Polyethylene double-wall corrugated pipe forming equipment

A double-wall corrugated pipe and forming equipment technology, applied in the field of double-wall corrugated pipe production, can solve problems such as damage, difficulty in maintenance and replacement, harsh environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

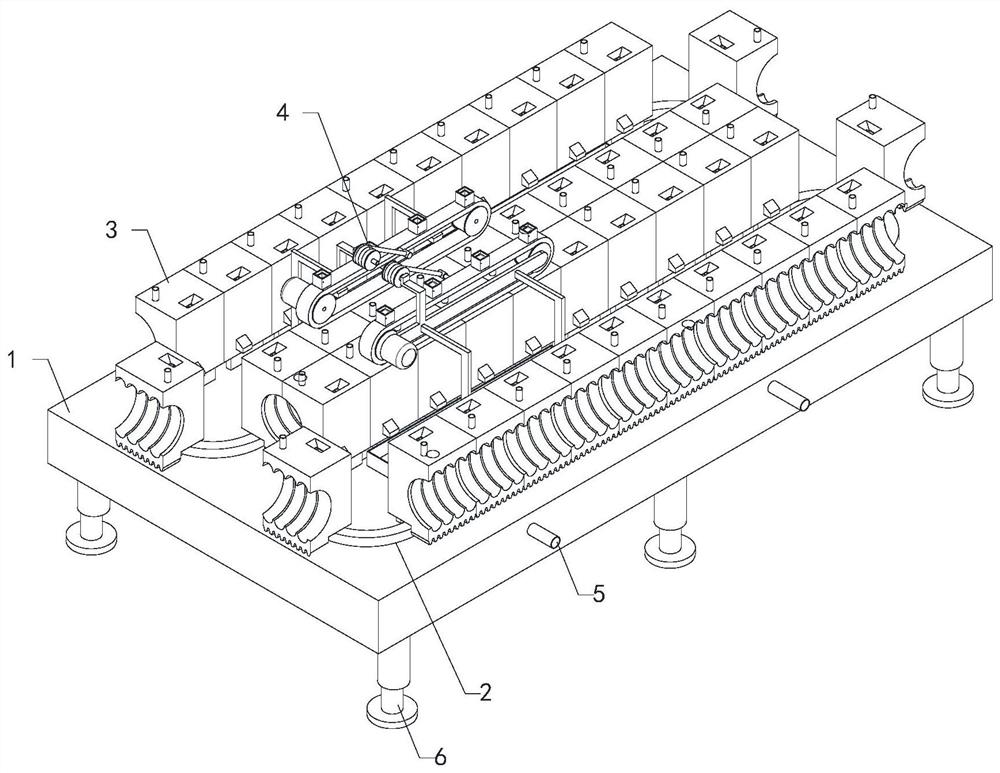

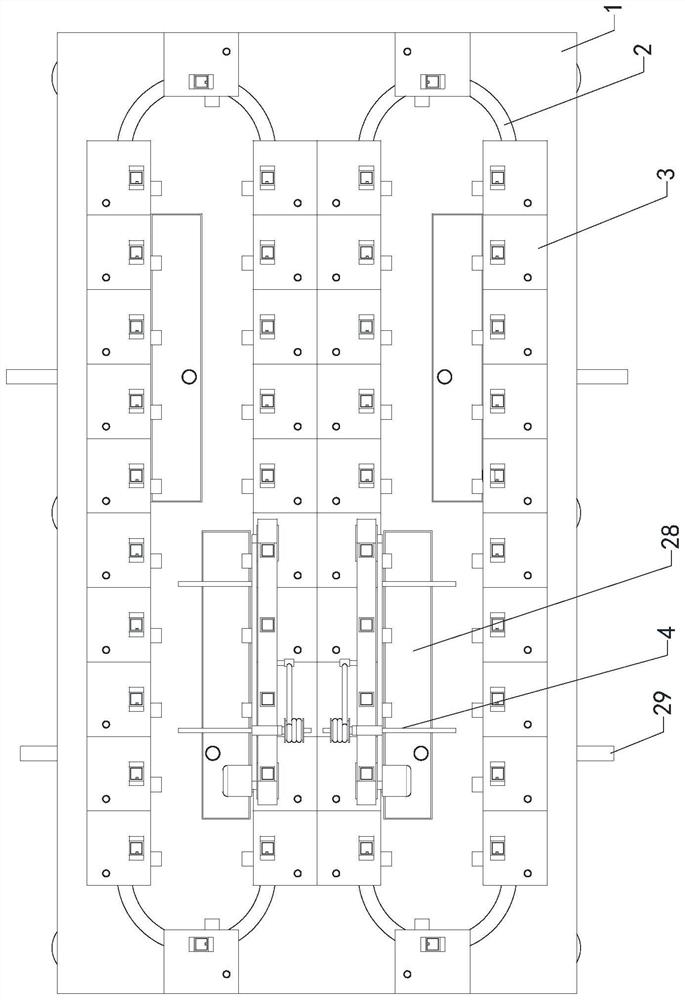

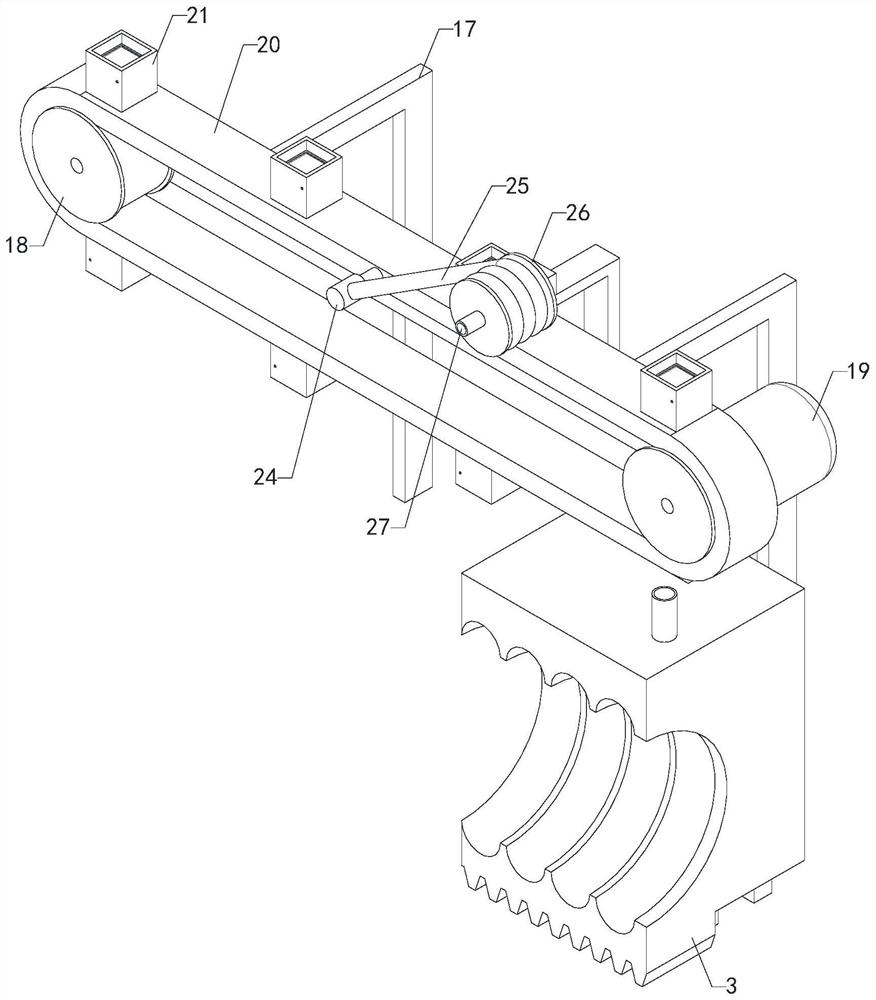

[0022]A polyethylene double-wall corrugated pipe forming equipment, including a platform 1, two slide rails 2, multiple molds 3, two sets of liquid addition systems 4, multiple sets of temperature adjustment systems 5 and multiple legs 6, the upper end of the platform 1 Two ring-shaped slide rails 2 are symmetrically installed on the surface, and multiple molds 3 are respectively symmetrically slid and installed on the two slide rails 2. Multiple molds 3 are closely arranged, and multiple molds 3 are docked and combined at the center line of the platform 1. The molds 3 The front part of the mold is provided with a forming mold, and the inside of the mold 3 is provided with a filling mechanism and a hole-filling pipeline. The bottom of the mold 3 is connected to the driving mechanism on the platform 1. The output mechanism of the liquid feeding system 4 is respectively docked with the filling mechanism of multiple molds 3 on the two slide rails 2, and the multi-group temperature...

Embodiment 2

[0024] A polyethylene double-wall corrugated pipe forming equipment, including a platform 1, two slide rails 2, multiple molds 3, two sets of liquid addition systems 4, multiple sets of temperature adjustment systems 5 and multiple legs 6, the upper end of the platform 1 Two ring-shaped slide rails 2 are symmetrically installed on the surface, and multiple molds 3 are respectively symmetrically slid and installed on the two slide rails 2. Multiple molds 3 are closely arranged, and multiple molds 3 are docked and combined at the center line of the platform 1. The molds 3 The front part of the mold is provided with a forming mold, and the inside of the mold 3 is provided with a filling mechanism and a hole-filling pipeline. The bottom of the mold 3 is connected to the driving mechanism on the platform 1. The output mechanism of the liquid feeding system 4 is respectively docked with the filling mechanism of multiple molds 3 on the two slide rails 2, and the multi-group temperatur...

Embodiment 3

[0026] A polyethylene double-wall corrugated pipe forming equipment, including a platform 1, two slide rails 2, multiple molds 3, two sets of liquid addition systems 4, multiple sets of temperature adjustment systems 5 and multiple legs 6, the upper end of the platform 1 Two ring-shaped slide rails 2 are symmetrically installed on the surface, and multiple molds 3 are respectively symmetrically slid and installed on the two slide rails 2. Multiple molds 3 are closely arranged, and multiple molds 3 are docked and combined at the center line of the platform 1. The molds 3 The front part of the mold is provided with a forming mold, and the inside of the mold 3 is provided with a filling mechanism and a hole-filling pipeline. The bottom of the mold 3 is connected to the driving mechanism on the platform 1. The output mechanism of the liquid feeding system 4 is respectively docked with the filling mechanism of multiple molds 3 on the two slide rails 2, and the multi-group temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com