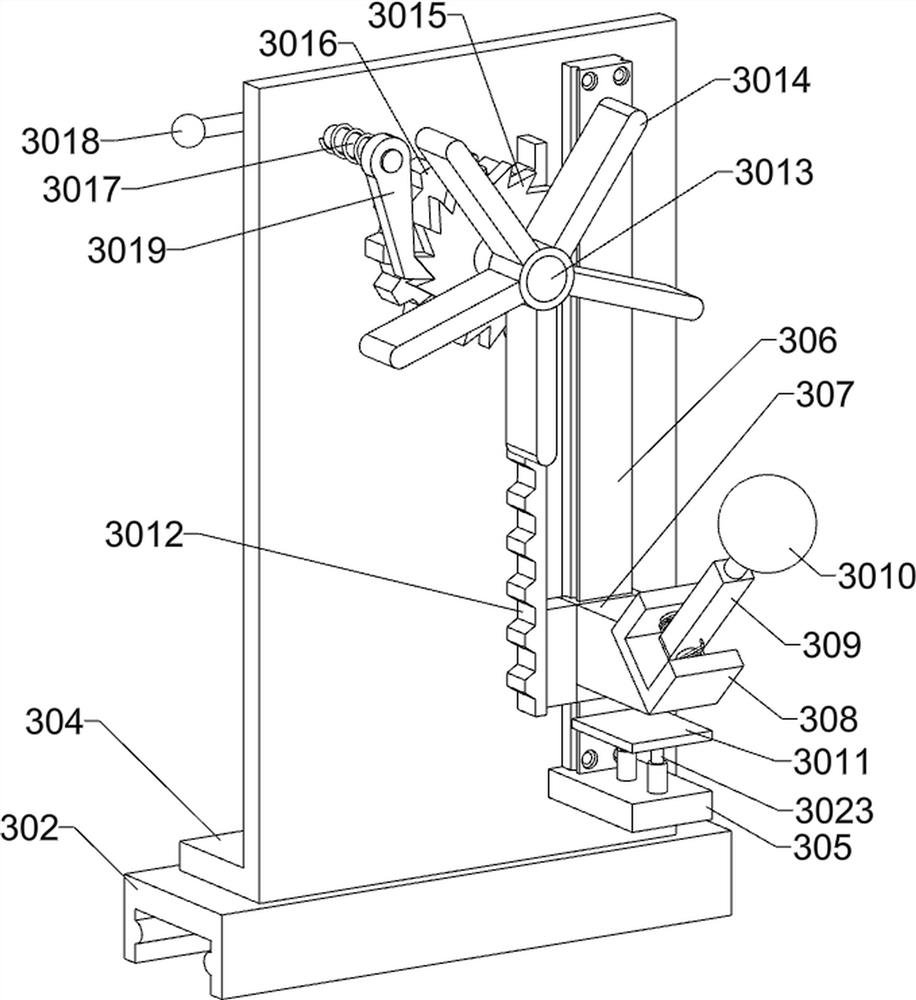

[0031] A paddle performance testing device that simulates the actual use process, such as Figure 1-11 As shown, it includes a foot 1, a first mounting plate 2, a simulated swing unit, a wear-resistant and anti-collision detection unit, and a paddle board anti-bending detection unit; the top of the four feet 1 is connected to the first mounting plate 2; the first The upper right part of the mounting plate 2 is connected with an analog swing unit; the upper middle part of the first mounting plate 2 is connected with a wear-resistant and anti-collision detection unit; the upper side of the first mounting plate 2 is connected with a paddle board anti-bending detection unit.

[0032] According to the present invention, the analog swing unit includes a first mounting frame 201, a second mounting frame 202, a second mounting plate 203, a first rotating shaft 204, a first motor 205, a first transmission shaft 206, and a first connecting rod 207. , universal ball 208, second transmiss...

Embodiment 2

[0043] On the basis of Example 1, such as figure 1 and Figure 12-13 As shown, it also includes a firmness detection unit for the paddle shaft connection; the right part of the upper side of the first mounting plate 2 is connected to the firmness detection unit for the paddle shaft connection, and the firmness detection unit for the paddle shaft connection is located on the paddle plate anti-bending The front of the detection unit; the detection unit for the firmness of the paddle shaft connector includes a seventh mounting frame 501, an eighth mounting plate 502, a second motor 503, a ninth mounting plate 504, a fifth transmission shaft 505, a third connecting rod 506 and The detection board 507; the upper right part of the first installation plate 2 is bolt-connected with the seventh installation frame 501, and the seventh installation frame 501 is located in front of the third electric slide rail 401; the upper part of the seventh installation frame 501 is fixedly connected...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap