Method for testing compression watertight performance of foam

A water-tight and high-performance technology, used in measurement devices, suspension and porous material analysis, scientific instruments, etc., can solve the problem that it cannot be close to the working conditions of vehicles, the water-tight performance check standard is loose, and it cannot match the foam water-tight performance check standard. and other problems, to achieve the effect of reducing the probability of changes and after-sales problems, strong durability and performance discrimination, and good matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

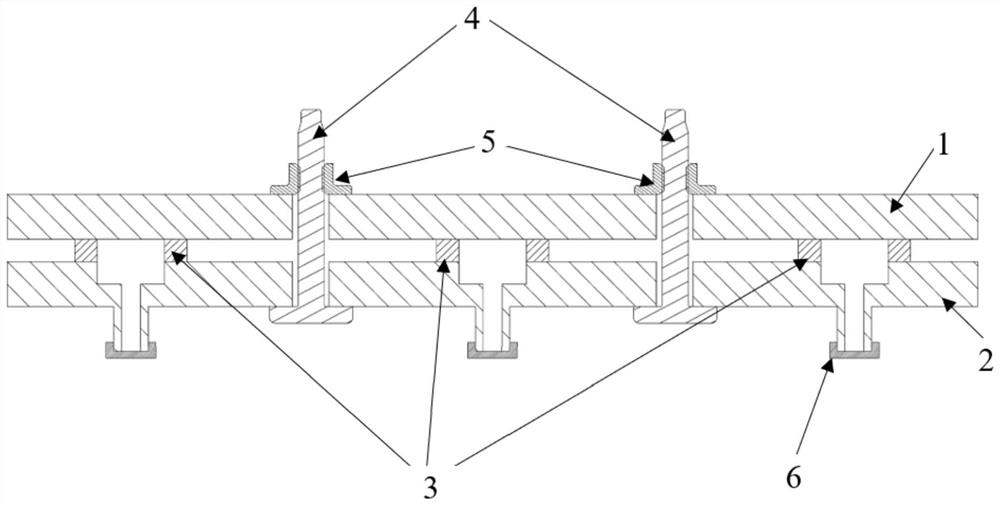

[0084] use as figure 1 The shown watertight performance test tool follows the steps below to test the watertight performance of foam compression:

[0085] (1) Take the foam sample, first install the foam sample on the watertight performance test tool for compression, the compression amount is 50%, and then store the foam sample installed on the watertight performance test tool at high temperature in the compressed state treatment, salt spray durability treatment and high and low temperature shock cycle treatment, and cycled 3 times; among them,

[0086] In the high-temperature storage process, it is stored in an environment of 70 ° C for 72 hours;

[0087] In the salt spray durable treatment, it is stored for 24 hours according to the method of GMW 3286;

[0088] In the high and low temperature shock cycle treatment, first store at 40°C for 7 hours, then store at 38°C and 95% humidity for 17 hours, then store at 70°C for 7 hours, and then store at 38°C and 95% humidity Stor...

Embodiment 2

[0102] The difference with embodiment 1 is only: in step (1),

[0103] In the high-temperature storage process, it is stored in an environment of 80 ° C for 76 hours;

[0104] In the salt spray durable treatment, it is stored for 26 hours according to the method of GMW 3286;

[0105] In the high and low temperature shock cycle treatment, first store at 30°C for 10 hours, then store at 30°C and 97% humidity for 19 hours, then store at 60°C for 10 hours, and then store at 35°C and 99% humidity Stored for 36 hours, a total of 75 hours;

[0106] The total duration of three cycles of high temperature storage treatment, salt spray durability treatment and high and low temperature shock cycle treatment is 531h.

Embodiment 3

[0108] The difference with embodiment 1 is only: in step (2),

[0109] The test position of the foam sample is located at 10cm underwater;

[0110] The inflated CO is 4Kpa, and the inflation time lasts 45s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com