Refrigerator

A technology of a refrigerator and a refrigerator control method, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of low cooling rate, constant air volume and wind speed, and inability to adjust the air volume and wind speed of the air outlet according to demand. , to achieve the effect of precise air supply control and increase air supply volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

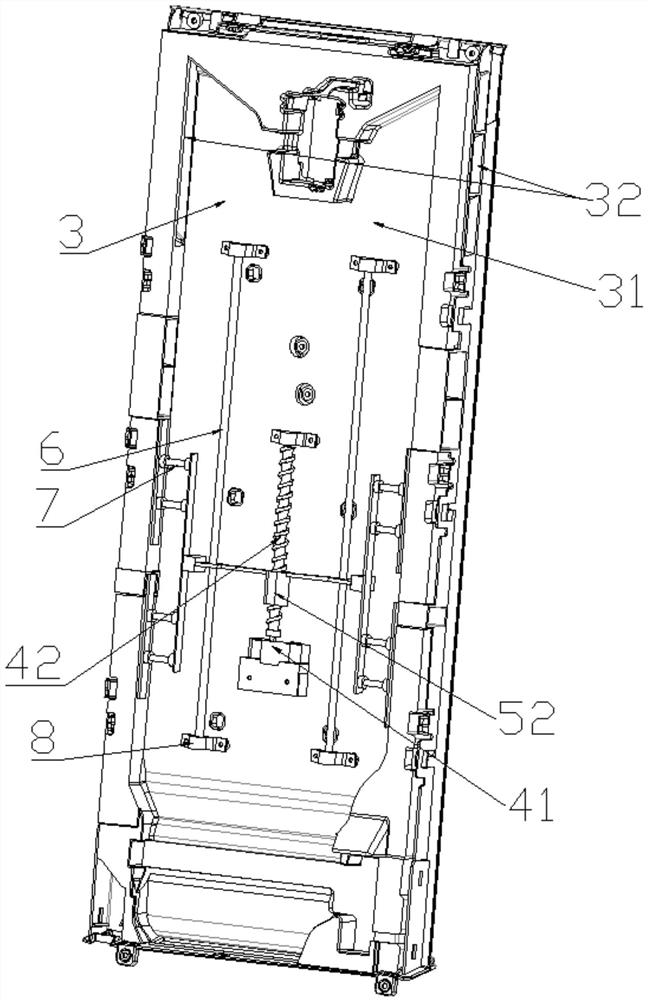

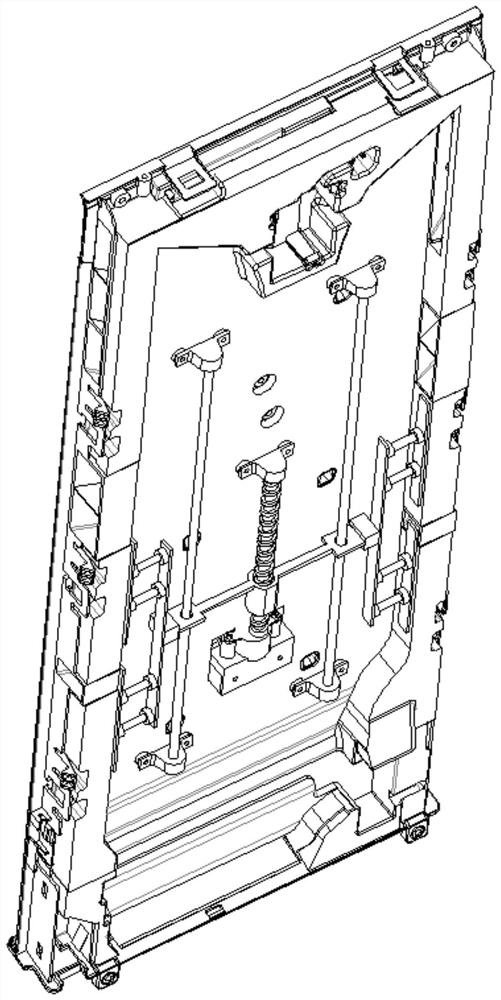

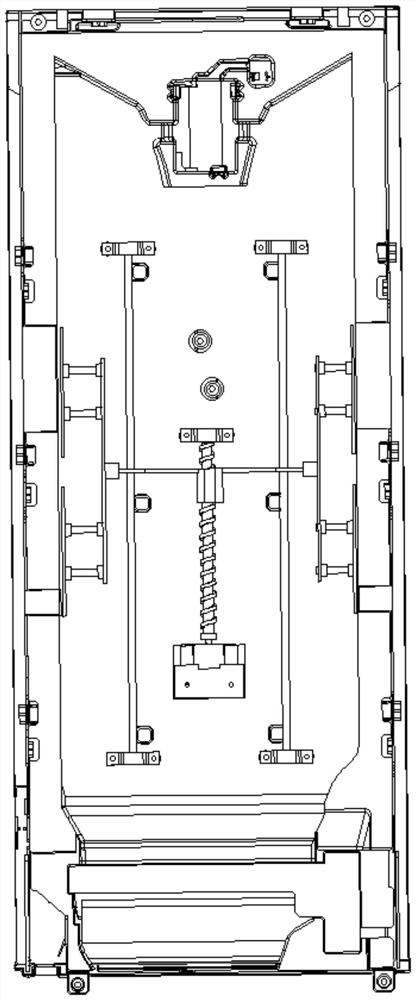

[0086] Such as Figure 1-Figure 9 , a refrigerator, the refrigerator includes a heat-insulated casing, the casing defines a plurality of heat-insulated storage areas for storing items such as food, and the storage areas have openings at their front ends. In the present invention, a refrigerated panel 2 is installed on the side of the housing away from the opening, and a refrigerated foam 3 is installed between the refrigerated panel 2 and the housing. The refrigerated foam 3 and the refrigerated panel 2 are attached and connected. 3 An air cavity 31 is formed on the side away from the refrigerating panel 2. The air cavity 31 is connected with at least two sets of air outlets. The airflow in the air cavity 31 enters the corresponding storage area through the air outlets. The air expansion assembly that expands the area of the air outlet. The air chamber 31 is equipped with a driving assembly and an air duct assembly. The air duct assembly is connected to the driving assembly....

Embodiment 2

[0117] refer to Figure 10-16 Compared with Embodiment 1, this embodiment differs in that the air duct assembly is different. In this embodiment, the air duct assembly includes a deflector plate and a guide plate 53, wherein the deflector plate is set to at least two, and is installed on the air duct assembly. Inside the cavity 31, and set between two groups of air outlets; the guide plate 53, which is installed in the air cavity 31, is connected with the drive assembly through a slider 52, driven by the drive assembly, and the two ends of the guide plate 53 are in contact with the flow guide plate Or separate, to block different positions of the wind chamber 31.

[0118] Specifically, three layers of storage areas are formed inside the casing, which are respectively the first storage area, the second storage area and the third storage area, and the refrigerated foam 3 is correspondingly provided with a first group of air outlets 32 and a second group of air outlets. 33 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com