Wire rod processing device

A technology for processing devices and wires, which is applied to devices for coating liquid on surfaces, manufacturing tools, and arrangement of drying gases, etc., can solve problems such as wire defects and low production and processing efficiency, and achieve short time gaps and increased processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

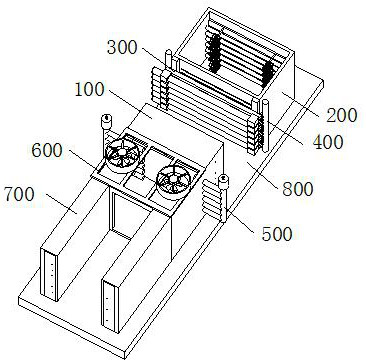

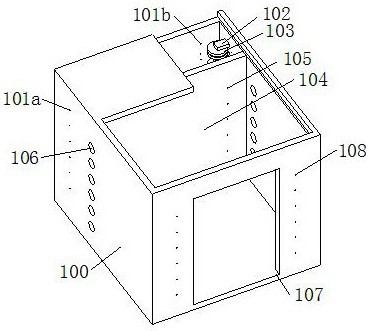

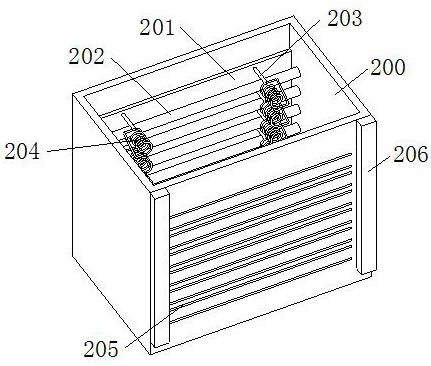

[0033] see Figure 1-8 As shown, the present invention is a wire rod processing device, comprising a box body 100, a heat treatment box 200, a paint delivery pipe 500, a bottom frame 600 and a baking frame 700, the bottom of the heat treatment box 200 is fixed with a bottom plate 800, and in the heat treatment box 200 The metal wires passing through the structure will be induction heated, the bottom plate 800 will support the present invention on the ground, and the side of the box body 100 close to the heat treatment box 200 is fixed with a partition 104, and the partition 104 will connect the transmission lines in the box body 100. The disc 103 is separated from the absorption block 504, and the heat treatment box 200 is connected with a connecting rod 203 through a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com