Cotton packaging film winding device with automatic feeding function

An automatic feeding and winding device technology, which is applied in the directions of transportation and packaging, thin material handling, winding strips, etc., can solve problems such as low work efficiency, reduced winding efficiency, and increased labor costs, and achieves simple structure, The effect of saving labor costs and improving winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

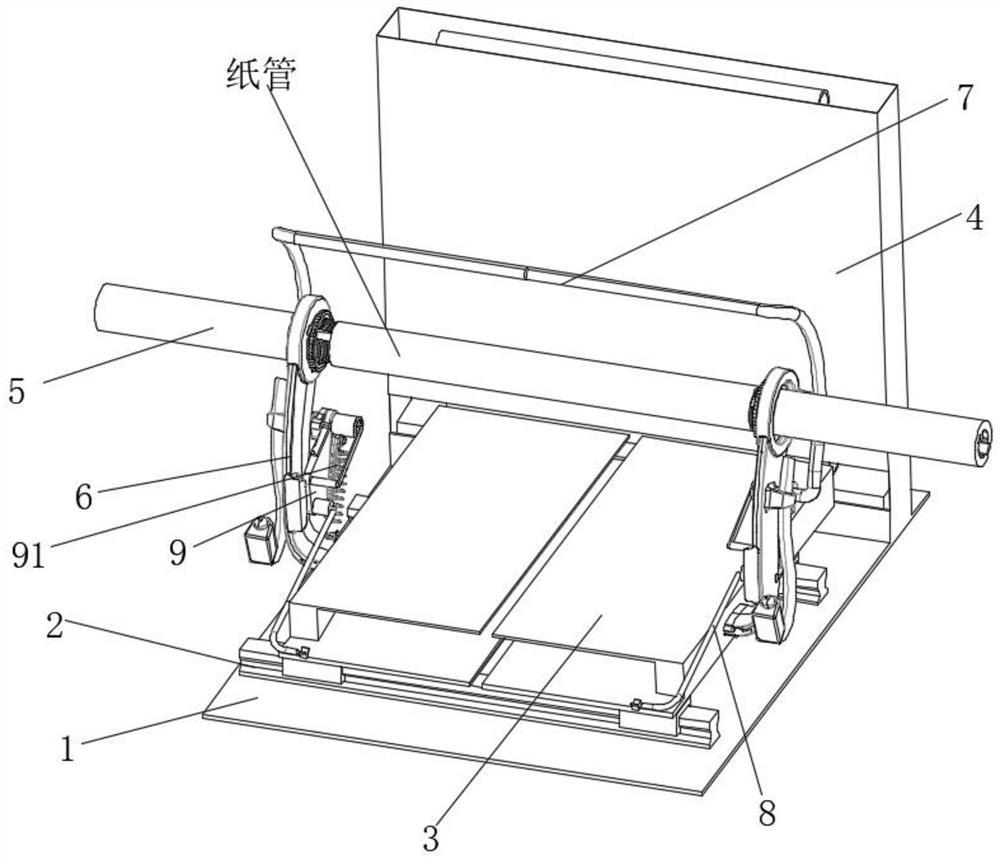

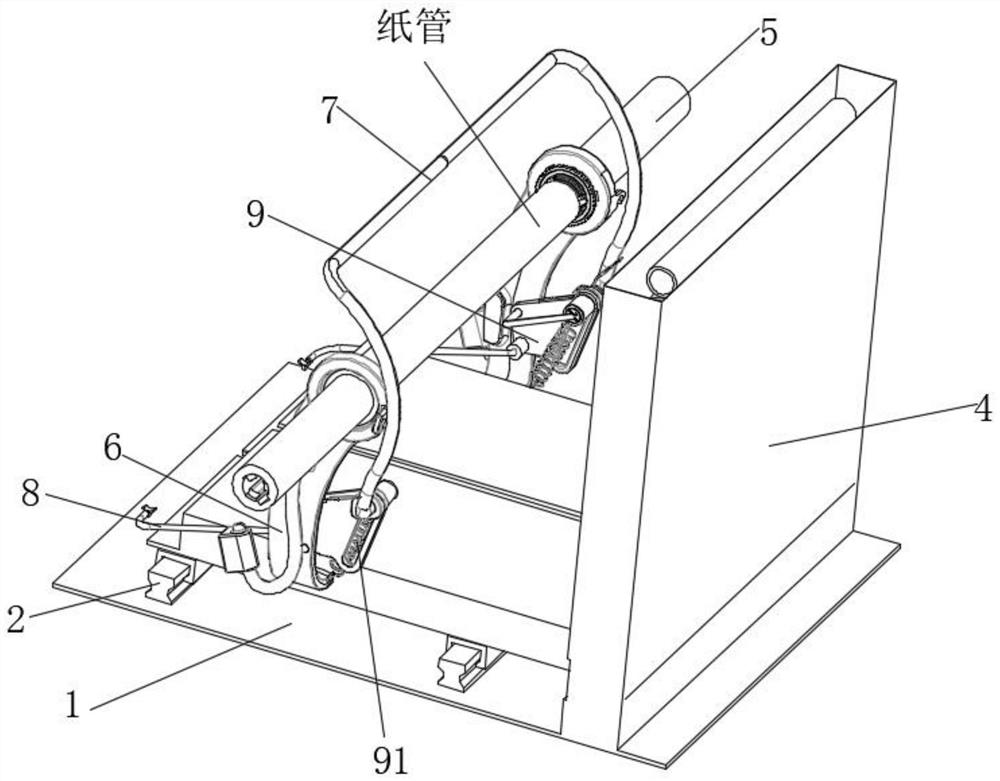

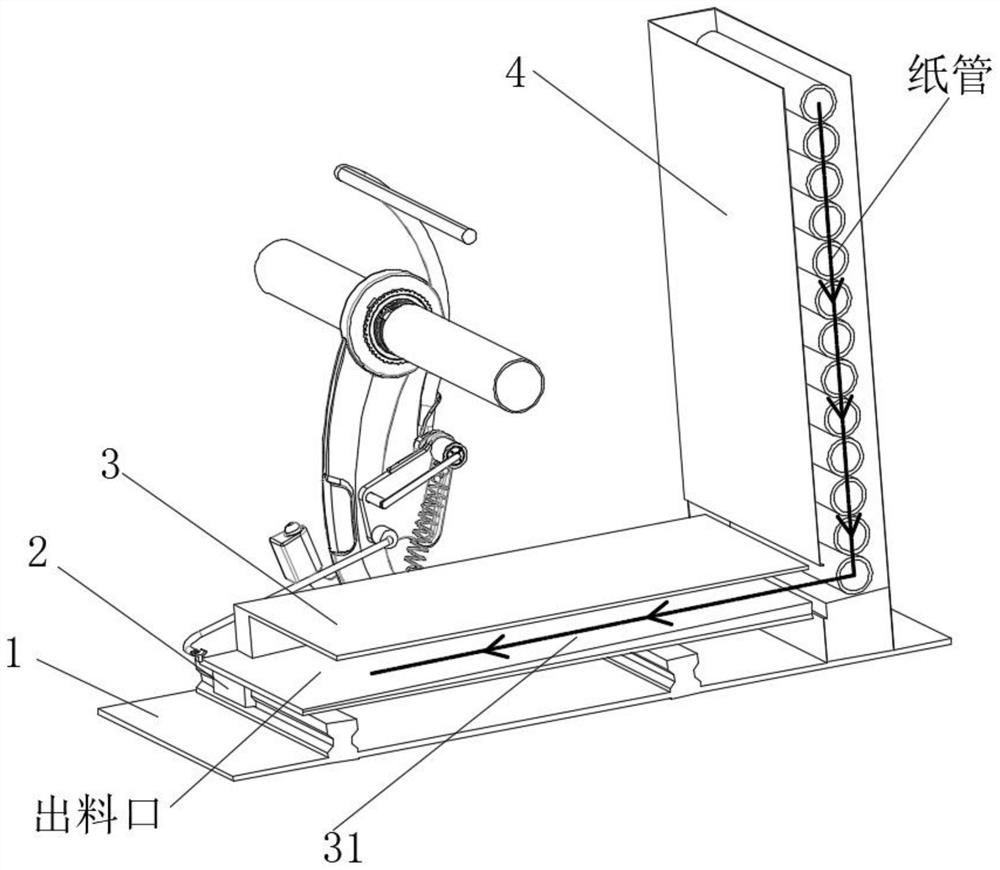

[0042] see Figure 1-10 , a cotton baling film winding device with automatic feeding function, including a bottom plate 1 and a driving roller 5, the top of the bottom plate 1 is slidingly connected with two sets of symmetrically arranged guide bins 3 through a linear module 2, two guide bins 3 The side far away from each other is fixed with a support 6, and the drive roller 5 is connected to the top of the support 6 through a bearing structure. A threaded post 961 is screwed into the sleeve 94, and one side of the fixed cover 94 is connected with a discharge rod 7 through a bearing structure. One end of the discharge rod 7 is provided with a spline groove 71, and one end of the threaded post 961 is screwed into A spline shaft 96 matching the spline groove 71 is fixed on one side, and a first tension spring 95 is sandwiched between the spline shaft 96 and the fixed sleeve 94, and the other side of the fixed sleeve 94 is connected with an adjusting stud 99 through a threaded st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com