Visual inspection machine for coil stock

A detection machine and roll material technology, which is applied to measuring devices, analyzing materials, and analyzing materials through optical means, can solve problems such as low detection efficiency and misjudgment, and achieve improved production efficiency, improved detection efficiency, and maintenance of moving distance consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

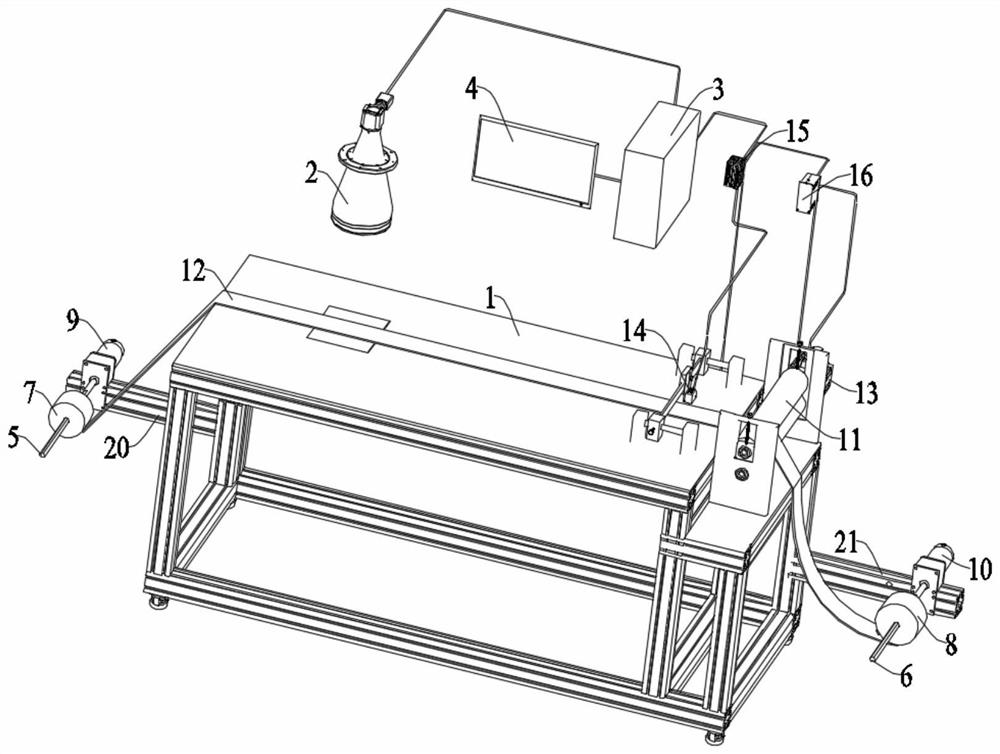

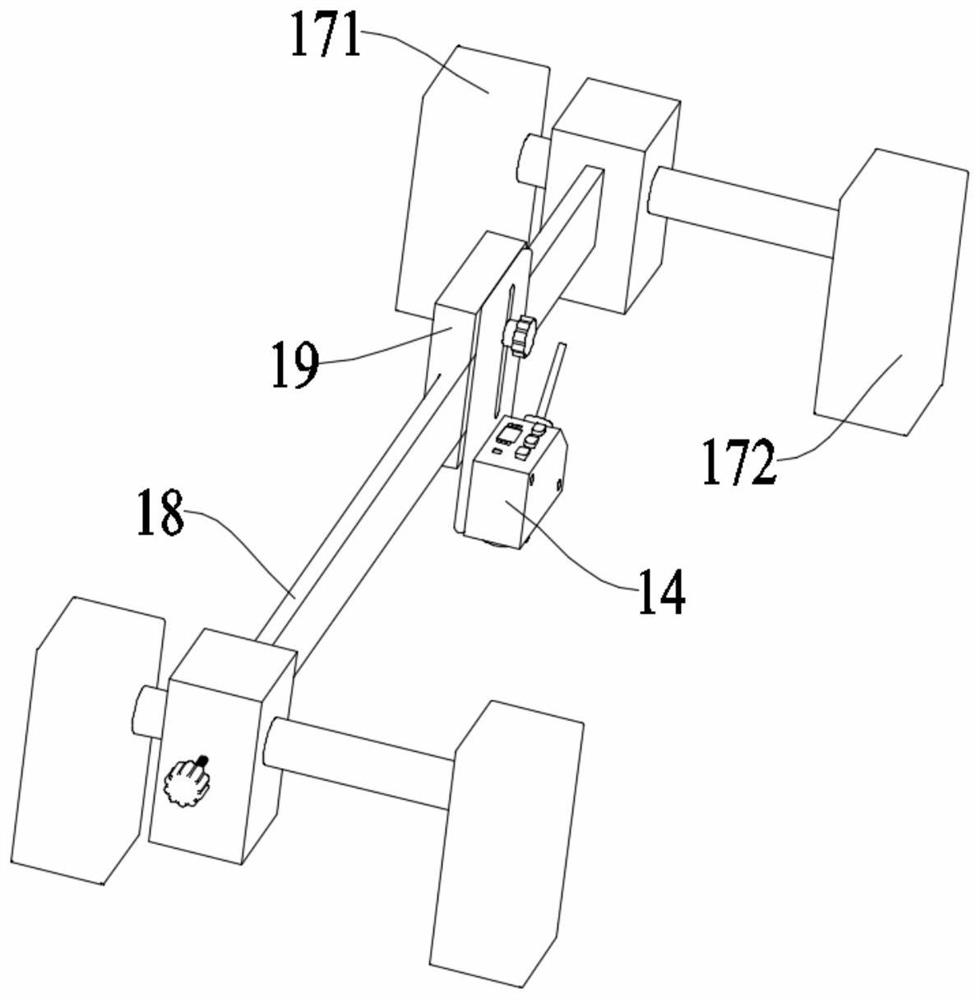

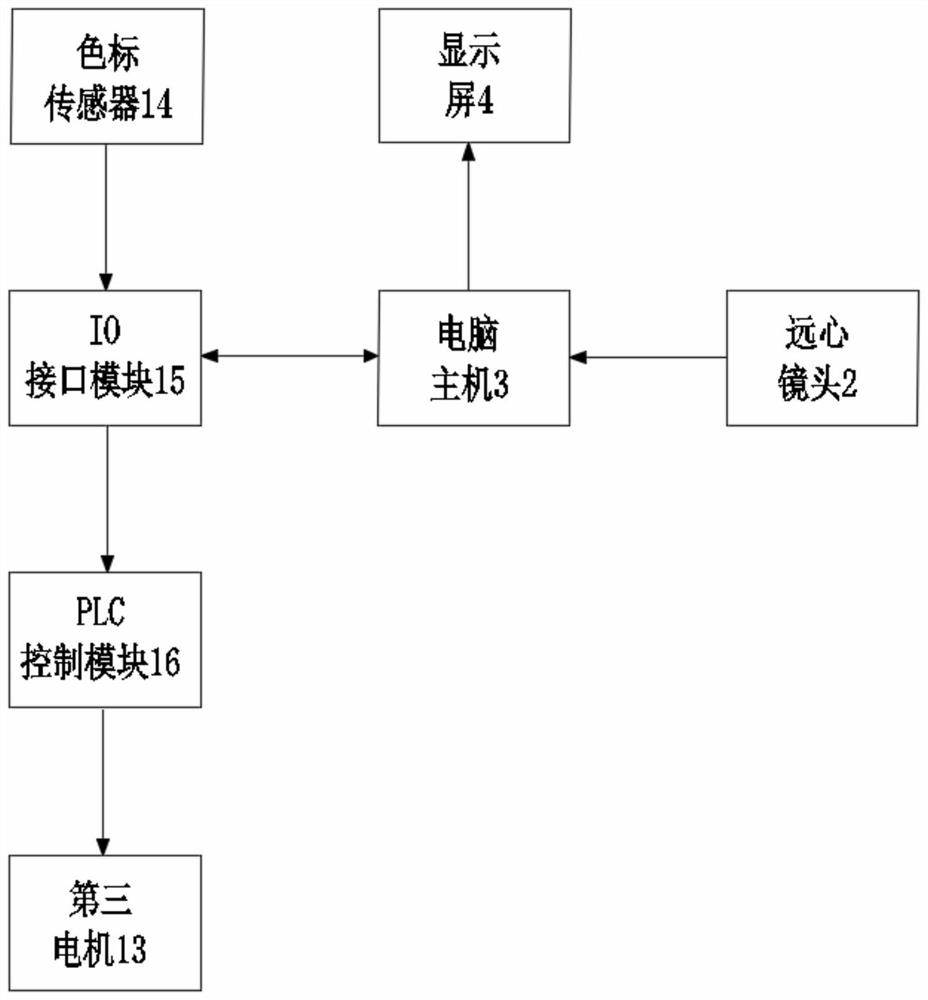

[0022] Embodiment 1: a coil material visual inspection machine, it is characterized in that: described coil material visual inspection machine is used for transfer film coil material belt 12, and this transfer film coil material belt 12 further comprises coil material base belt and several along the length direction The transfer film arranged at intervals on the coil base tape, the coil visual inspection machine includes: a loading platform 1, a telecentric camera 2, a computer host 3, a display screen 4 connected to the computer host 3, respectively located on the loading The feeding shaft 5 and the receiving shaft 6 on both sides of the platform 1, the telecentric camera 2 is located directly above the loading platform 1 and is connected with the computer host 3, and an unwinding reel 7 and a rewinding reel 8 are respectively installed on the discharging On the shaft 5 and the receiving shaft 6, the discharging shaft 5 is arranged on the output shaft of the first motor 9, and...

Embodiment 2

[0028] Embodiment 2: a coil material visual inspection machine, it is characterized in that: described coil material visual inspection machine is used for transfer film coil material belt 12, and this transfer film coil material belt 12 further comprises coil material base belt and several along the length direction The transfer film arranged at intervals on the coil base tape, the coil visual inspection machine includes: a loading platform 1, a telecentric camera 2, a computer host 3, a display screen 4 connected to the computer host 3, respectively located on the loading The feeding shaft 5 and the receiving shaft 6 on both sides of the platform 1, the telecentric camera 2 is located directly above the loading platform 1 and is connected with the computer host 3, and an unwinding reel 7 and a rewinding reel 8 are respectively installed on the discharging On the shaft 5 and the receiving shaft 6, the discharging shaft 5 is arranged on the output shaft of the first motor 9, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap