Molding unit with magnetic bistable device

A technology of moulding, mold base, applied in the field of molding units with magnetic bistable devices, able to solve the problem of being out of service for several hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

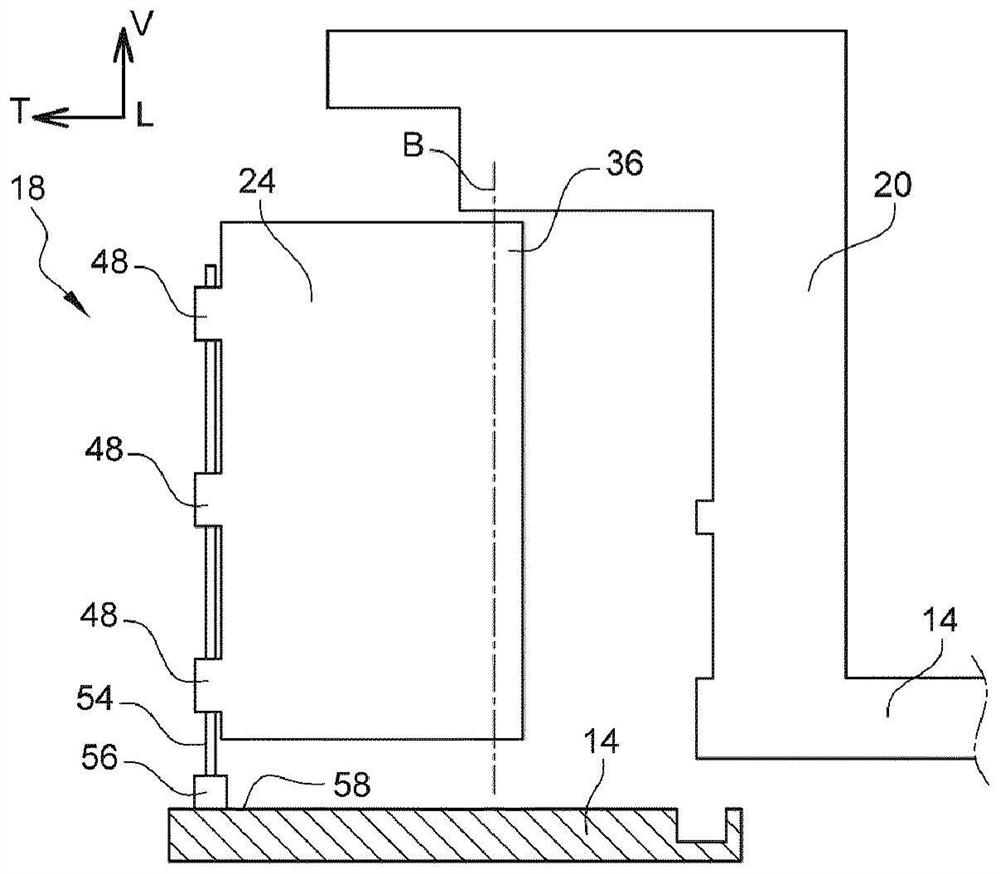

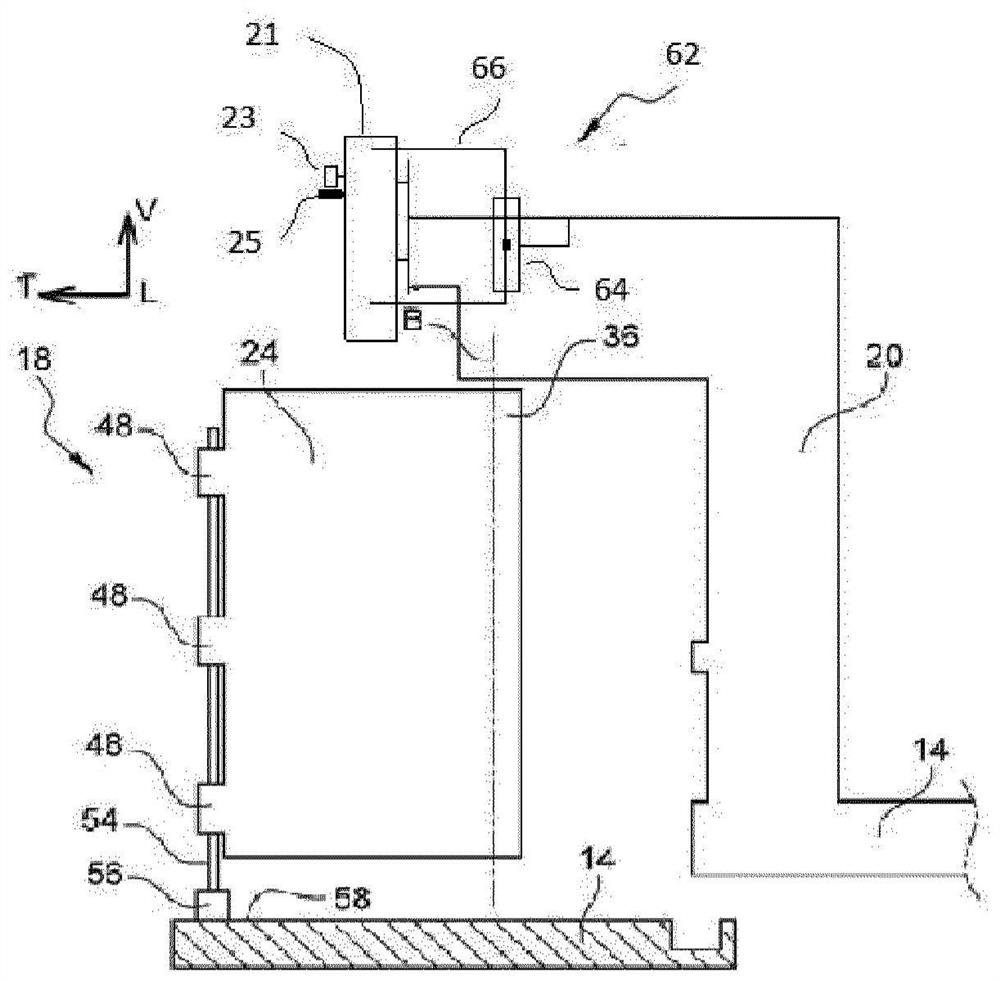

[0072] In the following description, components having the same structure or similar functions will be denoted by the same reference numerals.

[0073] In the following, the following directions will be adopted as local geometric coordinates for each molding unit without limitation:

[0074] - longitudinal direction L, oriented from rear to front orthogonally to the mold joint faces in joint position;

[0075] - vertical direction V, oriented from bottom to top parallel to the hinge axis of the die base;

[0076] - Transverse direction T, oriented from left to right parallel to the joint face of the mold in joint position.

[0077] figure 1 A forming station 10 for forming containers of thermoplastic material, especially PET (polyethylene terephthalate) containers, by blowing hot preforms is schematically shown in . The forming station 10 is intended to be an integral part of a high-volume container manufacturing plant. A plant of this type has, for example, a cold preform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com