Patents

Literature

34results about How to "Convenient loading operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

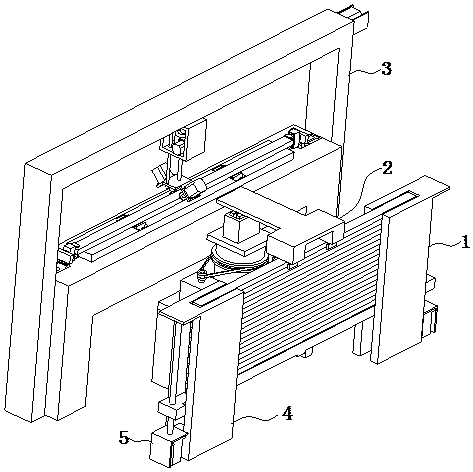

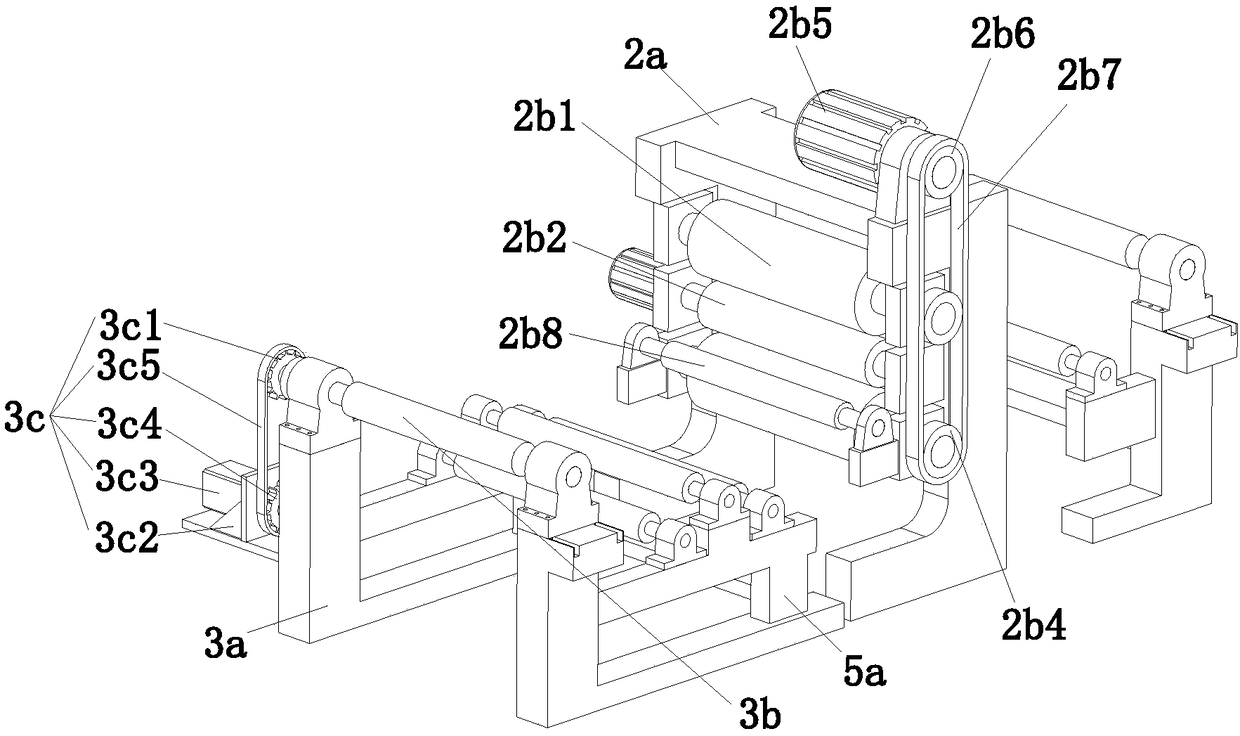

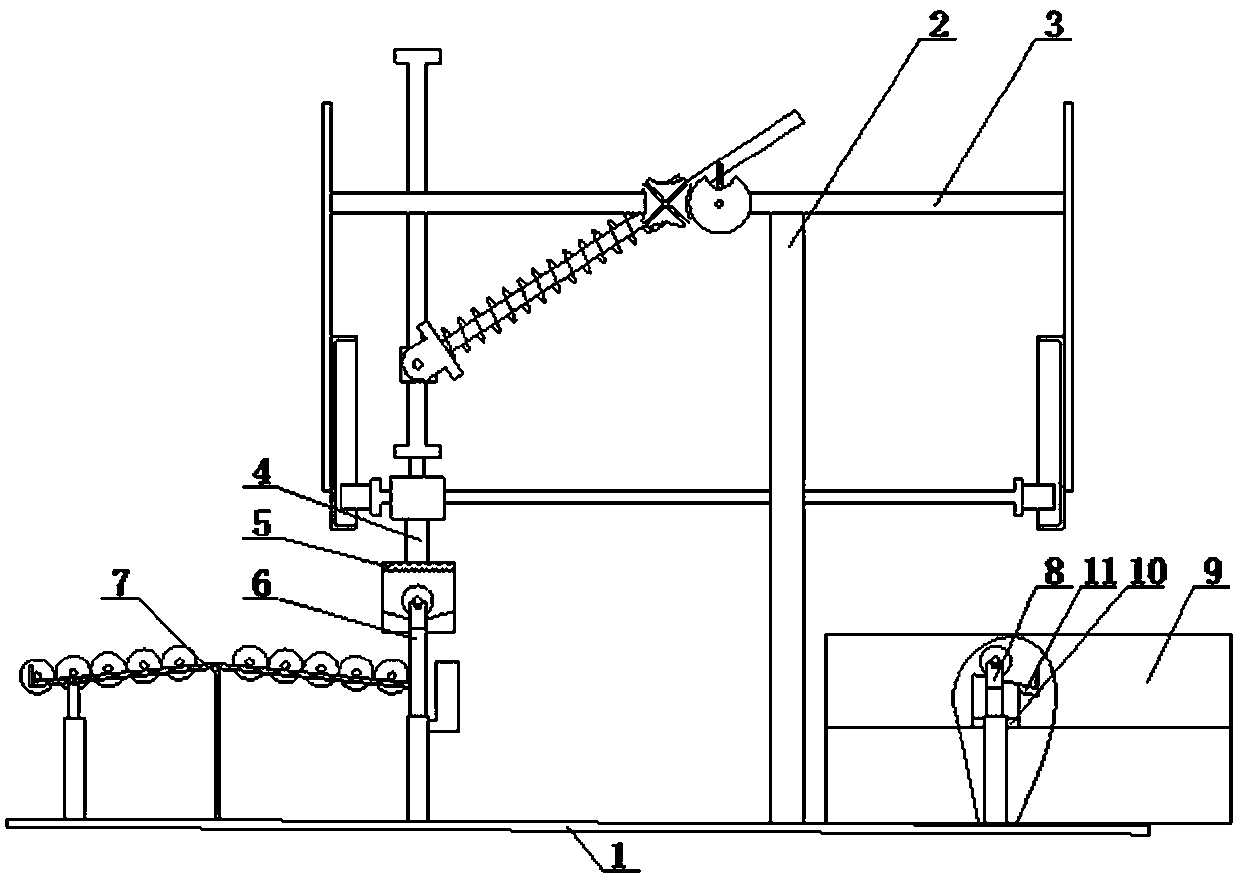

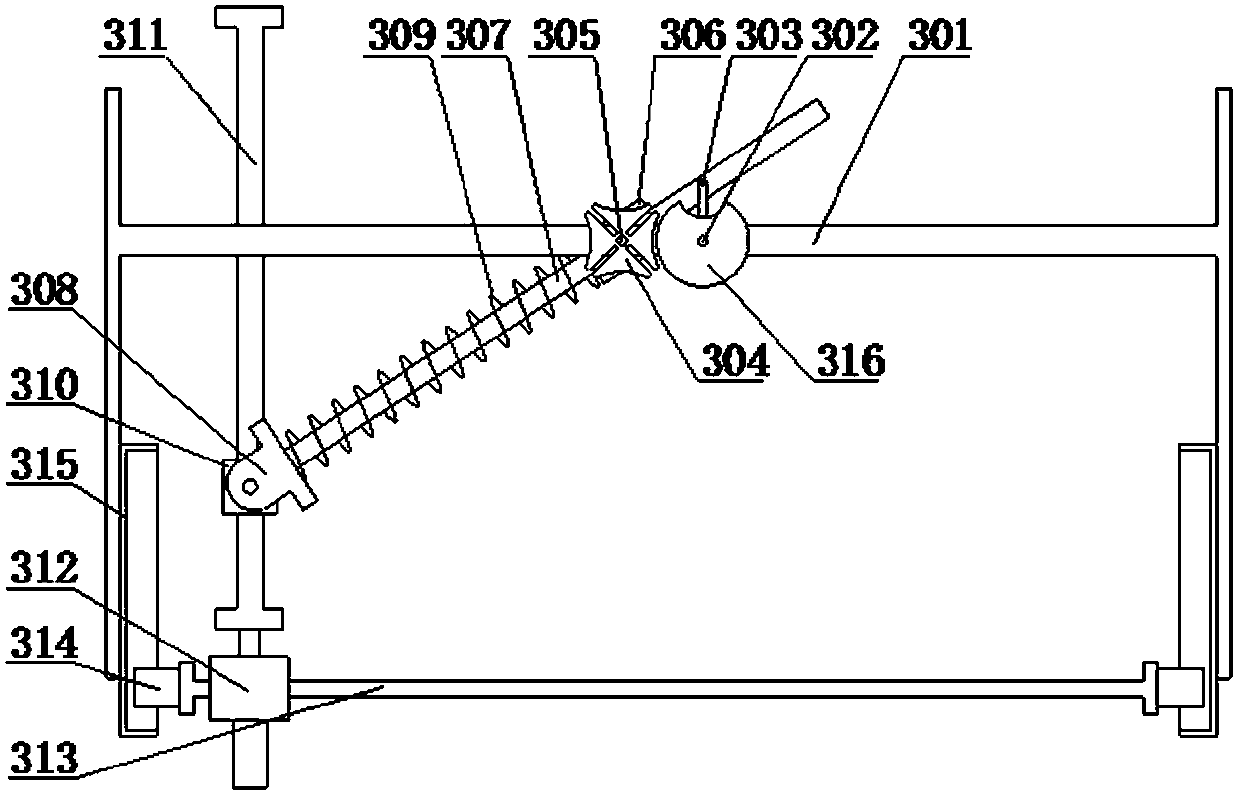

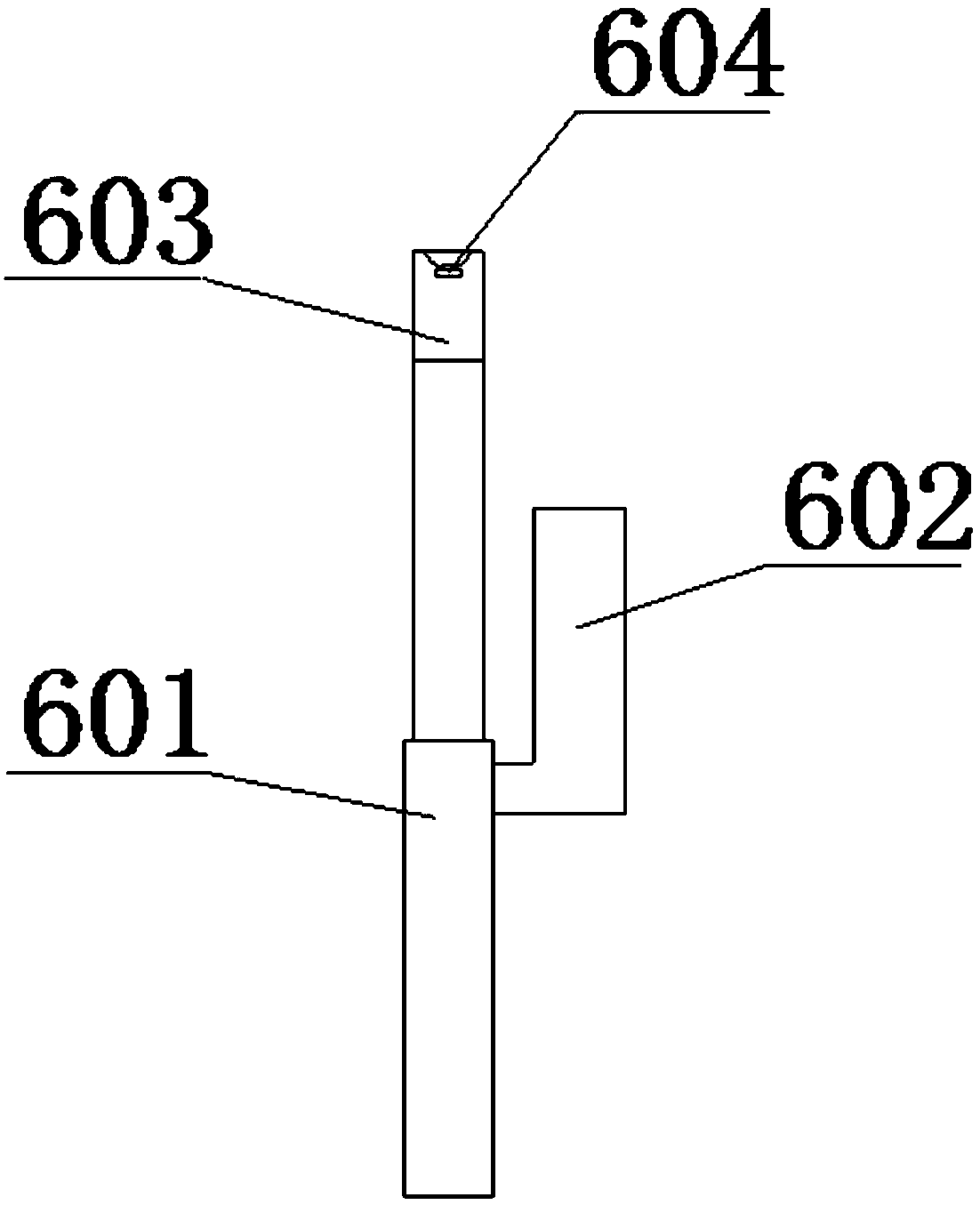

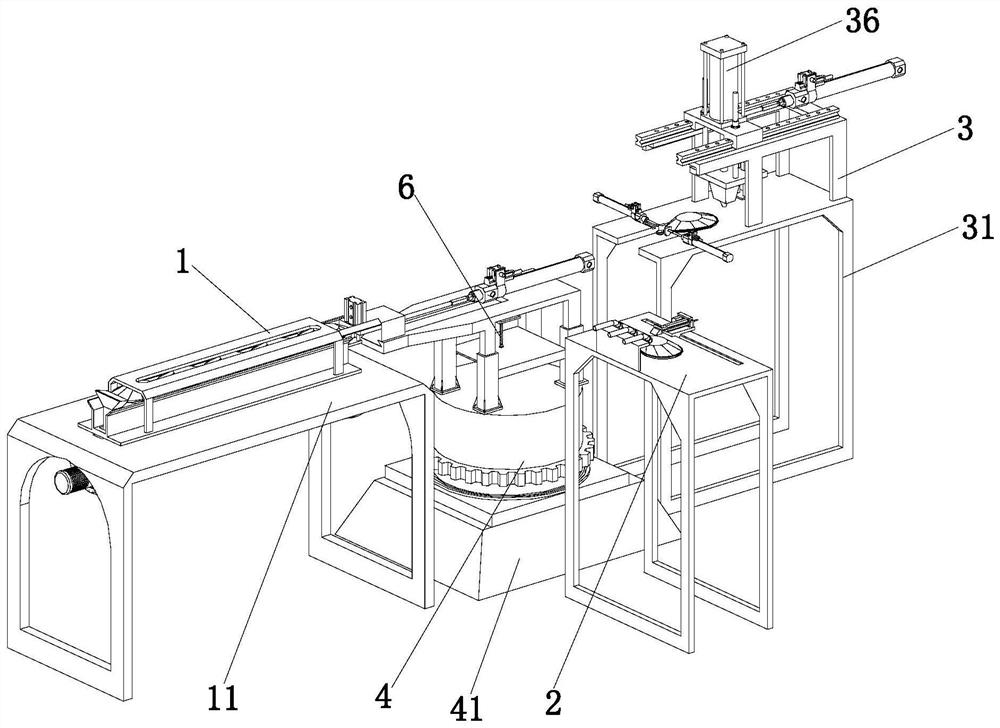

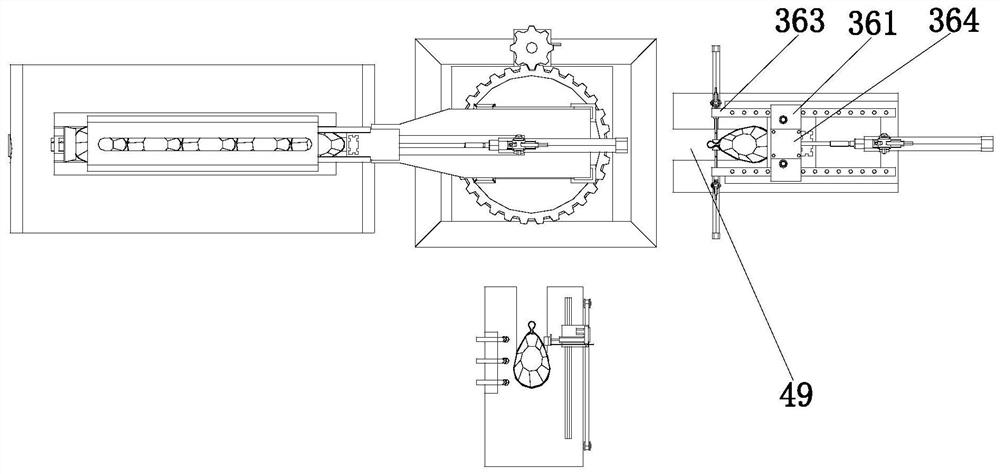

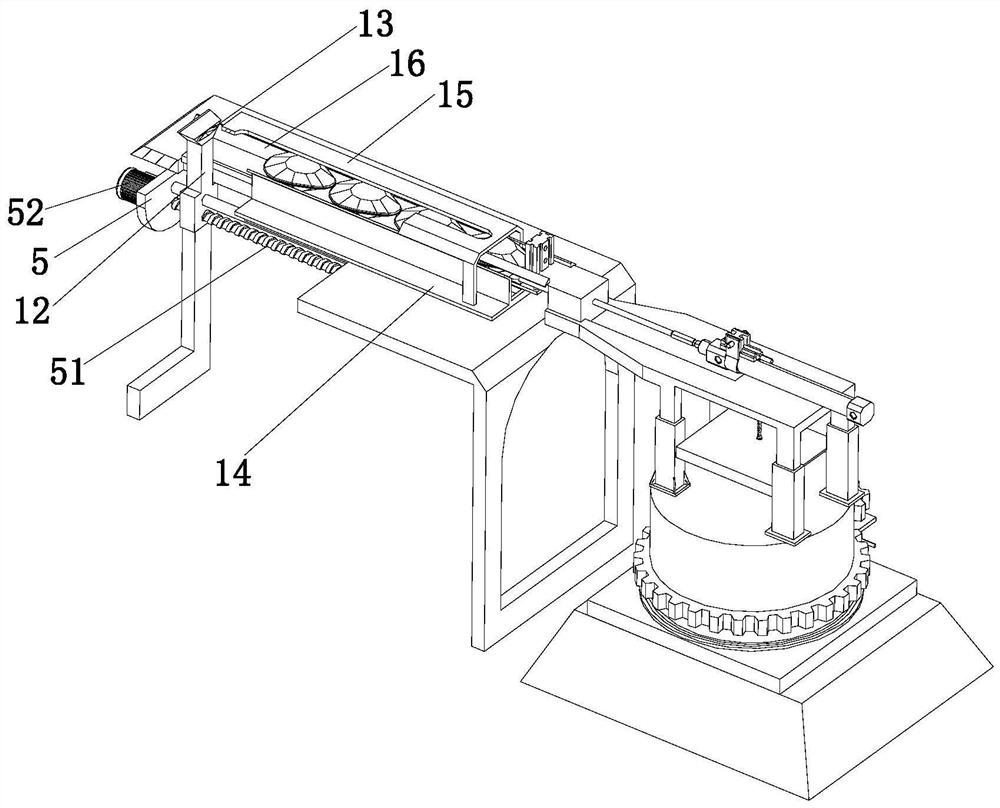

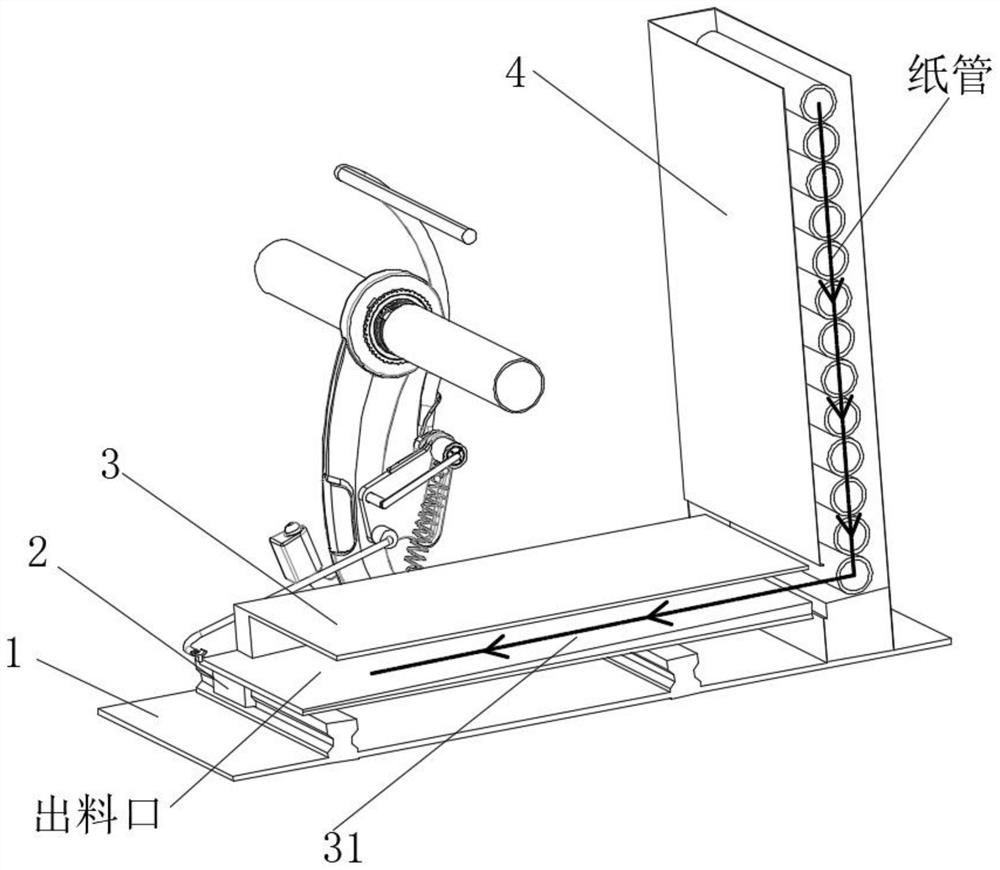

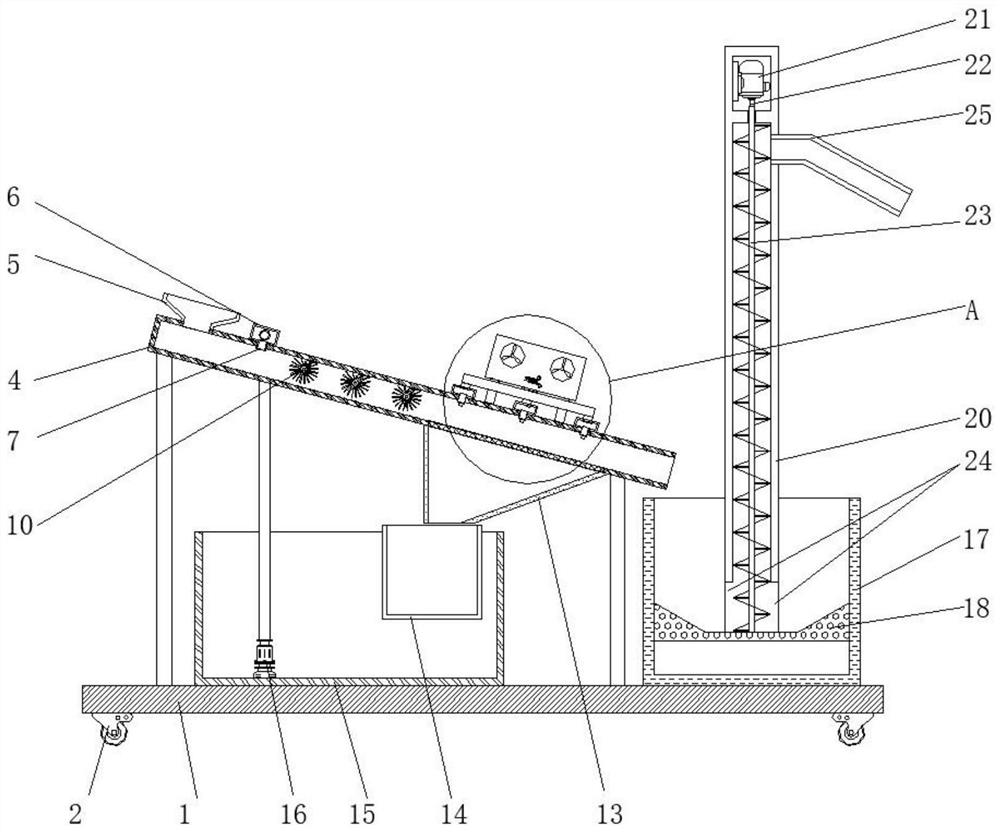

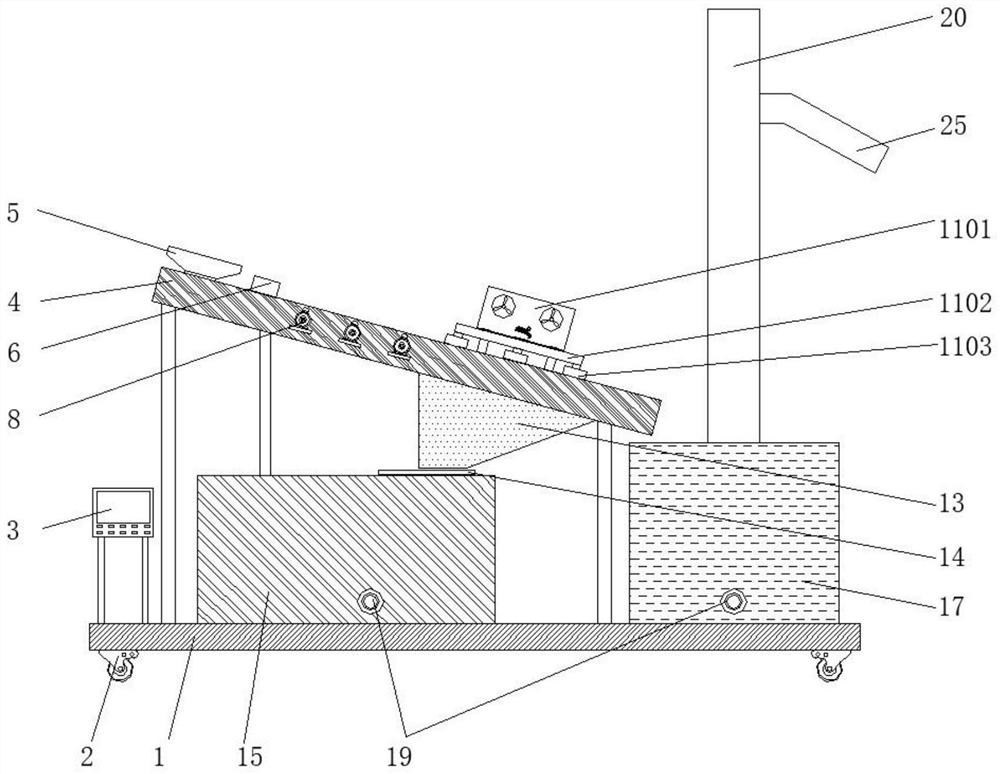

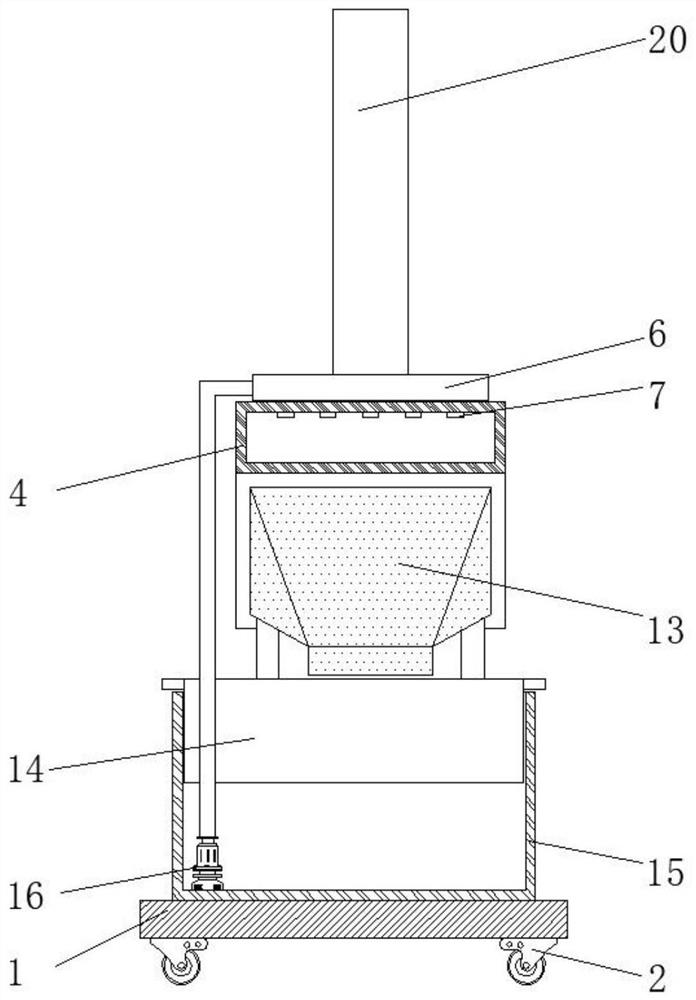

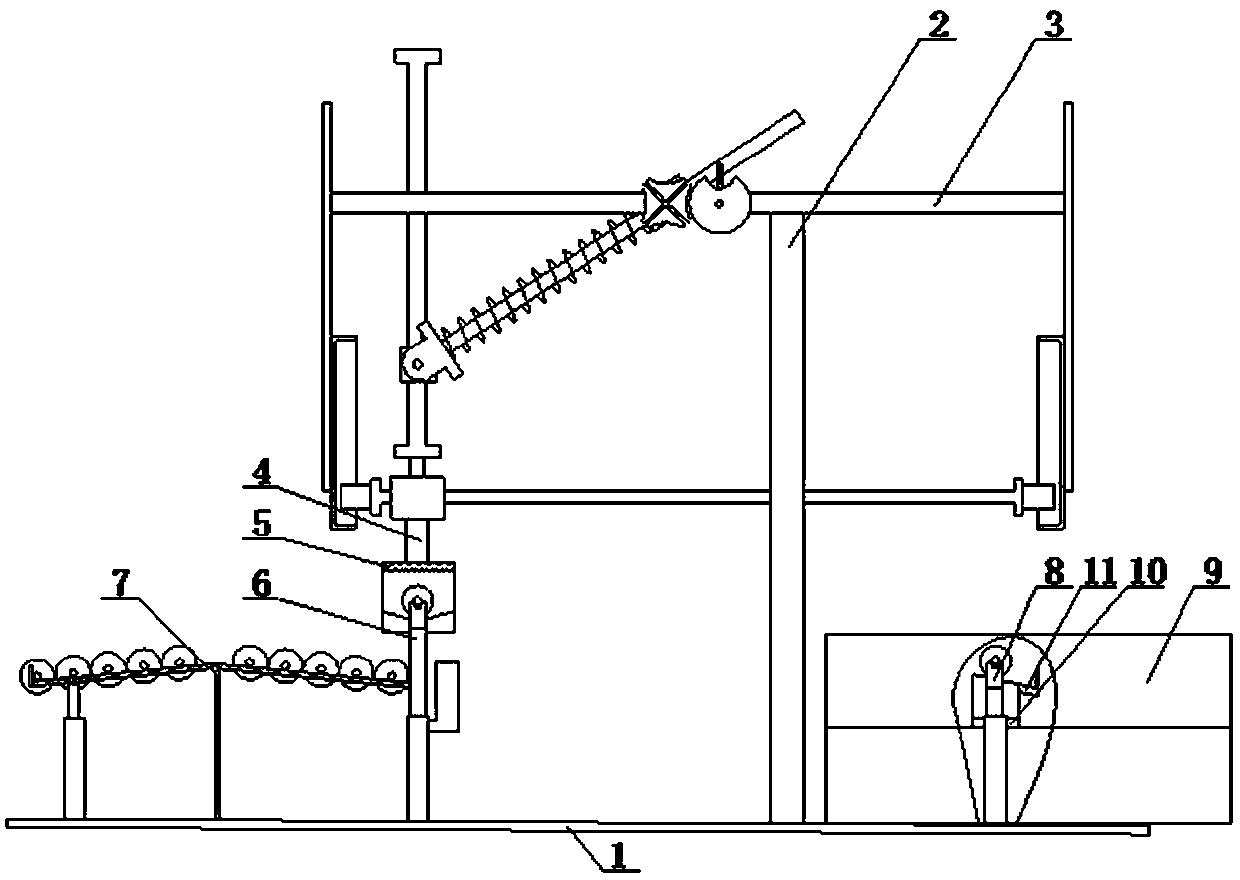

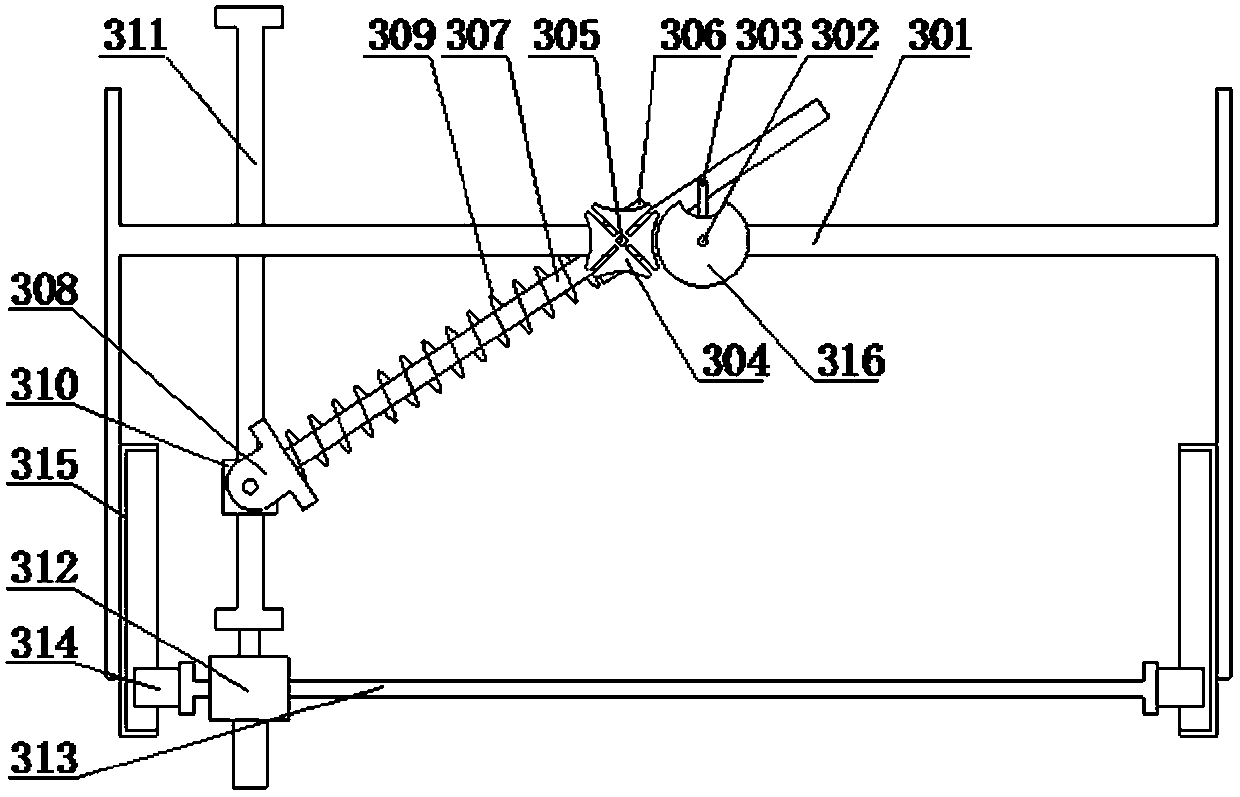

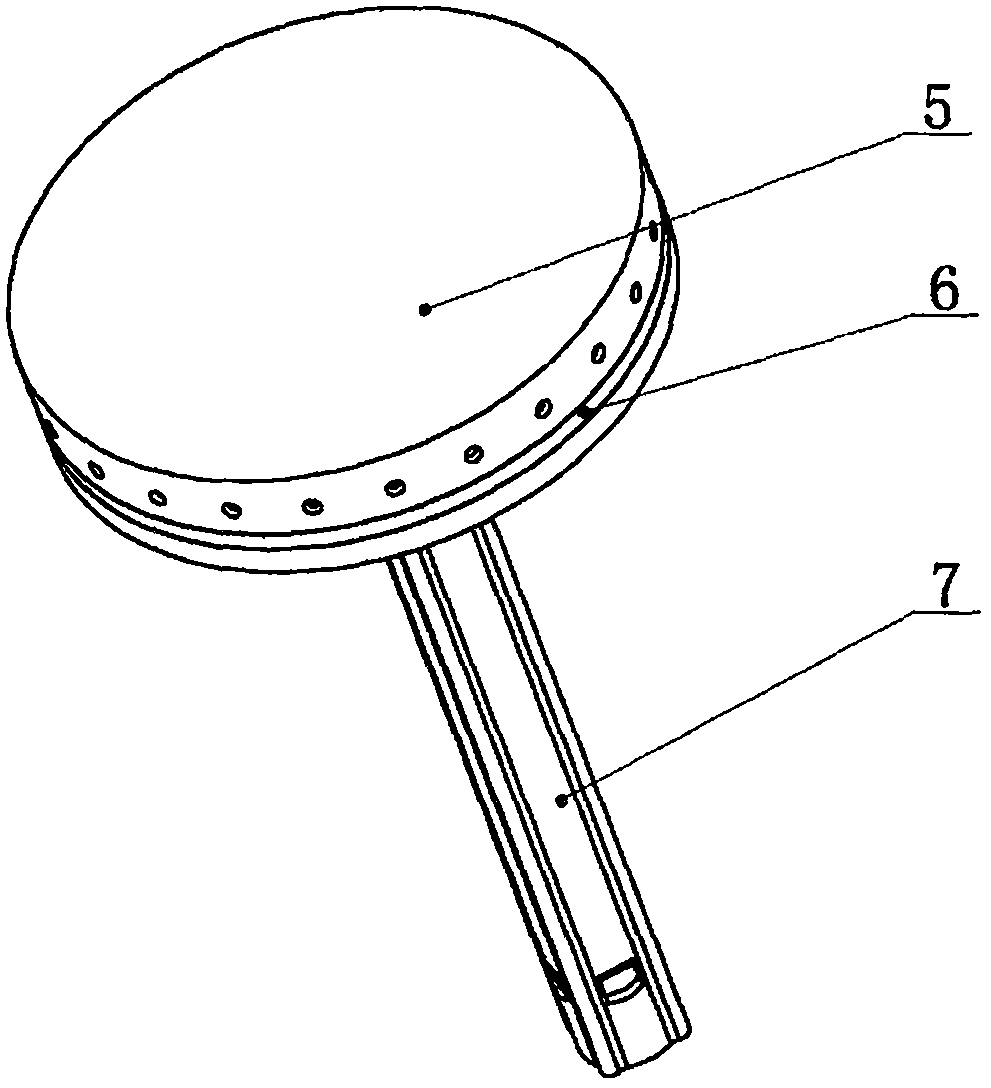

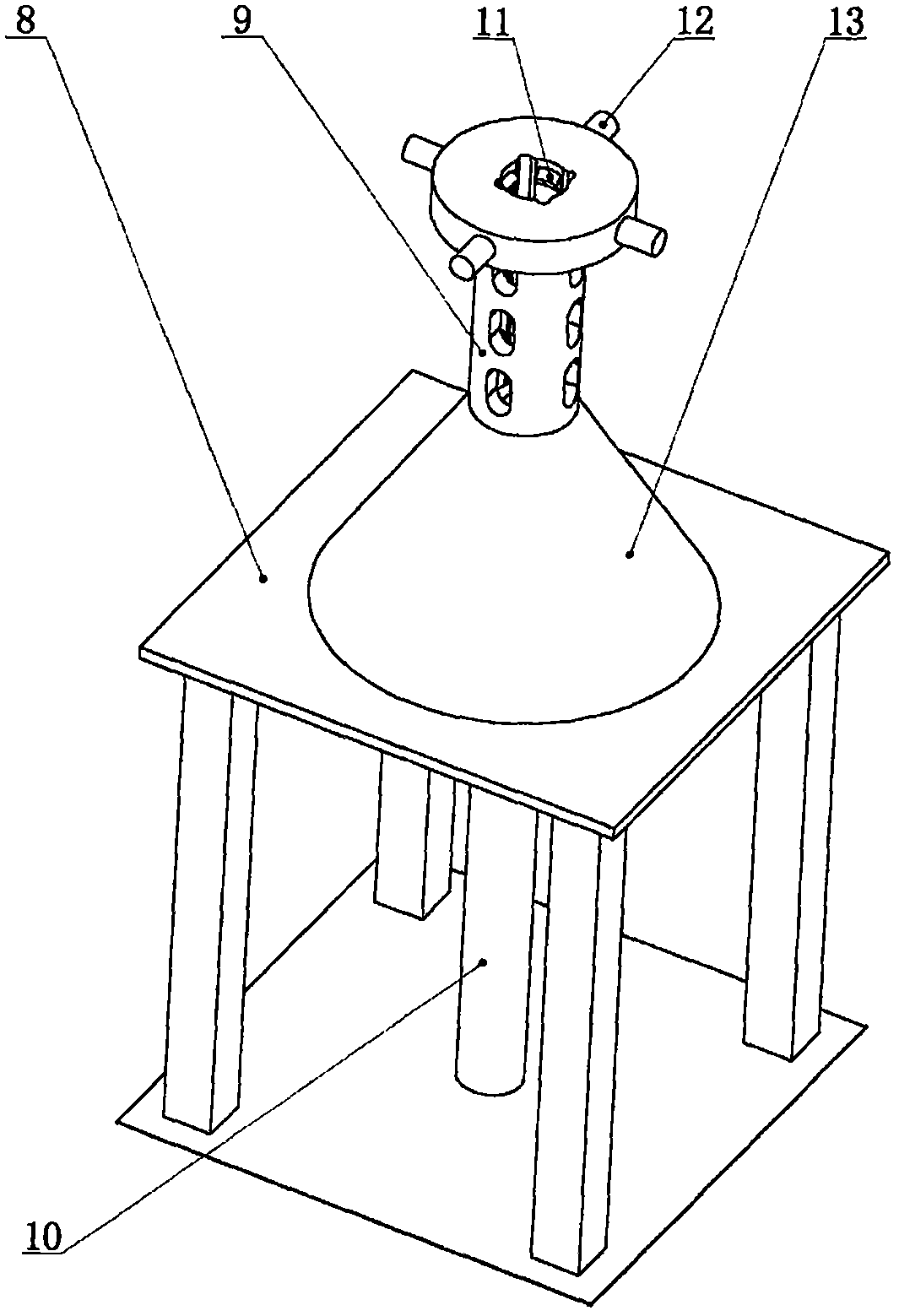

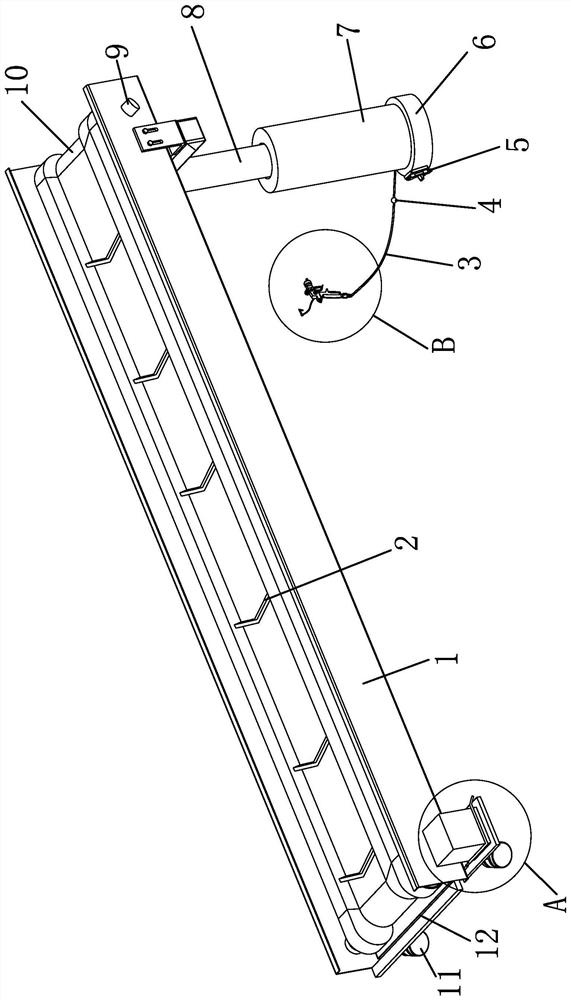

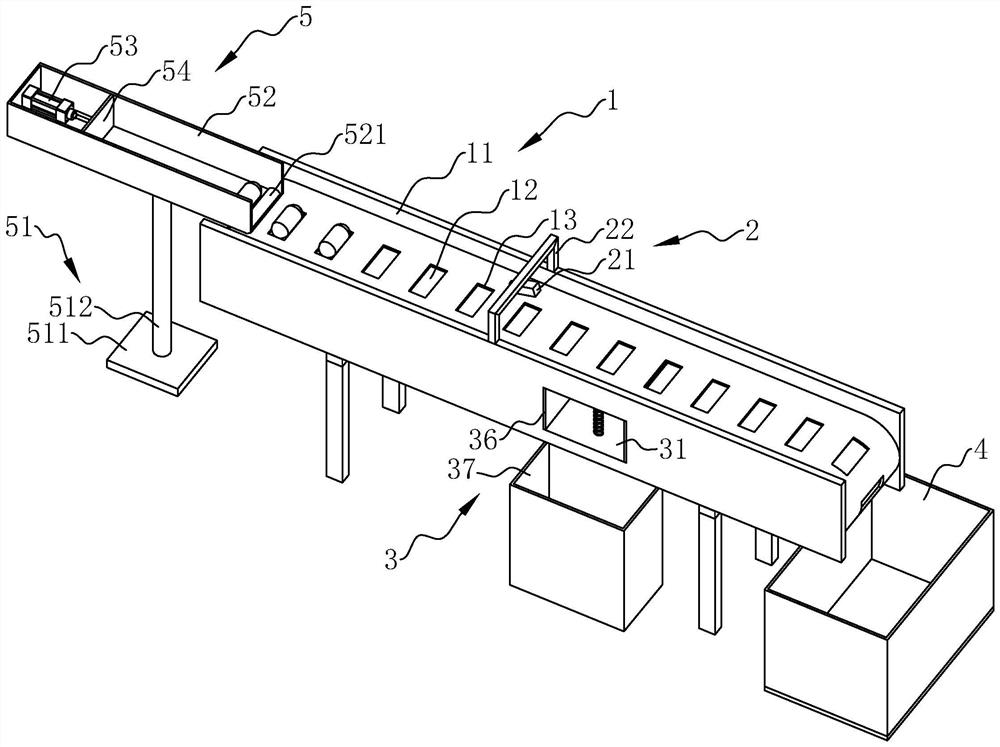

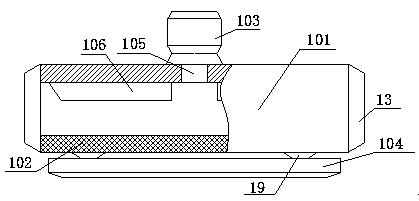

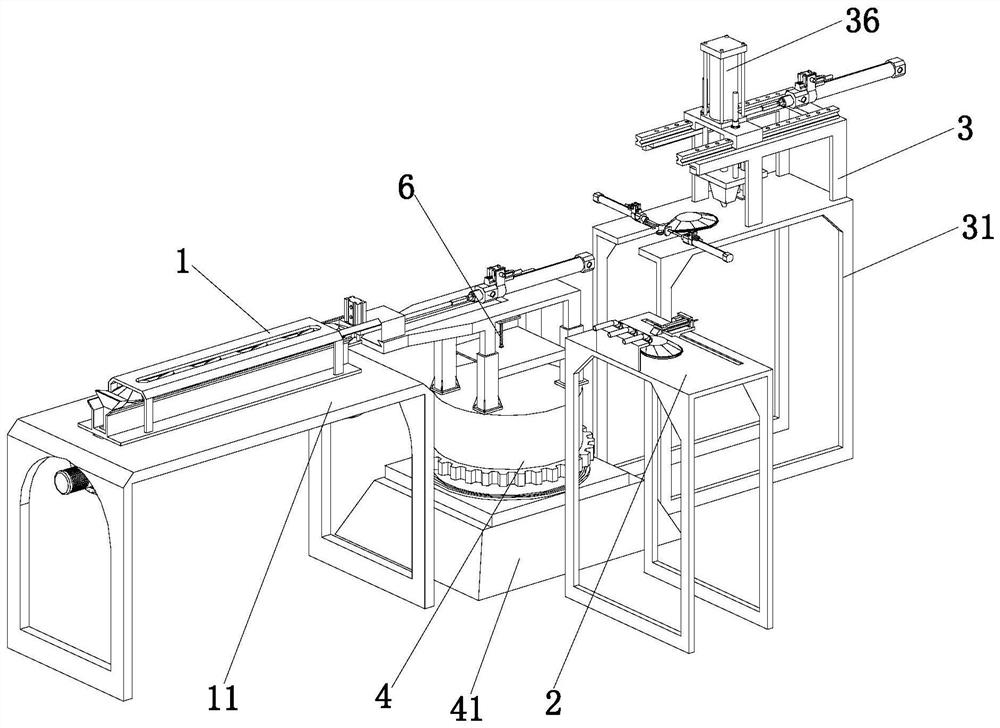

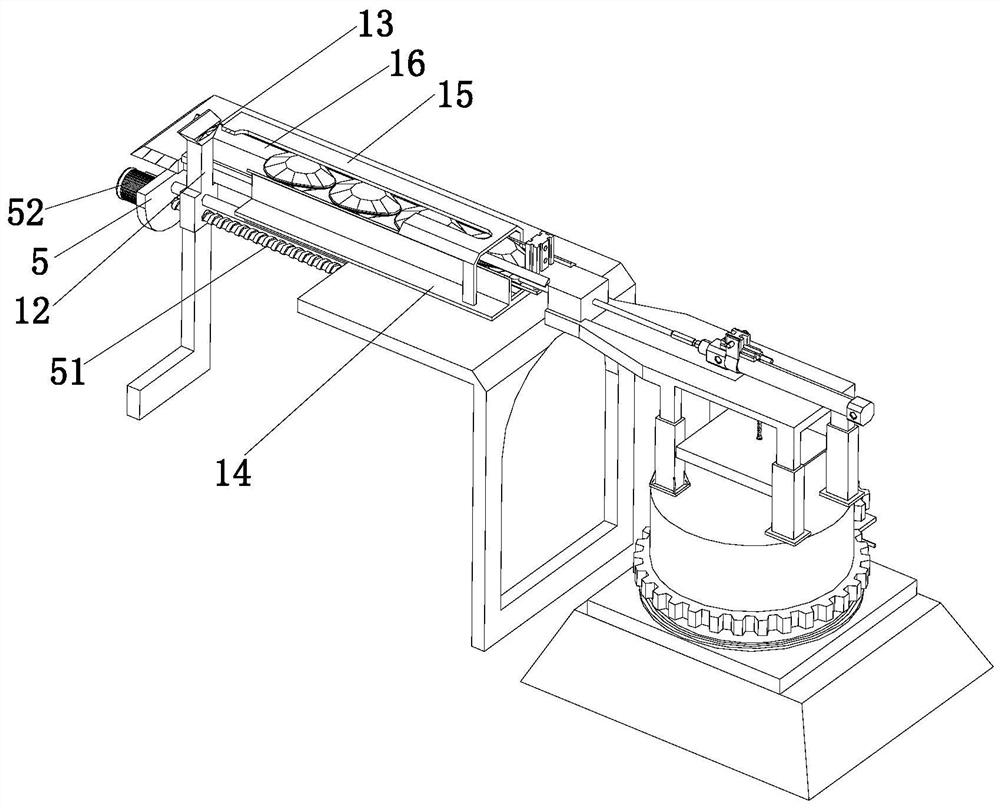

Bamboo strip edge polishing device

InactiveCN107639494AConvenient loading operationReduce labor intensityEdge grinding machinesGrinding machine componentsEngineeringManufacturing enterprises

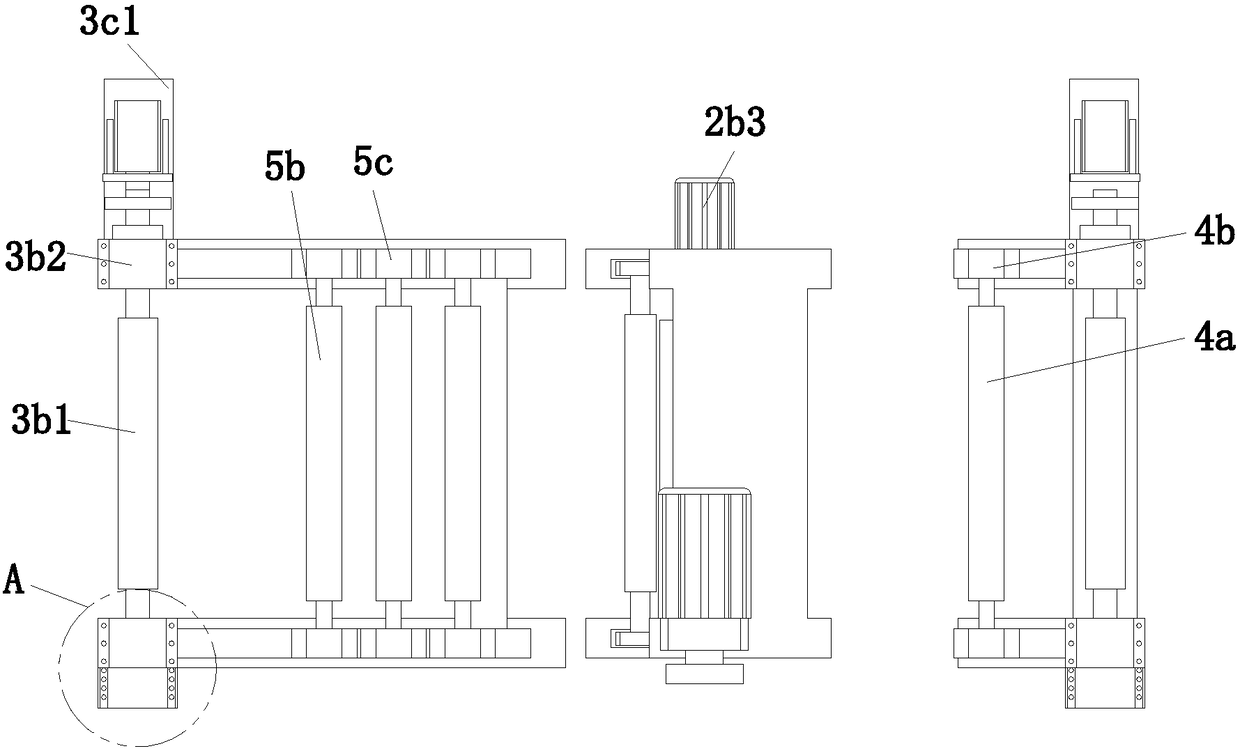

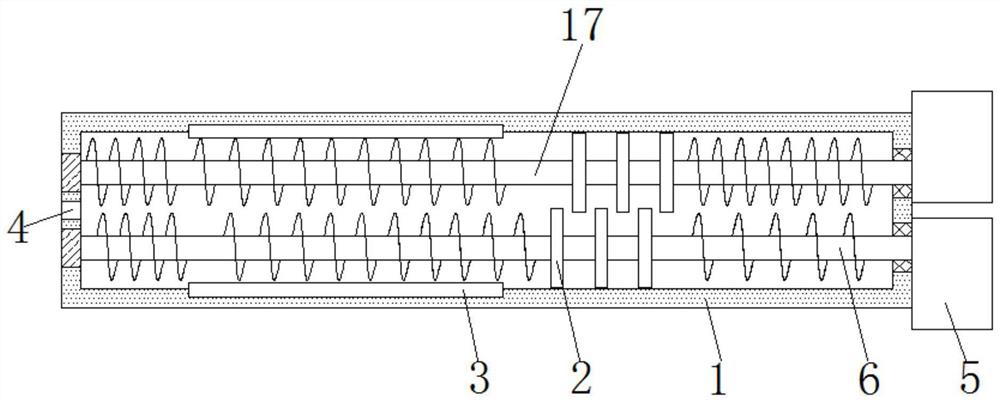

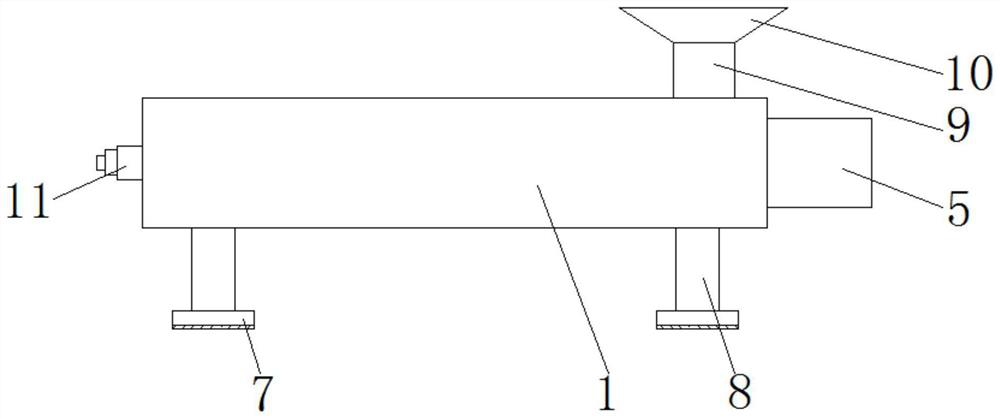

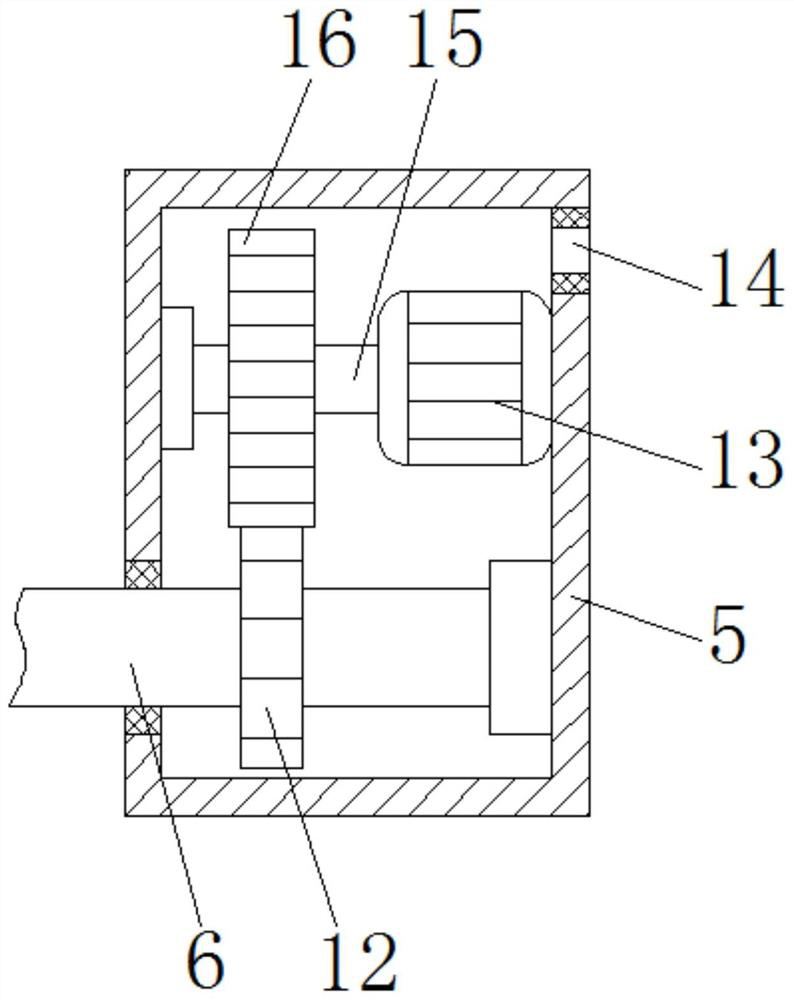

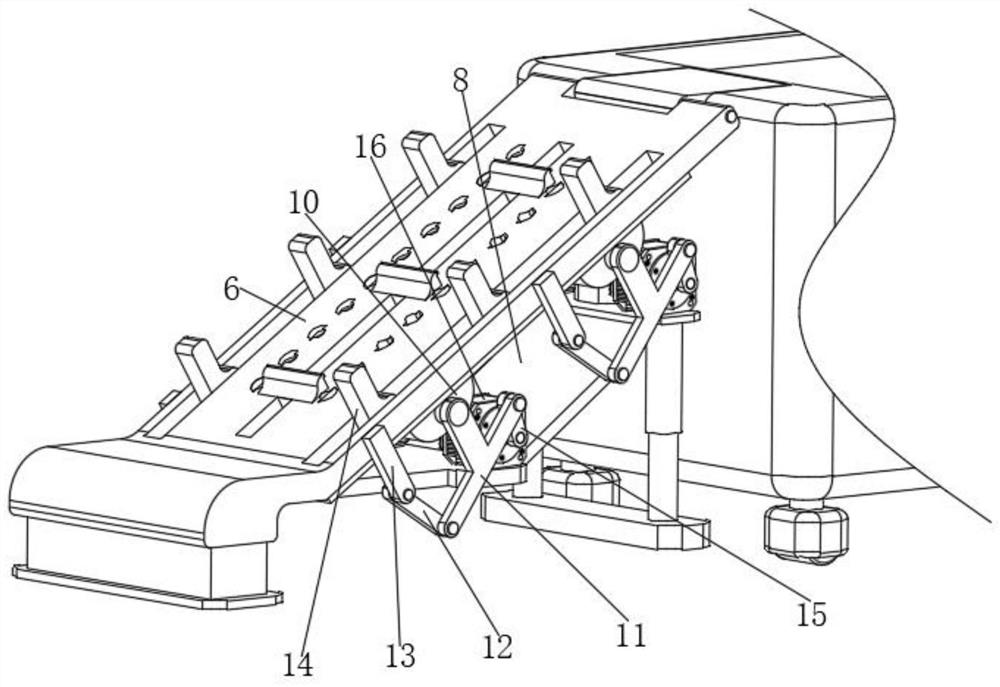

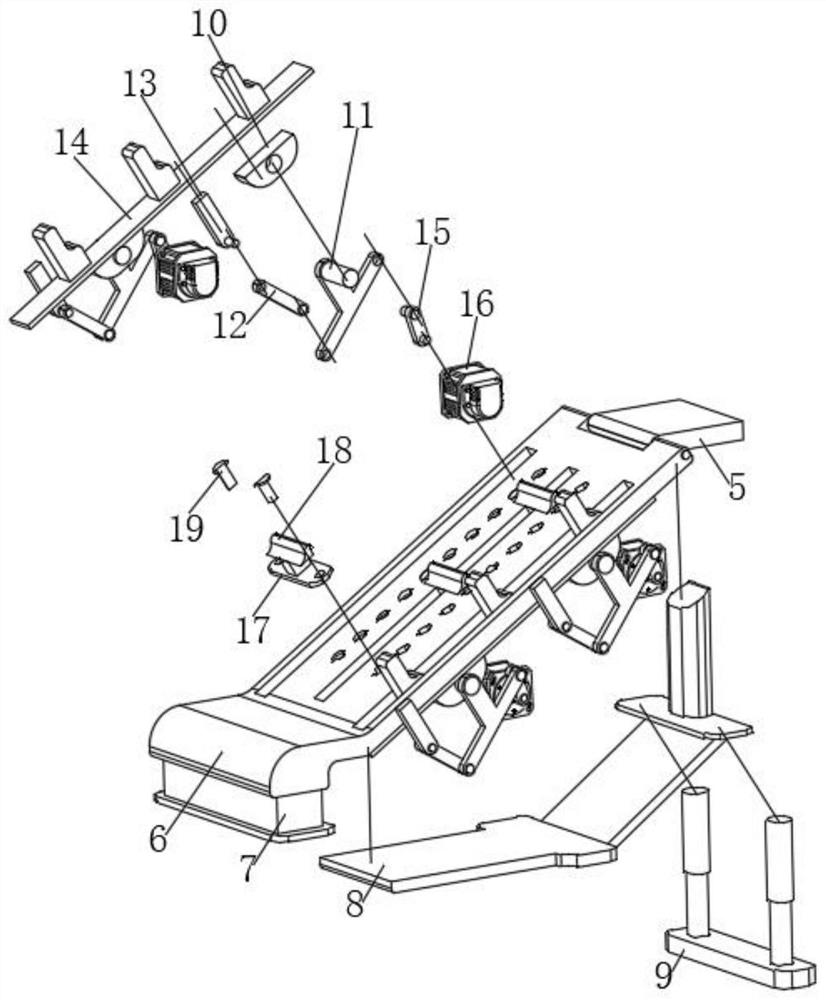

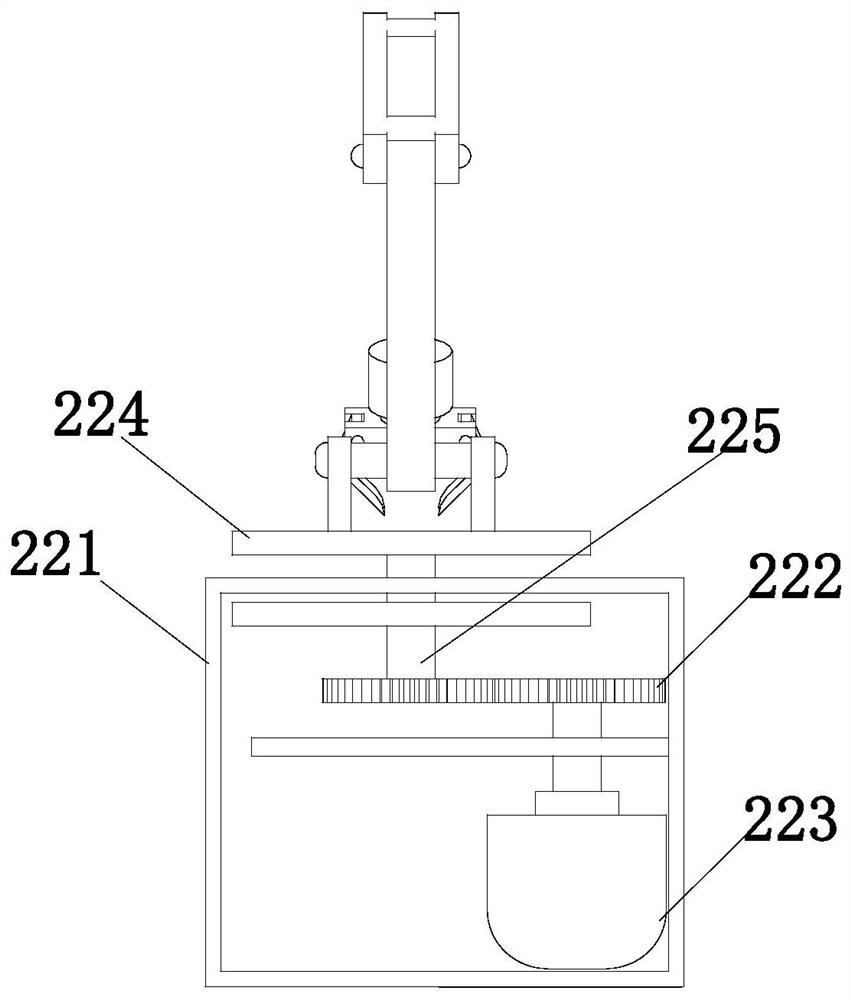

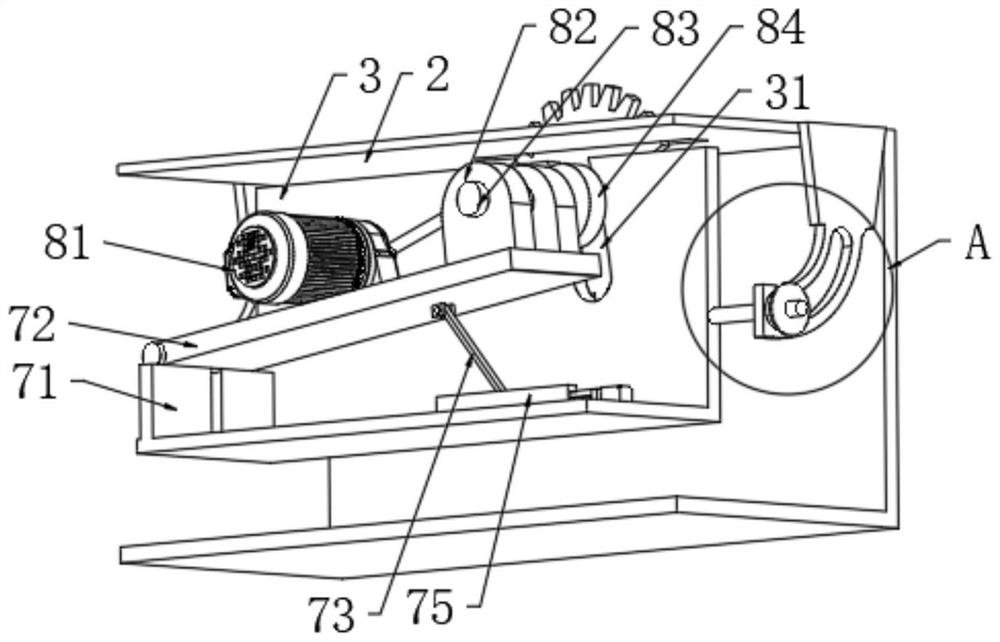

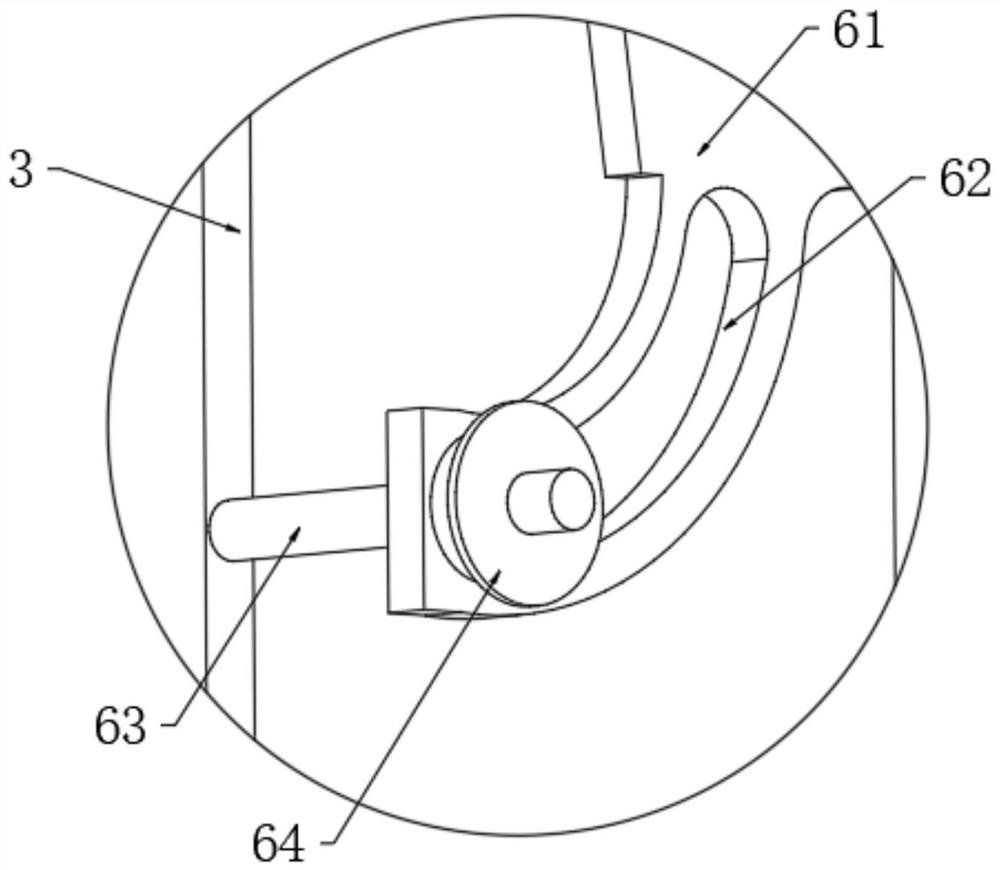

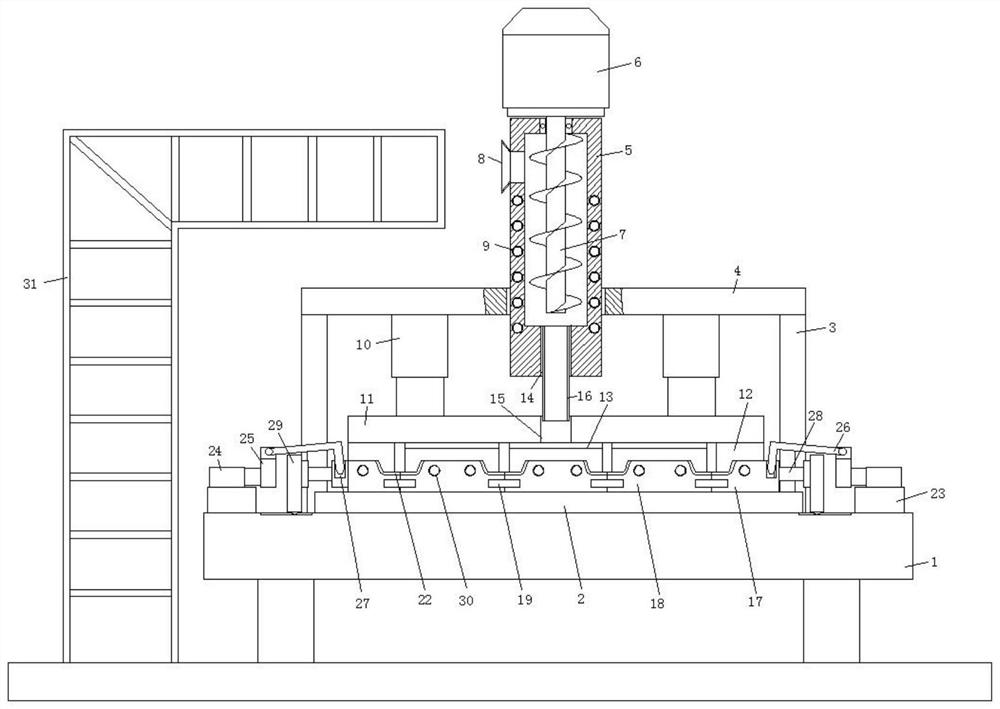

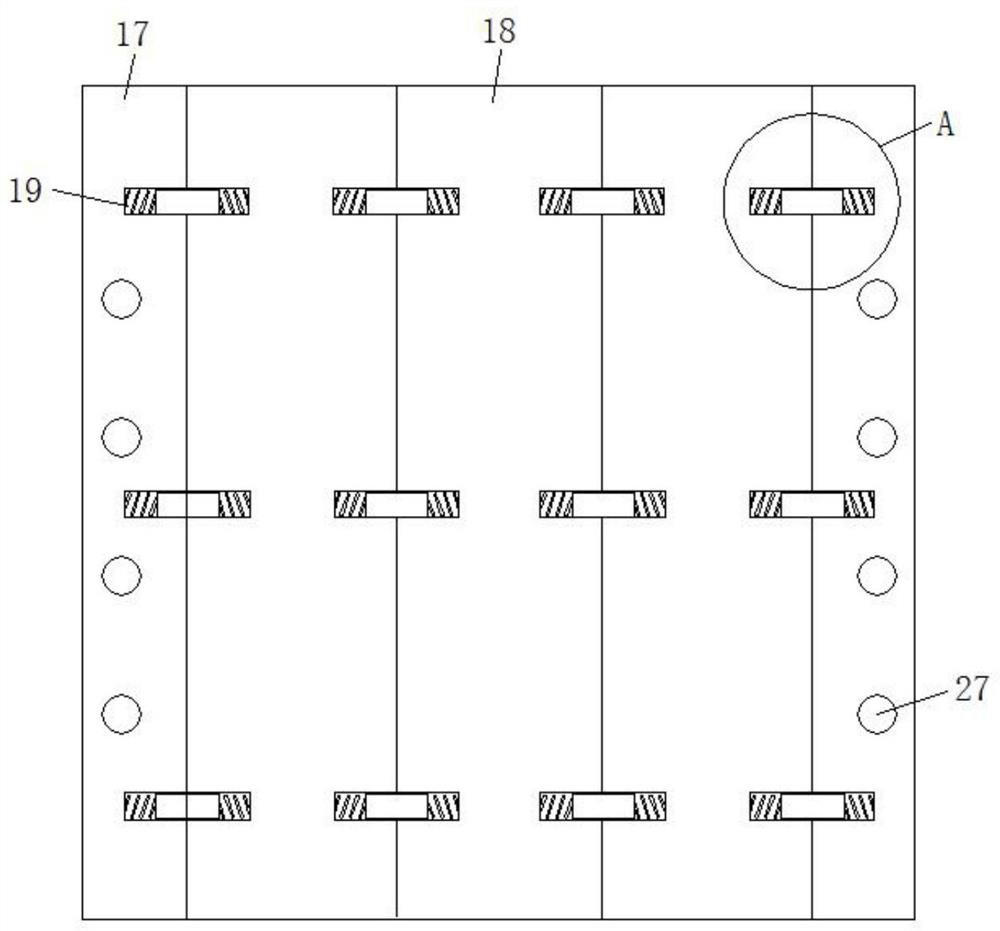

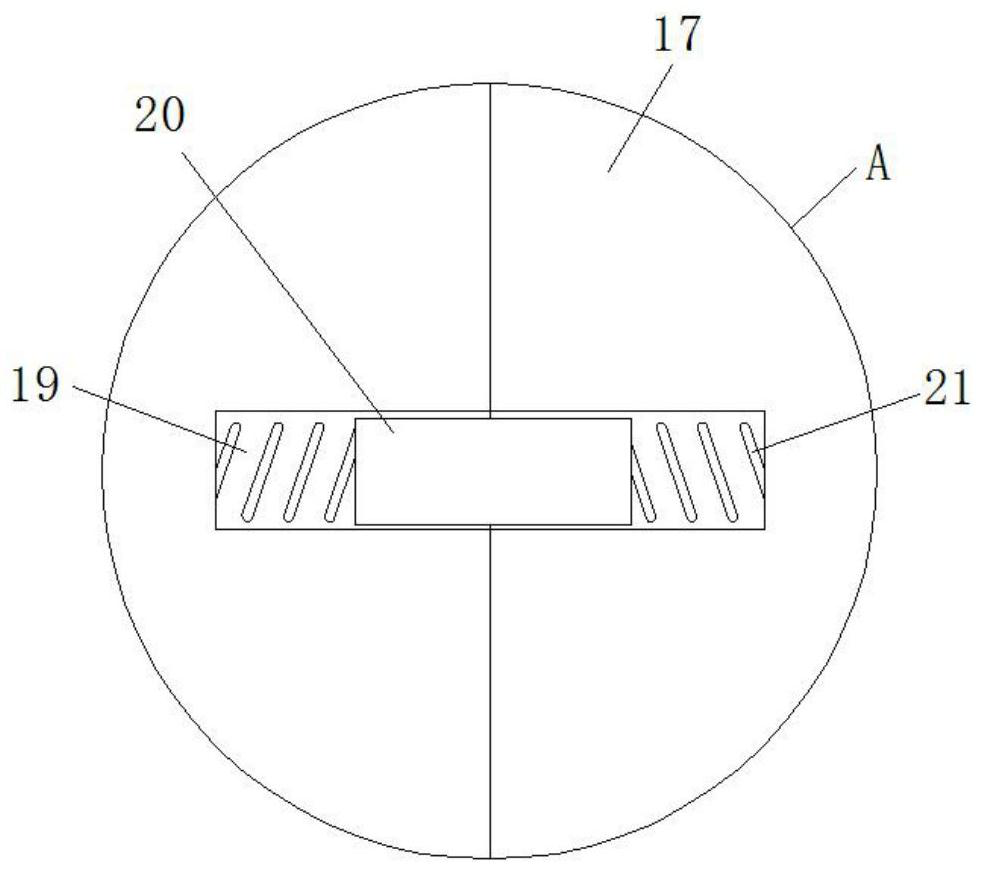

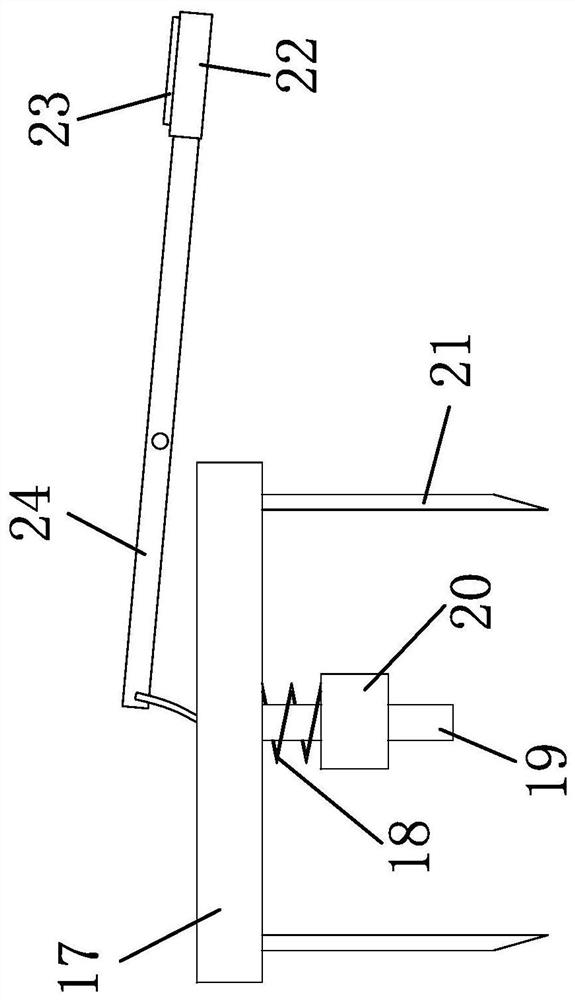

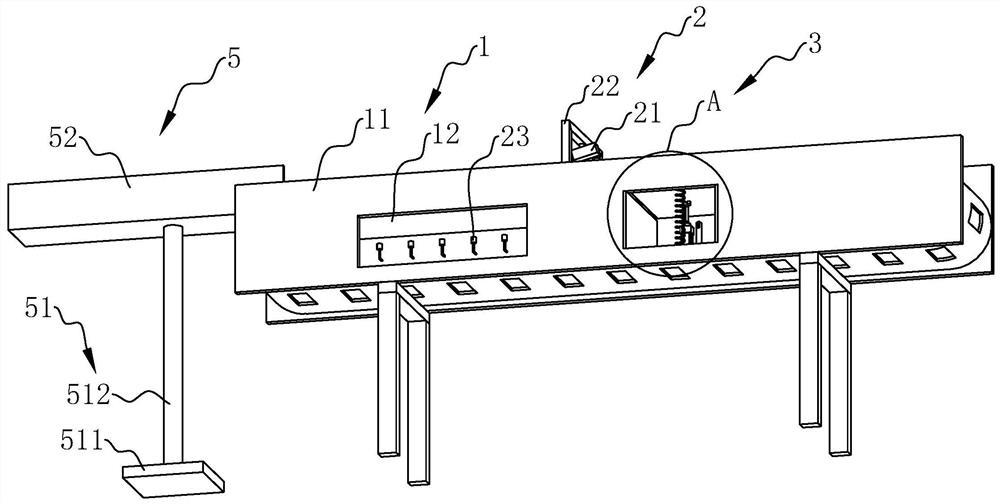

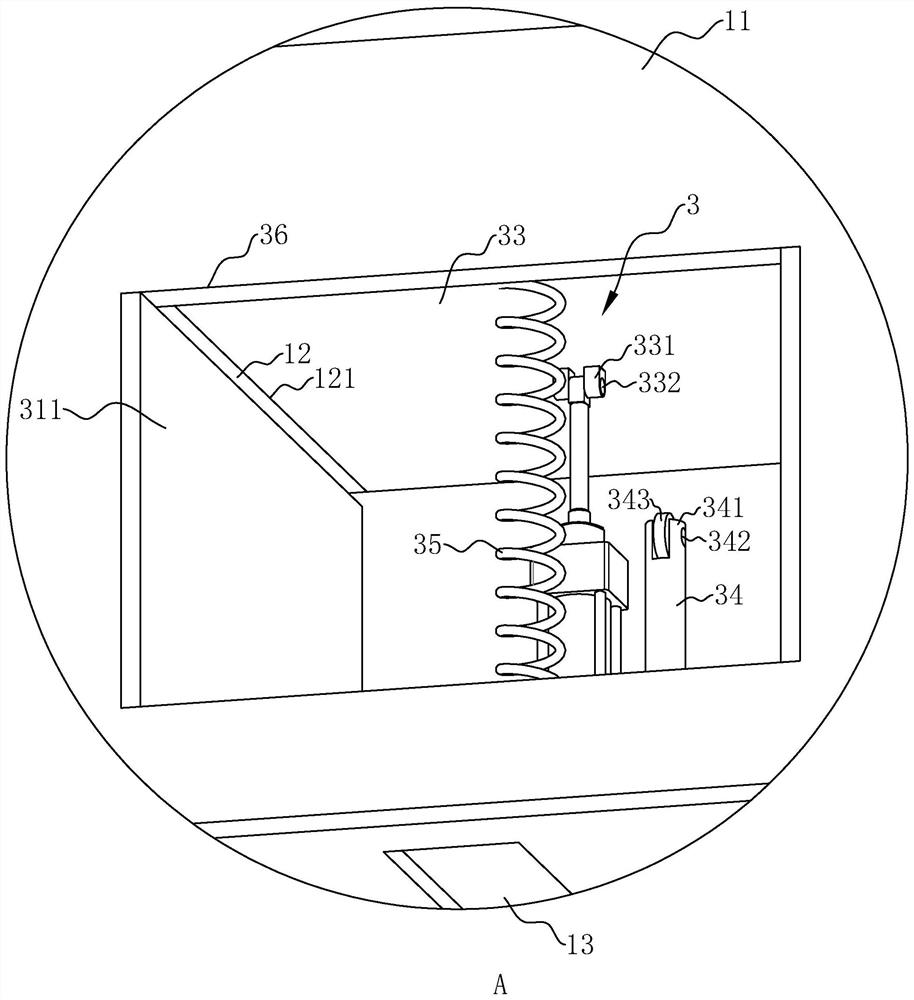

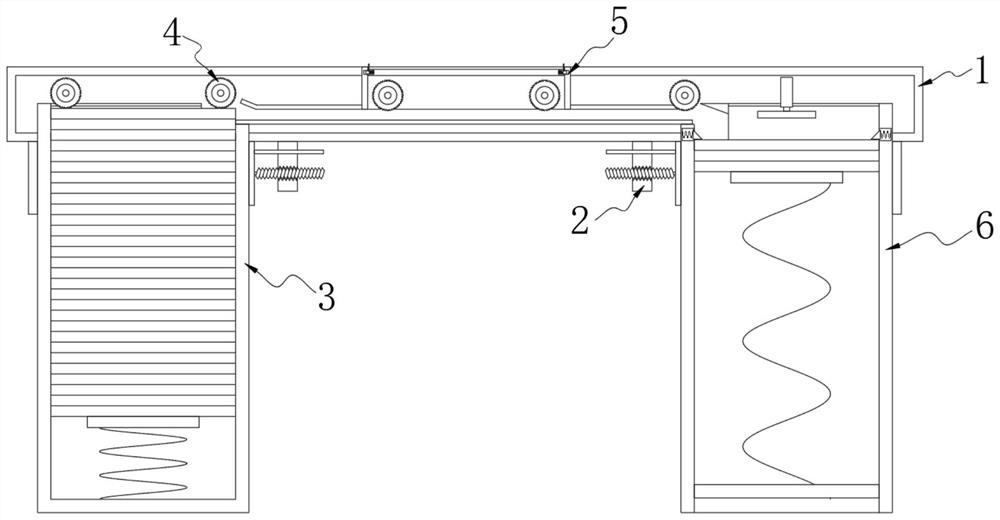

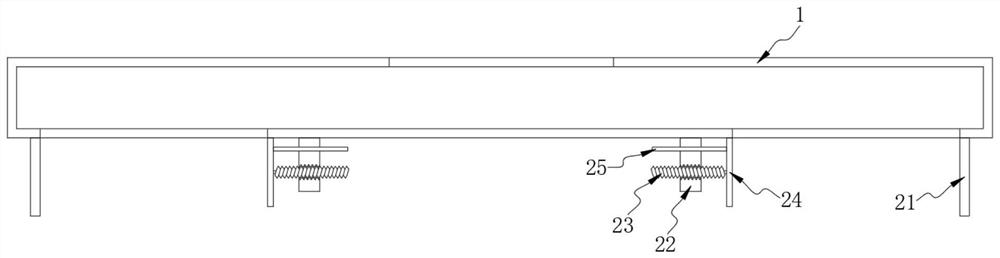

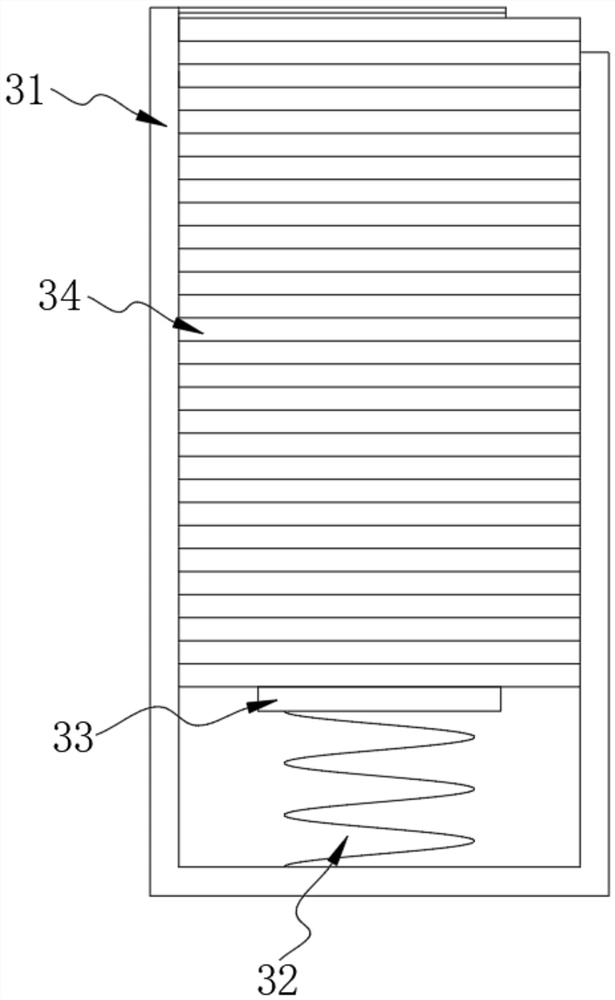

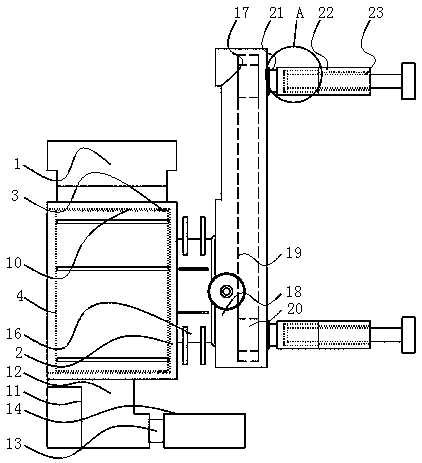

The invention relates to the field of bamboo processing equipment, in particular to a bamboo strip edge polishing device. The bamboo strip edge polishing device comprises a feeding mechanism, a material conveying mechanism and a polishing mechanism. The feeding mechanism comprises a material stocking component and material lifting components. The material lifting components comprise a first material lifting component and a second material lifting component. The polishing mechanism comprises a supporting platform, a clamping component, a turnover component, a supporting component and a polishing component, wherein the supporting platform is of a rectangular parallelepiped structure, the turnover component and the clamping component are both positioned on the top of the supporting platform.The supporting component comprises a left supporting post, a right supporting post and a top plate. A screw sliding table is arranged at the bottom of the top plate. The material conveying mechanism comprises a rotation component and a supporting table, the rotation component comprises a rotating cylinder, a bearing is arranged between the rotating cylinder and the supporting table, and the top ofthe rotating cylinder is provided with a clamping component. The bamboo strip edge polishing device does not need to manually clamp and polish the bamboo strip, prevents workers from scratching in the polishing process, improves the working efficiency of manufacturing enterprises and reduces the labor intensity of workers.

Owner:王小洪

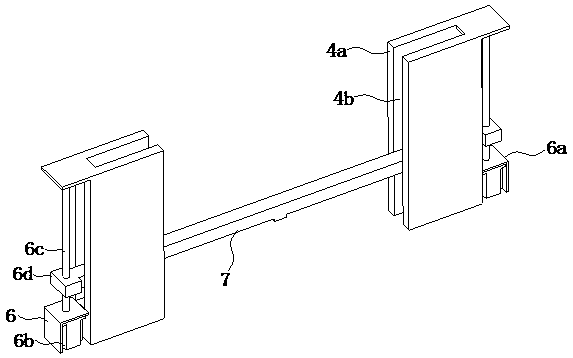

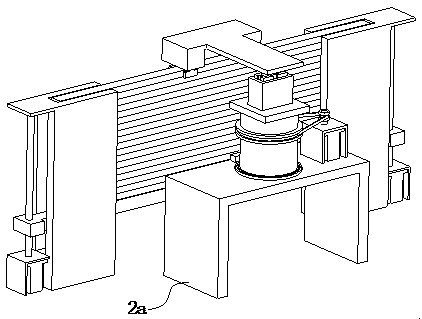

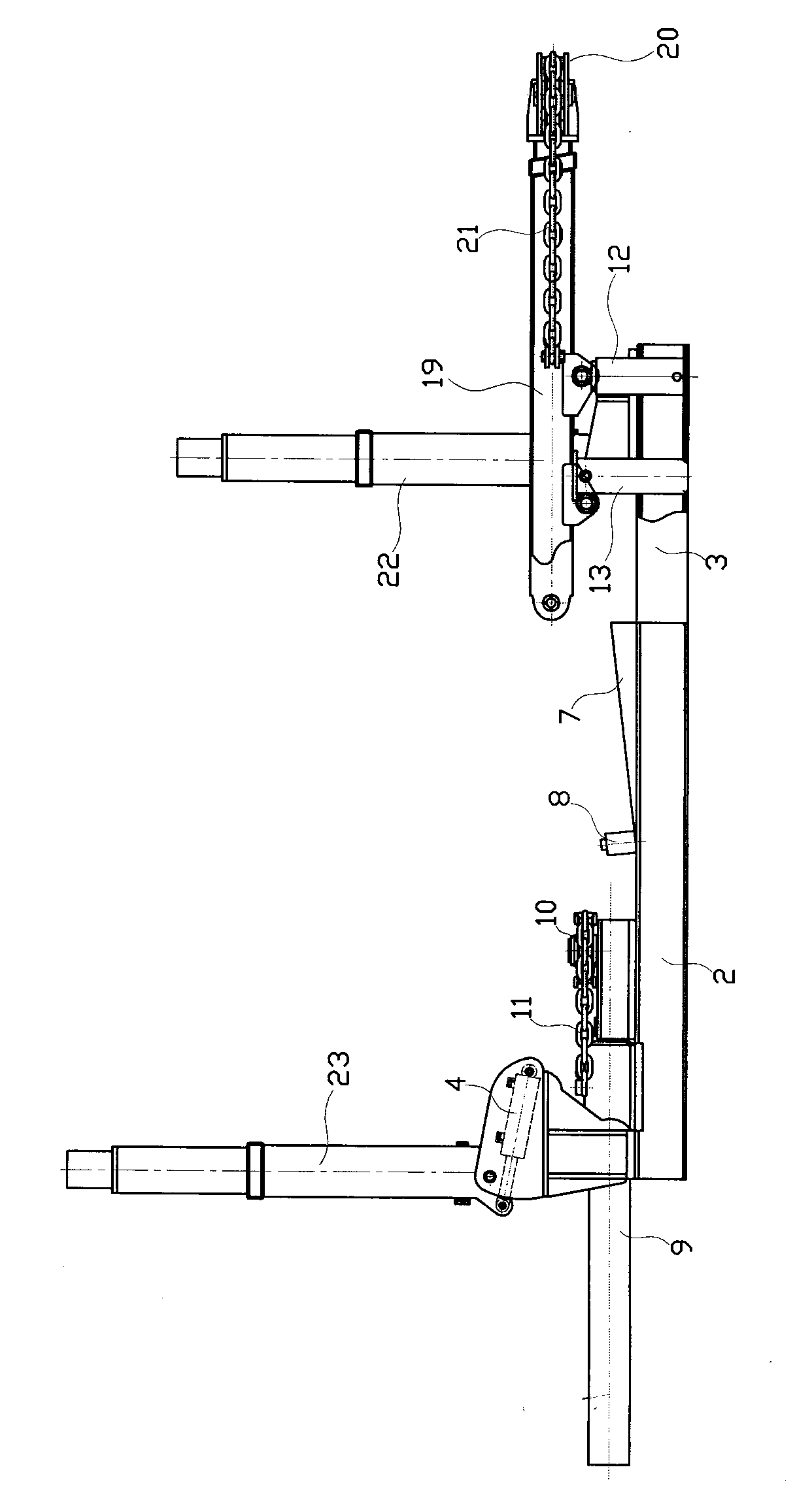

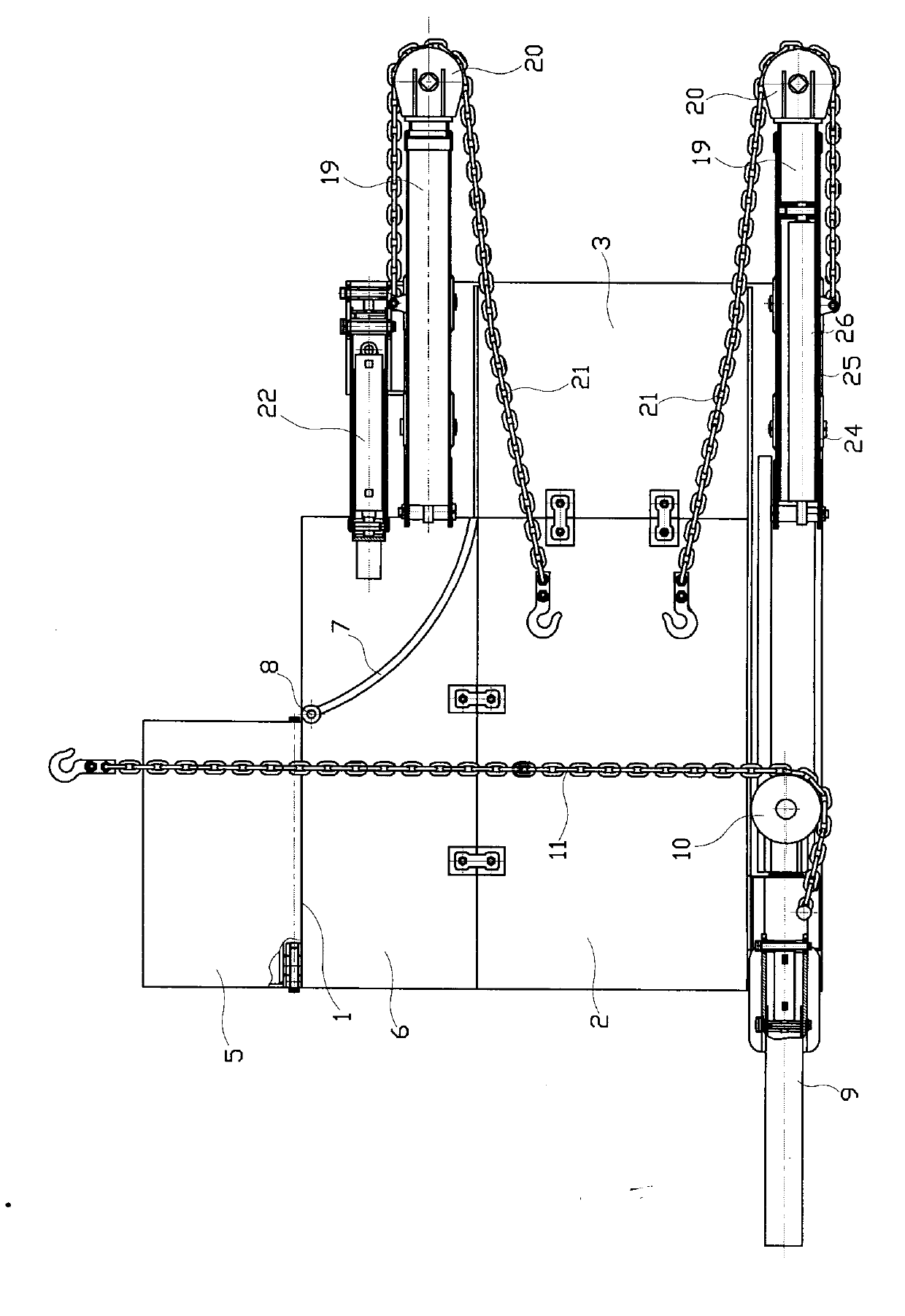

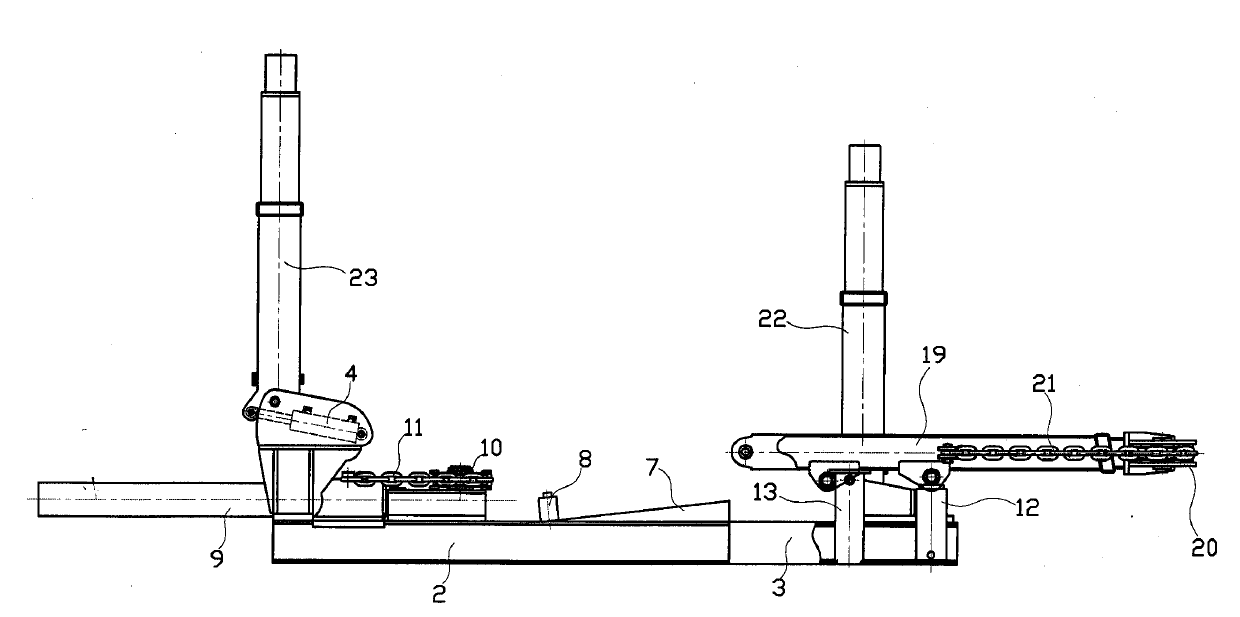

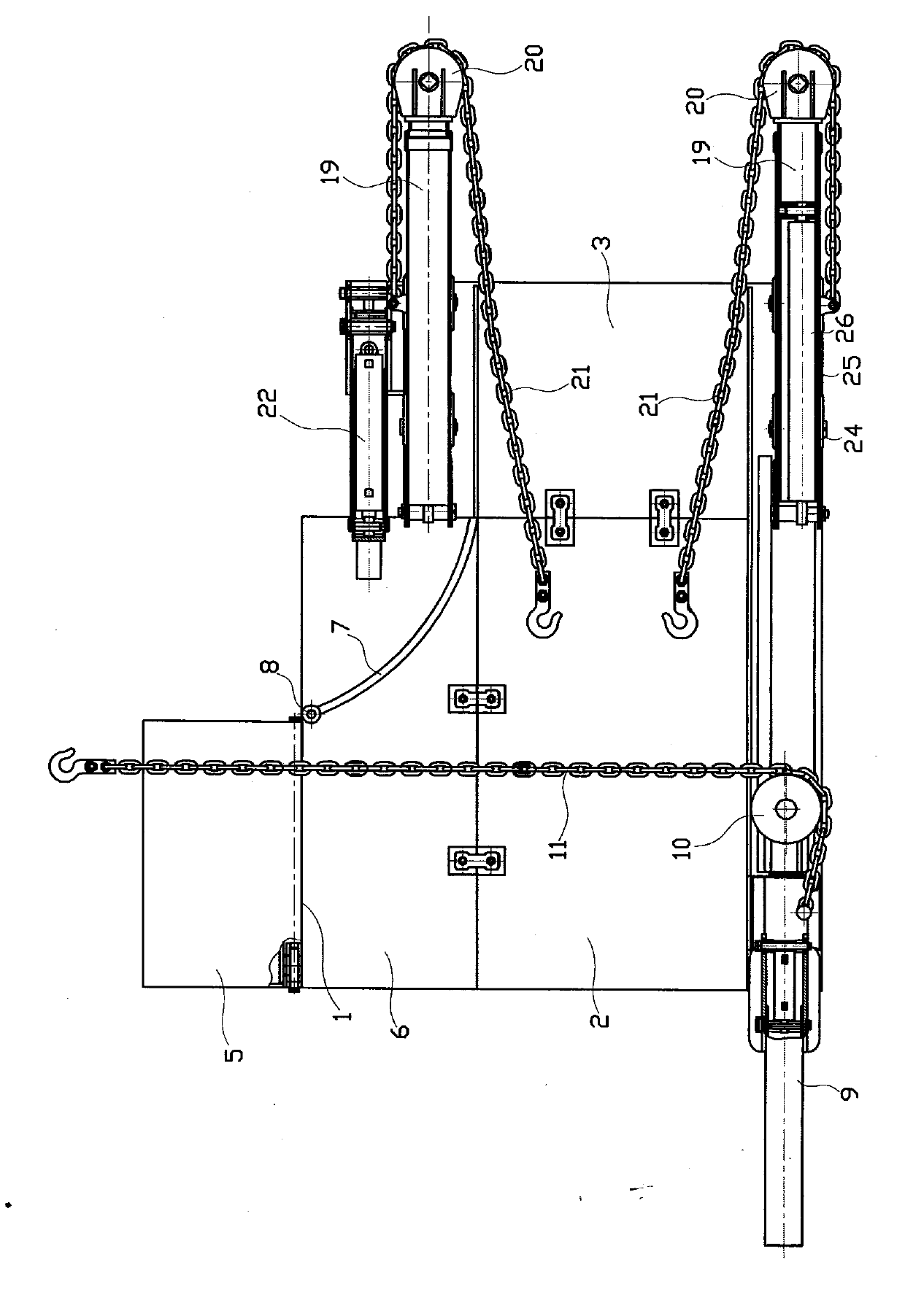

Hydraulic support steering platform

ActiveCN103195460ASimple structureReasonable arrangementMine roof supportsHydraulic cylinderControl engineering

A hydraulic support steering platform is provided with a wedge-shaped guide plate, a lifting rotation platform and a forward pulling platform which are connected. An arc convex edge and a guide post are arranged on the guide plate, a lifting rotation hydraulic telescopic arm connected with a lifting rotation sprocket is arranged in the rear of the lifting rotation platform, one end of a lifting rotation chain is connected onto the lifting rotation hydraulic telescopic arm in a positioned manner, a vertical support pulling square box and a vertical bottom lifting square box are erected on the outer side and the inner side of the forward pulling platform respectively, a hydraulic telescopic arm connected with a forward pulling sprocket is hinged to the upper ends of the support pulling square box and the bottom lifting square box, one end of a forward pulling chain is connected onto the forward pulling hydraulic telescopic arm in a positioned manner, and a front topside hydraulic cylinder and a rear topside hydraulic cylinder are hinged onto the forward pulling platform. The force application hydraulic cylinders are reasonably arranged, and the hydraulic support steering platform is simple in structure, high in force application action effectiveness and beneficial to retracement loading of a hydraulic support. The hydraulic support steering platform with the topside hydraulic cylinders is fine in stability when in use, the heights of the forward pulling platform and the forward pulling hydraulic telescopic arm can be adjusted, loading operation is facilitated, and a sprocket and chain transmission device is convenient to use.

Owner:LIAONING XINFENG MINE IND GRP CO LTD

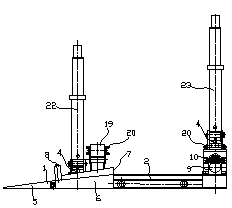

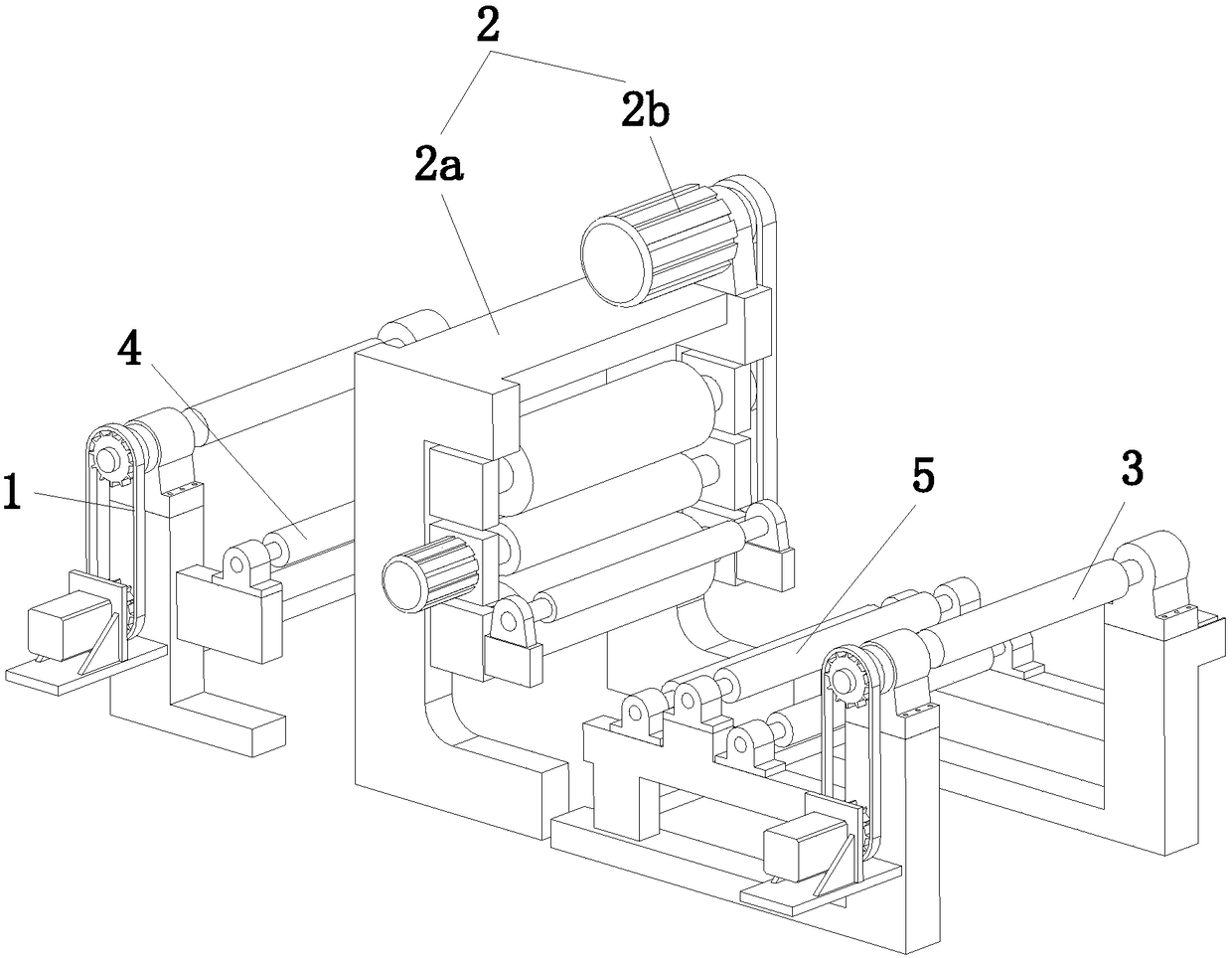

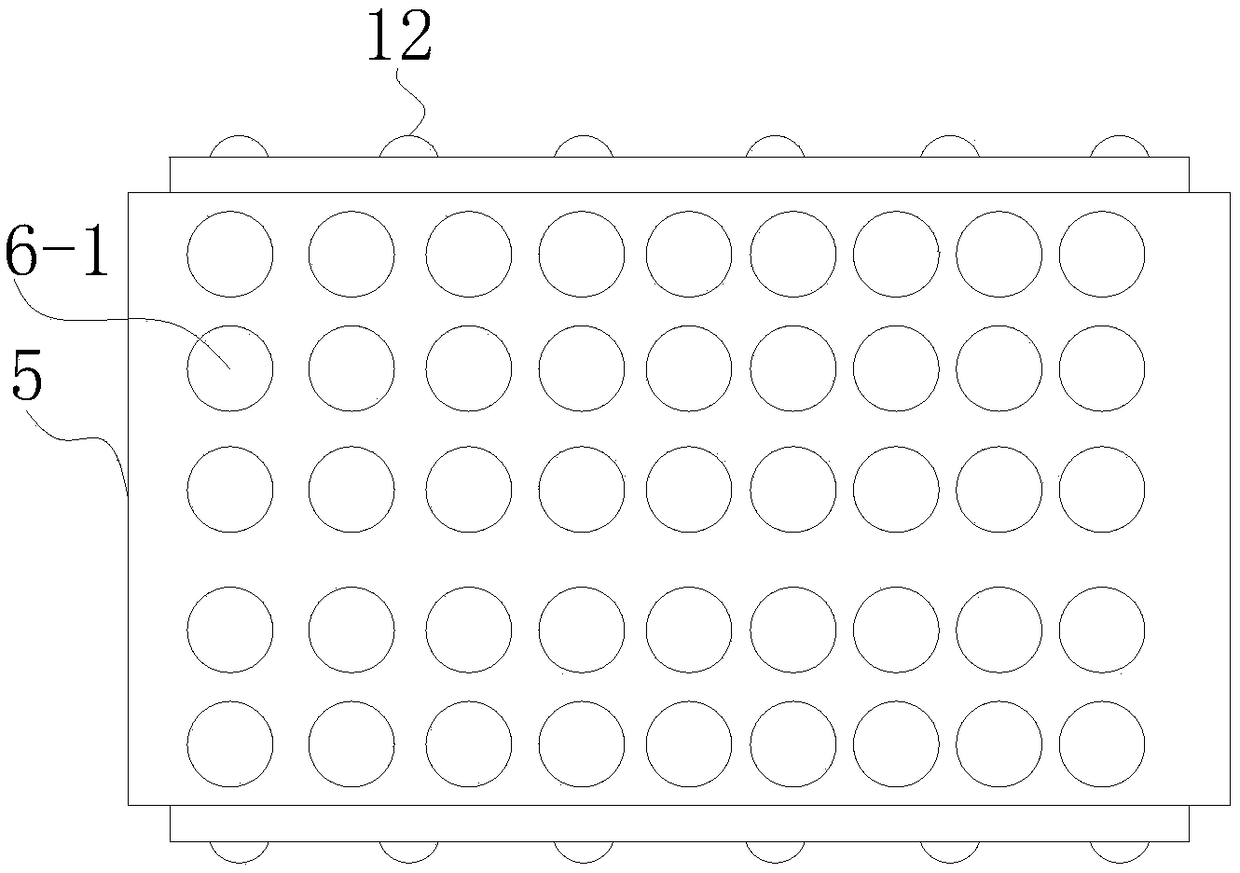

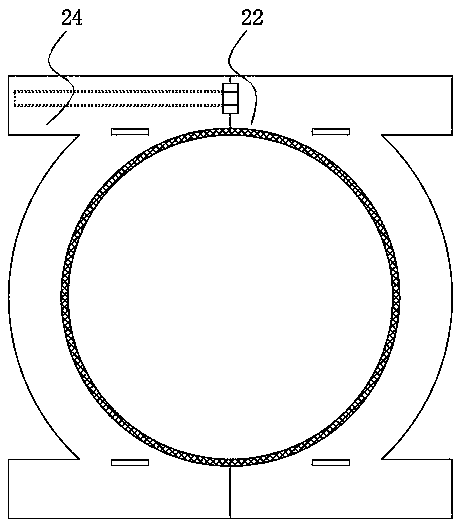

Anti-sliding film pressing forming device

PendingCN108582748ASimple structureImprove indentation effect and production pass rateEngineeringMechanical engineering

The invention relates to the field of anti-sliding film production equipment, in particular to an anti-sliding film pressing forming device. The anti-sliding film pressing forming device comprises anunwinding device, a pressing roller device and a winding device which are sequentially arranged along the anti-sliding film machining working procedure, a guide assembly is arranged between the unwinding device and the pressing roller device, a traction device is arranged between the pressing roller device and the winding device, the unwinding device and the winding device are the same in structure, the pressing roller device comprises a rack and a pressing assembly arranged on the rack, the winding device comprises a supporting frame, a winding assembly arranged on the top of the supporting frame and a first drive assembly for driving the winding assembly to rotate, the traction device comprises a fixed frame and three horizontally-arranged guide rollers mounted on the top of the fixed frame, the three guide rollers are spaced and are triangularly distributed, multiple mounting bases used for fixing the three guide rollers are arranged on the top of the fixed frame, and the fixed frame and the supporting frame are fixedly connected into a whole. The device is simple in structure, and the pressing mark effect and the production yield of the anti-sliding film can be improved.

Owner:无锡市三力胶带有限公司

Material sucking device for automatic production line

InactiveCN111823261AAchieving Regulatory ExtensionImprove feeding efficiencyGripping headsConveyor partsElectric machineryManipulator

The invention particularly relates to a material sucking device for an automatic production line. The material sucking device comprises a mounting plate; a rotary disc is fixedly arranged in the middle of the upper end of the mounting plate; an asynchronous adjustable speed motor is arranged in a groove formed in the middle of the upper end face of the rotary disc; a rotary chassis is mounted on the rotary shaft of the asynchronous adjustable speed motor; a mounting rack is fixedly arranged in the middle of the upper end of the rotary chassis; an asynchronous motor is arranged at the internalbottom of a mounting cavity formed in the mounting rack; a thread rotary shaft is rotatably connected with the output end of the asynchronous motor; and a lifting transverse rod is in thread movable joint with the thread rotary shaft. According to the material sucking device, a second gear is rotatably connected with the output shaft of the motor; and the second gear is meshed and rotatably connected with a first gear arranged on a rotary shaft; and the material sucking device can adjust the angle of a feeding manipulator, is adapted to sucking feeding operation at different angles and heights, avoids the situation that feeding is not timely due to manual feeding and improves the feeding stability and safety.

Owner:XIAN UNIV OF POSTS & TELECOMM

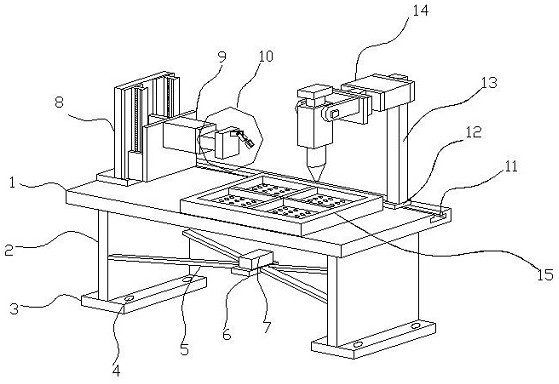

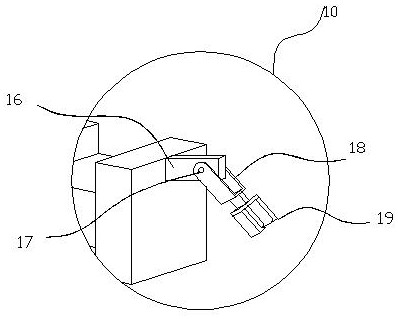

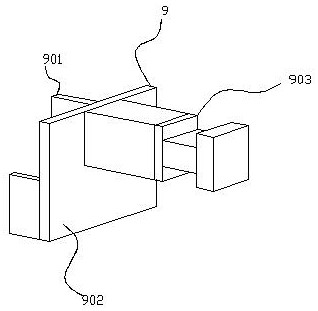

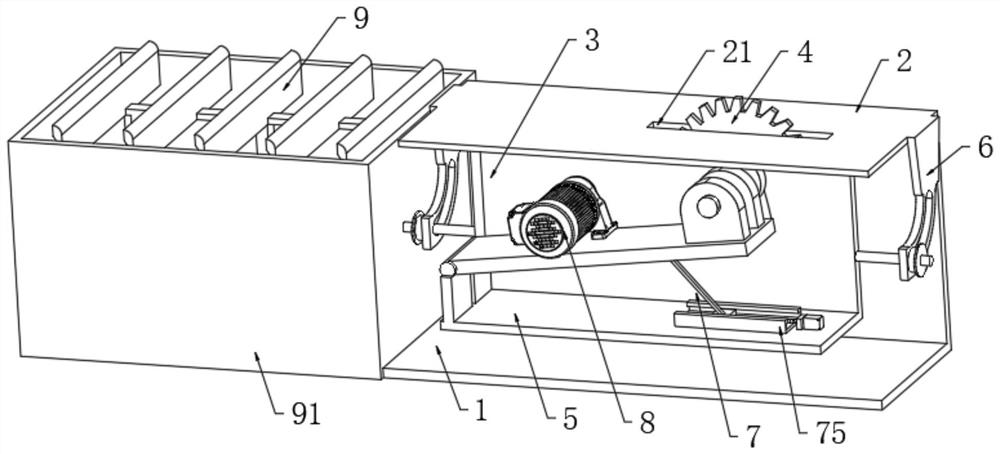

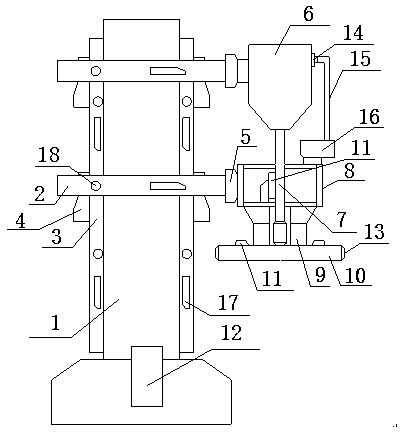

Feeding and discharging manipulator for numerical control milling machine

ActiveCN111390629AEasy to transportEasy to take outMetal working apparatusNumerical controlDrive wheel

The invention belongs to the technical field of feeding and discharging manipulators, in particular to a feeding and discharging manipulator for a numerical control milling machine. The discharging manipulator for the numerical control milling machine comprises a bottom plate, wherein a support is fixedly connected to the top of the bottom plate, a conveying device is fixedly connected to the topof the support, a connecting rod is fixedly connected to the bottom end of the conveying device, and a receiving block is fixedly connected to the bottom end of the connecting rod; a feeding device isfixedly connected to the top end of bottom plate; and a storage device is fixedly connected to the top end of bottom plate. A motor operates to drive a driving wheel to rotate, a second sliding blockreciprocates left and right on a second sliding bar by drive, a spring pushes a joint, and limit blocks slide in limit shells to drive the second sliding bar to move vertically, so that the connecting rod is driven to move periodically. Transportation of the manipulator is facilitated, conveying efficiency of the manipulator is improved, conveying stability of the manipulator is improved, takingand discharging are convenient, and the conveying effect of the manipulator is improved.

Owner:无锡惠泉凸轮轴有限公司

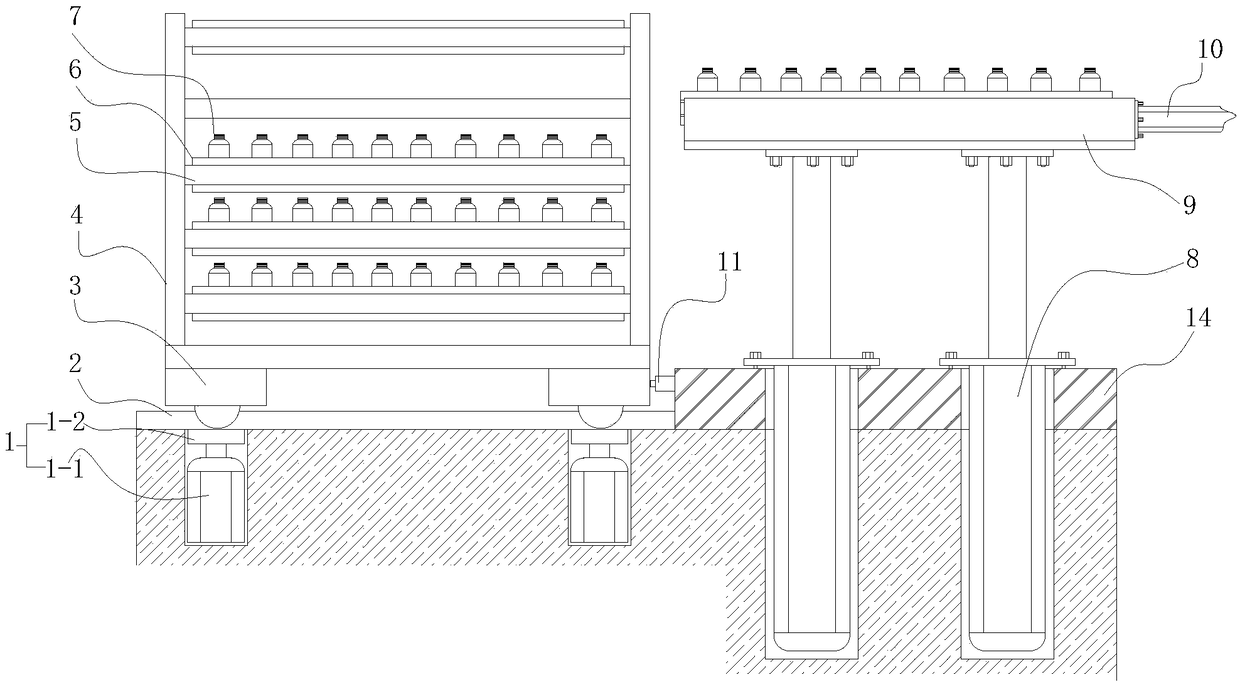

Finished glass bottle loading and placing device

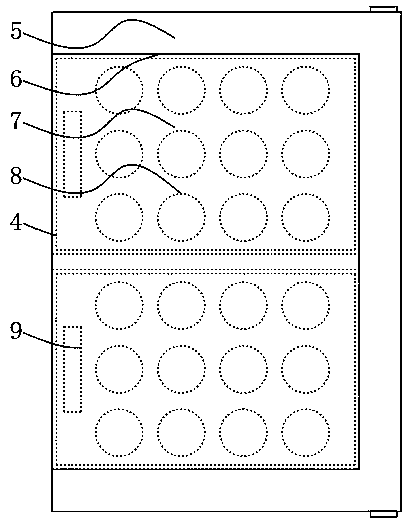

InactiveCN109250459AConvenient loading operationReduce damage rateConveyorsConveyor partsEngineeringBottle

The invention discloses a finished glass bottle loading and placing device, and relates to the technical field of glass bottle processing equipment. The finished glass bottle loading and placing device comprises a limiting guide track, a glass bottle placing device, and a glass bottle loading mechanism, wherein the limiting guide track is horizontally mounted on the ground; the glass bottle placing device comprises a storage rack and a placing plate which is arranged in the storage rack and is used for placement of glass bottles; a bottom plate is arranged at the lower end of the storage rack;multiple supporting brackets which are distributed vertically are horizontally arranged in the storage rack; strip-shaped chutes which are parallel to the supporting brackets are formed in the innerwall of the supporting brackets; column-shaped grooves for placement of the glass bottles are formed in the upper end surface of the placement plate; guiding wheels which are in rolling contact with the strip-shaped chutes are arranged on two sides of the placing plate; and the glass bottle loading mechanism comprises a lifting assembly and a lifting support plate. The finished glass bottle loading and placing device is simple in structure, loading operation of operators to finished glass bottles during placement is facilitated, the placed glass bottles cannot collide with one another and extrude, the damage rate of the glass bottles is reduced, the production cost is saved, and transfer is facilitated.

Owner:芜湖中义玻璃有限公司

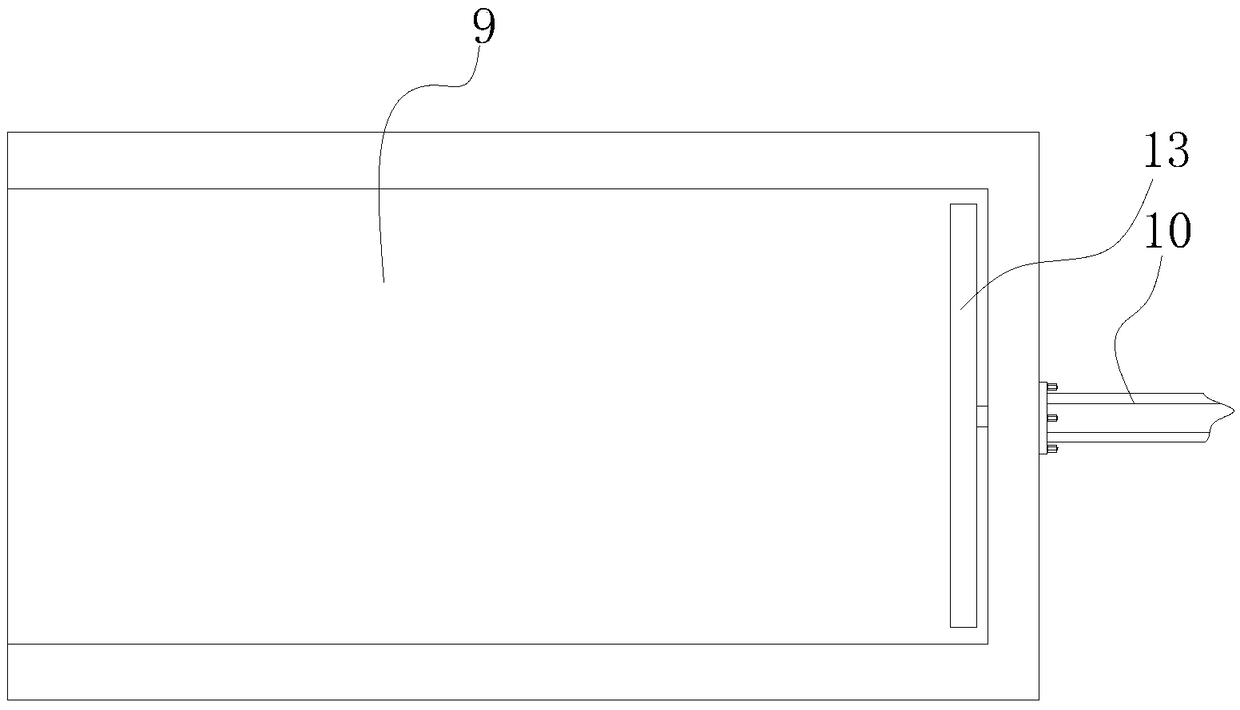

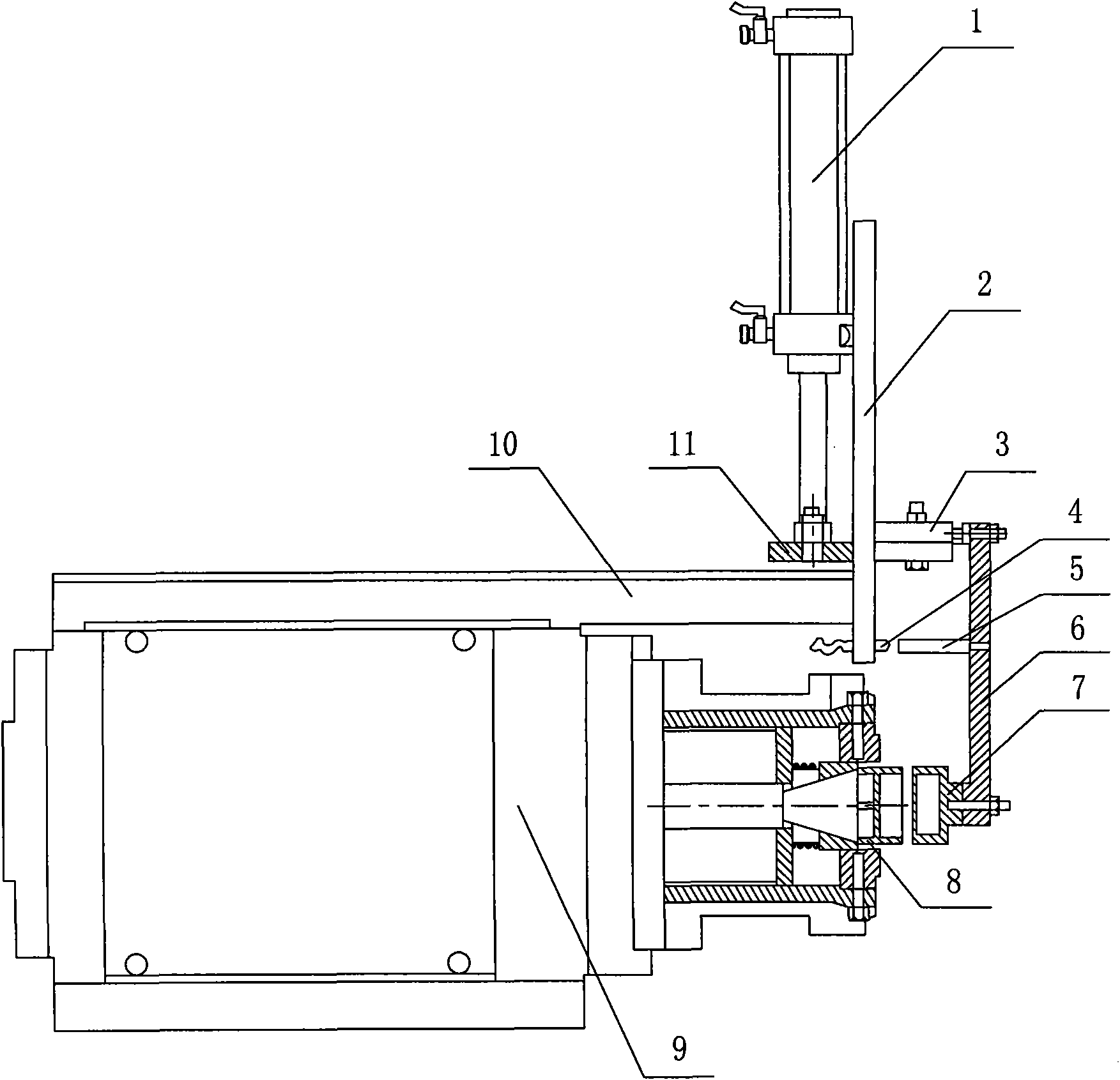

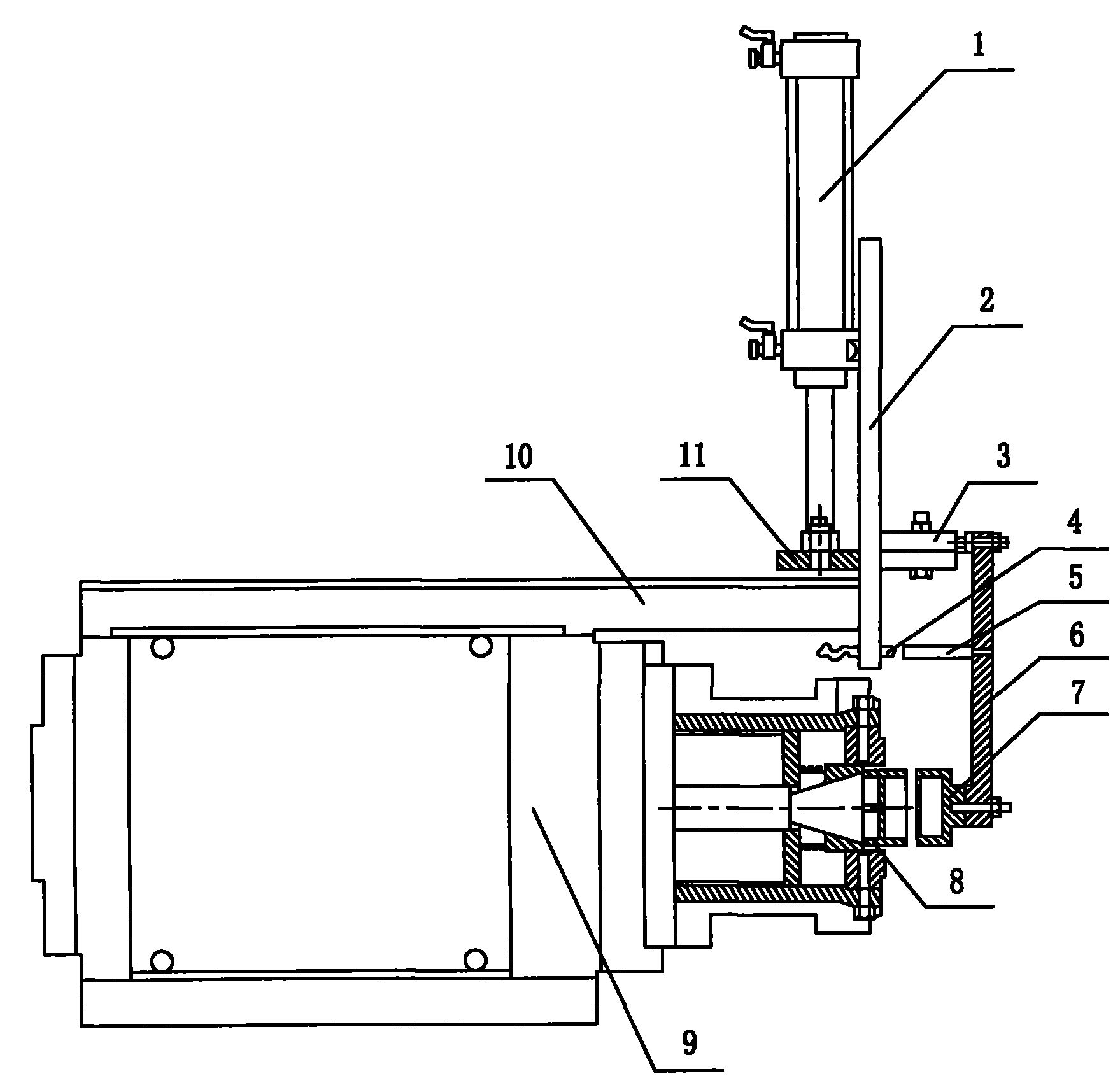

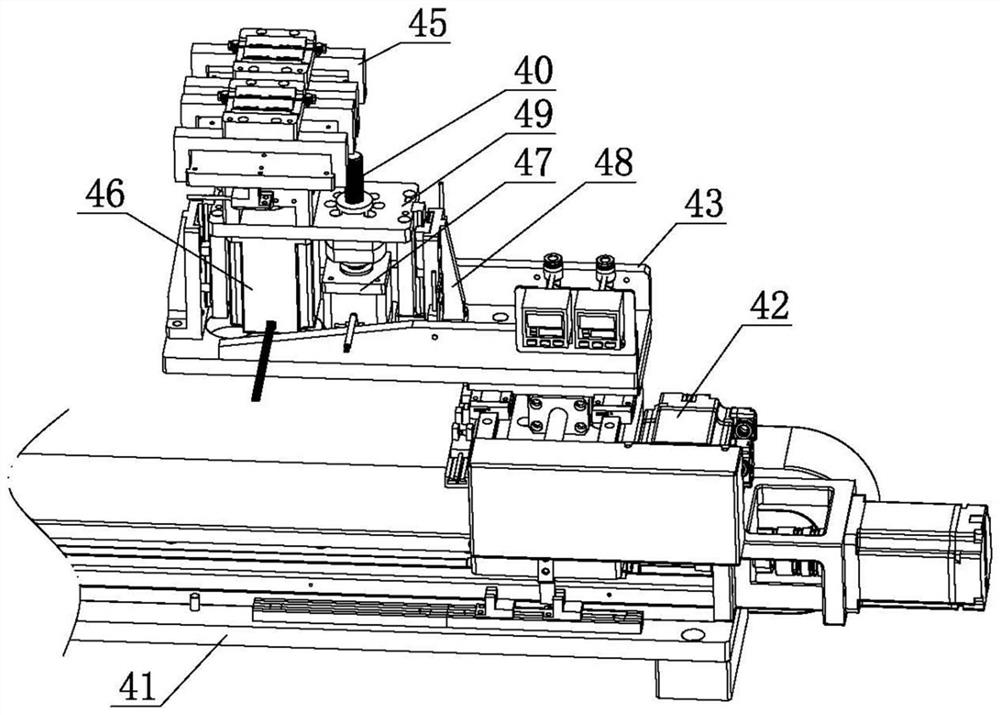

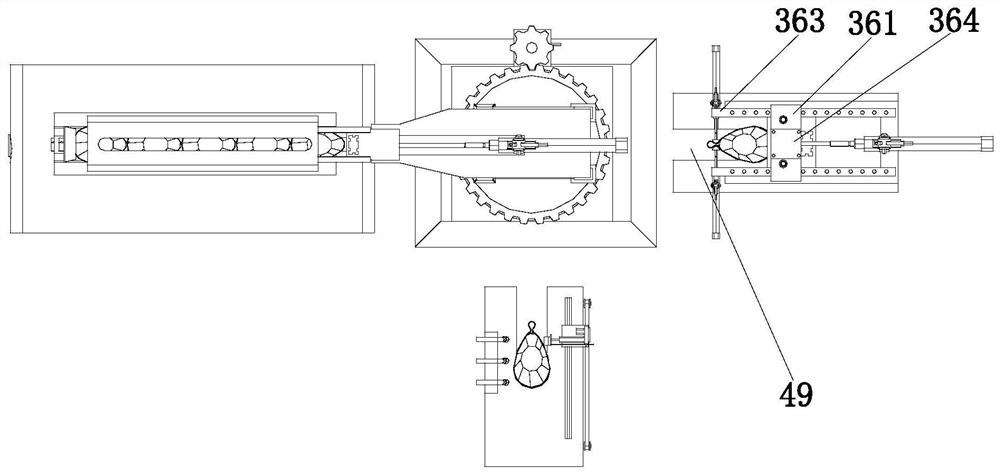

Feeding device of pre-warning bearing lathe

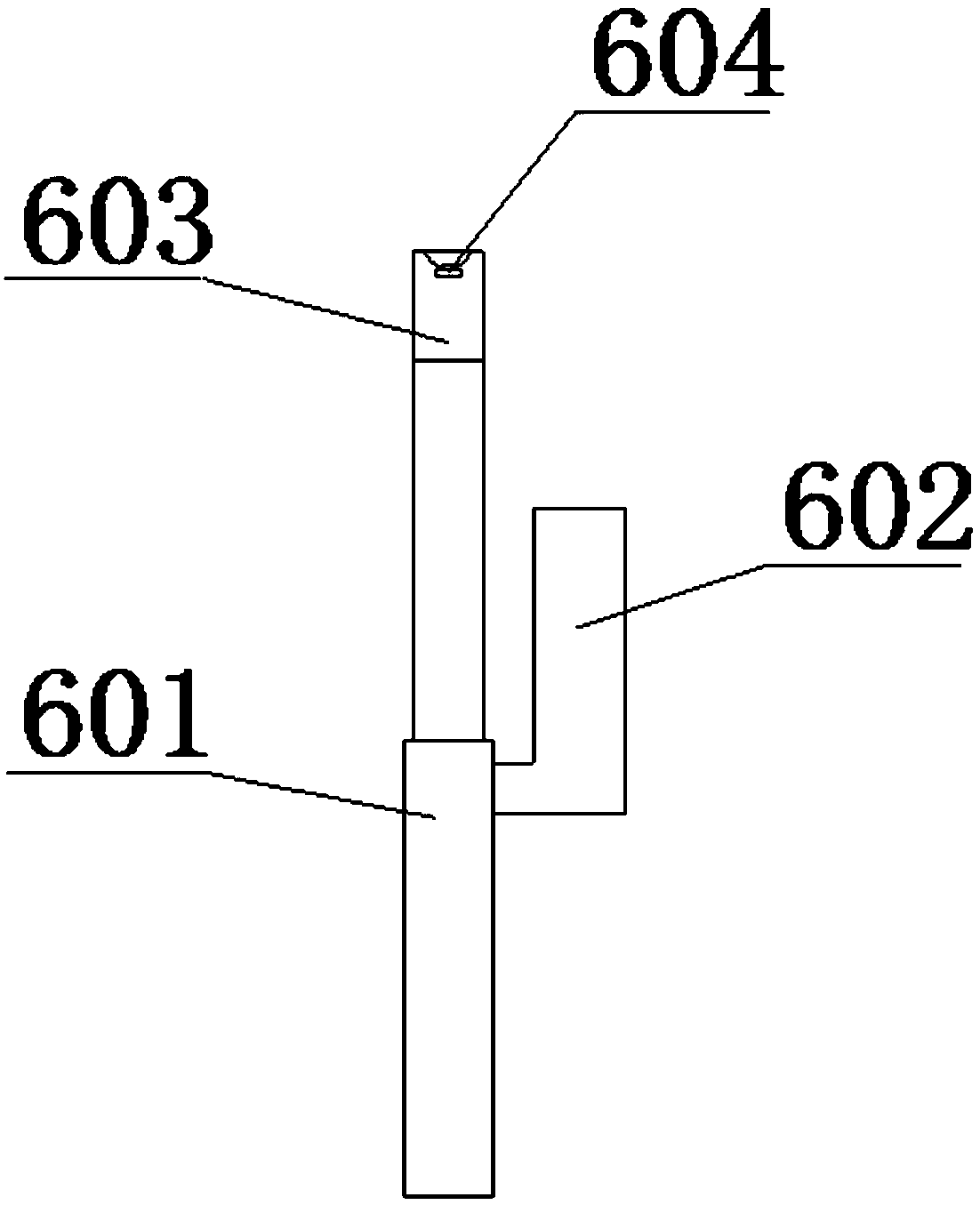

InactiveCN102485382AImprove linearityConvenient loading operationMetal-working apparatusEngineeringHeadstock

The invention relates to a feeding device of a pre-warning bearing lathe, which belongs to the field of the parts of bearing lathes. An existing feeding device has the defects that pre-warning cannot be given off after a work piece does not arrive at a processing position. The feeding device of the pre-warning bearing lathe comprises a vertical cylinder, a fixed plate, a horizontal guiding cylinder, a connecting plate, a feeding detection mechanism and a knockout mechanism; the vertical cylinder is vertically arranged on a frame through the fixed plate; a piston rod of the vertical cylinder is inserted on the connecting plate; the horizontal guiding cylinder is horizontally arranged on the connecting plate, and is connected with one end of the knockout mechanism through the piston rod of the horizontal guiding cylinder; when the vertical cylinder is in a downward maximum stroke, a clamp on a spindle of a headstock is borne on the other end of the knockout mechanism; the feeding detection mechanism comprises a trigger device and a stroke switch; the stroke switch is arranged on the fixed plate; the trigger device is over against the stroke switch and is arranged on the knockout mechanism; a stopping switch is arranged on the fixed plate; and a stopping block is arranged on the connecting plate. The feeding device of the pre-warning bearing lathe is flexible and convenient to feed, and can give off pre-warning timely.

Owner:新昌县儒岙镇翔鼠轴承机械厂

Co-rotating differential asymmetric twin-screw extruder capable of achieving continuous extruding and machining method thereof

The invention discloses a co-rotating differential asymmetric twin-screw extruder capable of achieving continuous extruding and a machining method thereof. The extruder comprises an equipment shell, and the top and the bottom of an inner cavity of the equipment shell are movably connected with a first rotating screw and a second rotating screw through bearings correspondingly; and the surfaces ofthe first rotating screw and the second rotating screw are fixedly connected with stirring cams which are arranged in a crossed manner. According to the co-rotating differential asymmetric twin-screwextruder, through the equipment shell, the stirring cams, a hot melting cavity, driving frames, the first rotating screw, an extrusion head, a driven gear, a speed regulating motor, a rotating rod, adriving gear and the second rotating screw, the device can achieve the function of a good using effect, and the problems that screw extruders on the existing market do not have the function of the good using effect, during mixed injection molding operation for multiple kinds of color masterbatch, the phenomenon that the color masterbatch mixing effect is poor, the color difference of extruded materials is large, and therefore, the product quality is influenced often occurs, and a user cannot use the screw extruders conveniently are solved.

Owner:GUANGDONG IND TECHN COLLEGE

Building material transportation device facilitating feeding for building material wholesale

InactiveCN113562098AImprove efficiency and safetyConvenient loading operationTransportation itemsVehicle with loading rampSynchronous motorBuilding material

The invention relates to the technical field of transportation devices, and discloses a building material transportation device facilitating feeding for building material wholesale. The building material transportation device comprises a transportation device body, a fixing plate is mounted at the front end of the transportation device body, a feeding bottom plate is rotatably connected to the front end of the fixing plate, limiting grooves are formed in the two sides of the feeding bottom plate, and pushing modules are mounted in the limiting grooves. According to the building material transportation device facilitating feeding for building material wholesale, limiting grooves are formed in the two sides of the feeding bottom plate, pushing modules are installed in the limiting grooves, a synchronous motor can conveniently drive a transmission rod to rotate, meanwhile, a connecting rod is driven to operate, the pushing modules on the two sides are pushed to gradually lift and feed materials, meanwhile the limiting modules are matched, the material on the surface of the feeding bottom plate is limited, the feeding efficiency and safety are improved, and therefore the problems that during feeding, the device needs to be manually held, and the material is likely to slide off in the feeding process are solved.

Owner:怀化明达建材有限公司

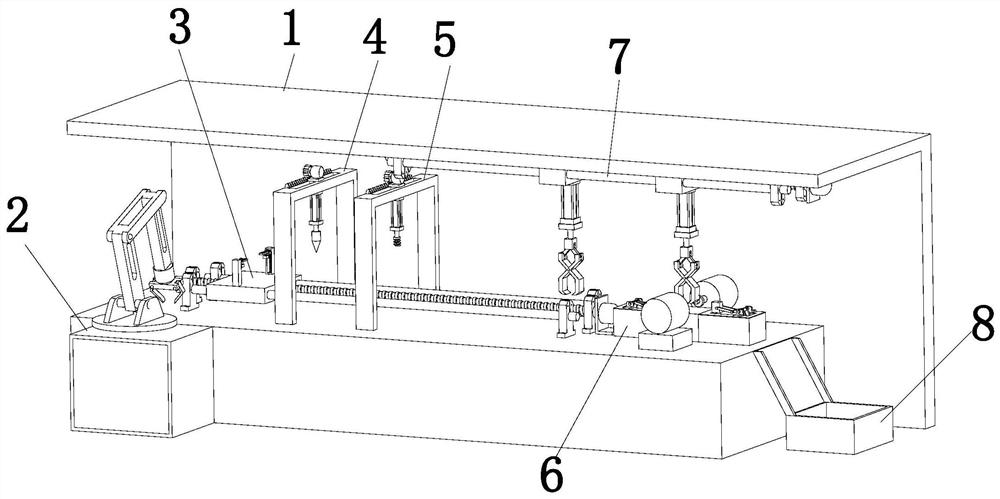

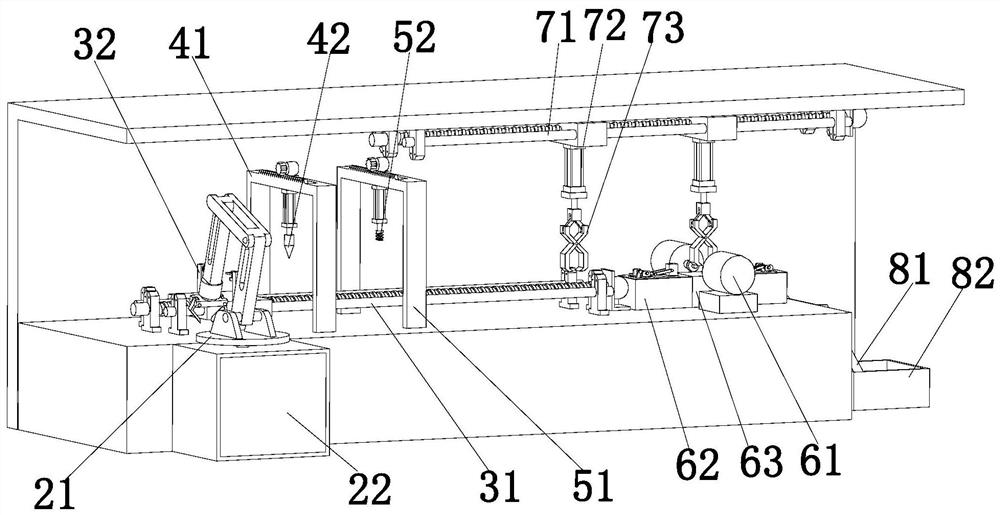

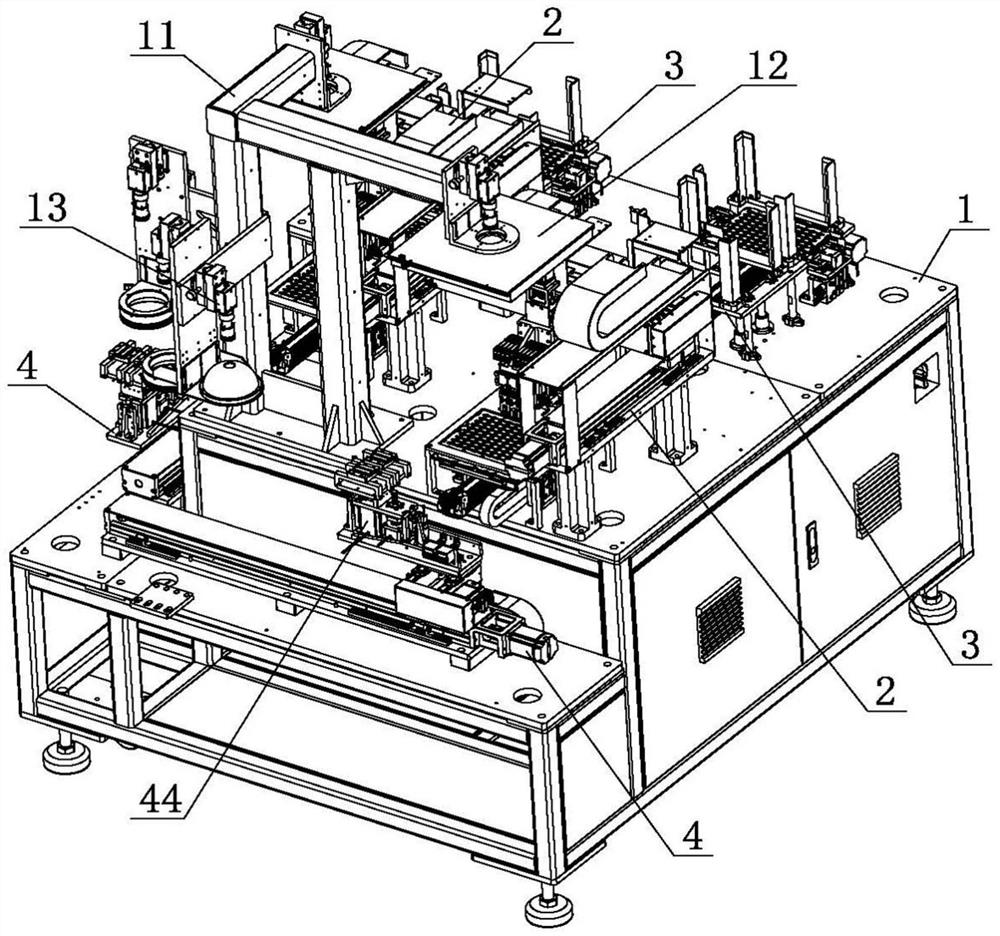

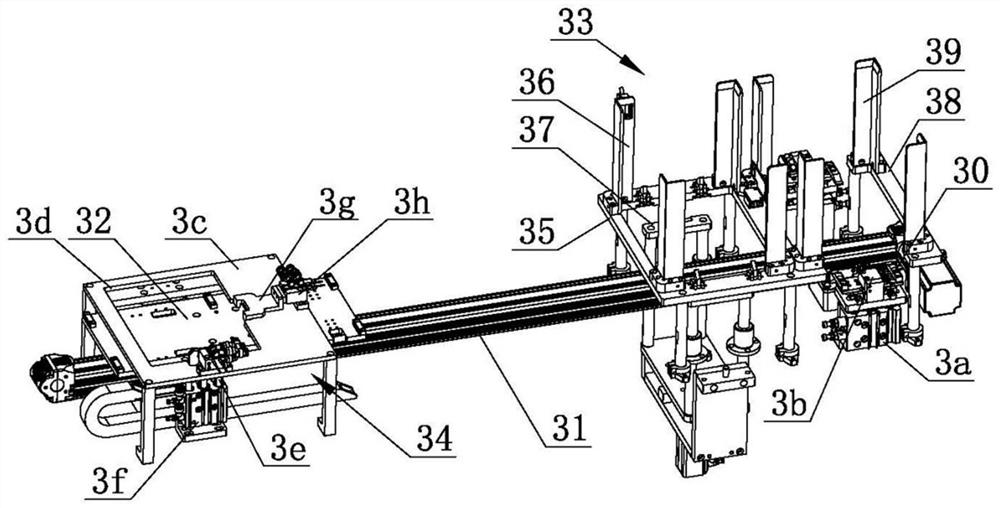

Automatic machining process for special-shaped iron sheet

The invention discloses an automatic machining process for a special-shaped iron sheet, and relates to the field of iron sheet machining. The automatic machining process comprises the following stepsthat 1, the special-shaped iron sheet is automatically fed; 2, the special-shaped iron sheet is fixed; 3, the special-shaped iron sheet is automatically drilled; 4, the special-shaped iron sheet is automatically tapped; 5, the special-shaped iron sheet is automatically grabbed; 6, the special-shaped iron sheet is automatically chamfered; 7, the machined special-shaped iron sheet is automatically discharged. The automatic machining process is ingenious in design and smooth in procedure connection, automatic feeding of the special-shaped iron sheet, fixing, drilling, tapping, grabbing and chamfering of the special-shaped iron sheet and automatic discharging of the machined special-shaped iron sheet are achieved, automatic production of the special-shaped iron sheet is achieved, the automation degree is high, the efficiency is greatly improved, and the automatic machining process has remarkable economic value.

Owner:尹艳元

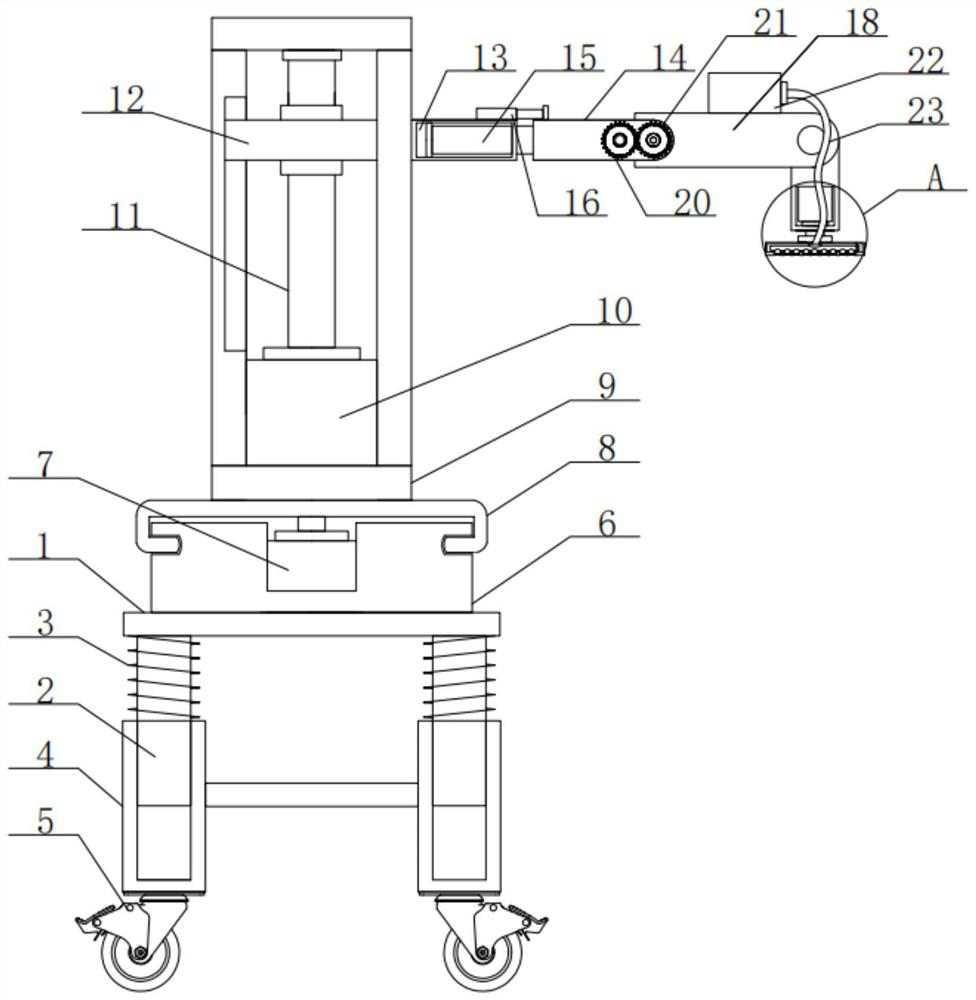

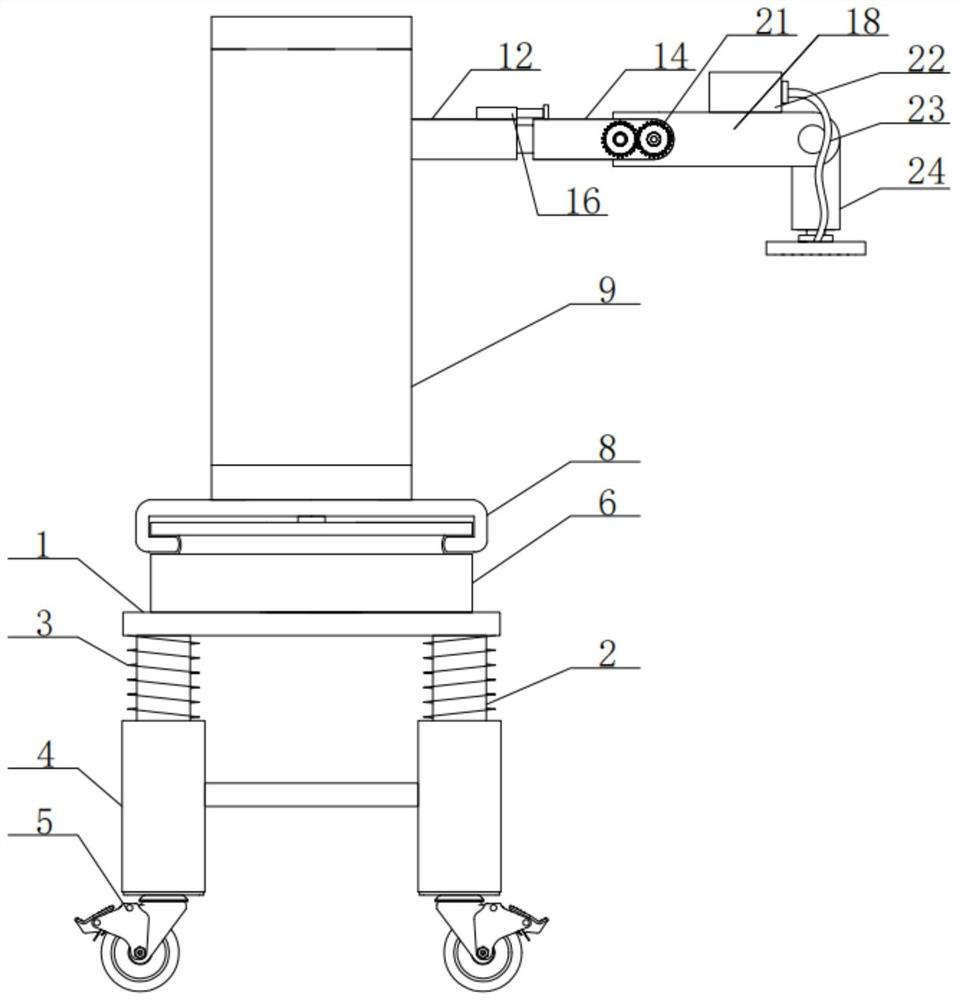

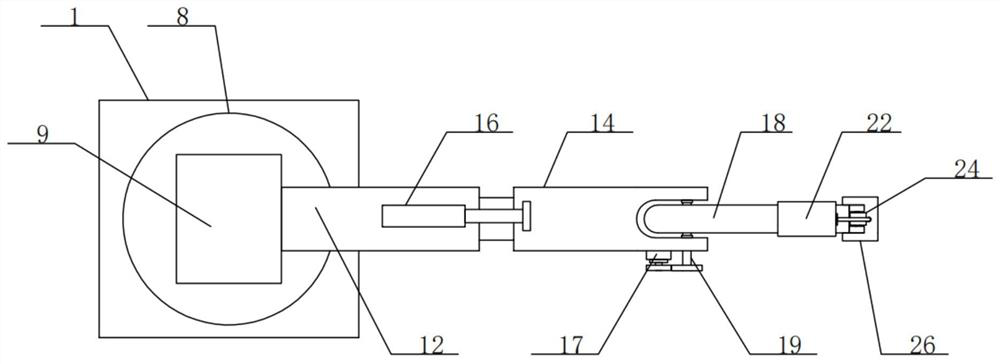

Laser welding feeding and positioning device

InactiveCN111843208AEnsure safetyImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesPhysicsElectric machinery

The invention discloses a laser welding feeding and positioning device. The device comprises a device body and a clamping mechanism; bottom brackets are connected with the bottom of the device body; atripod is arranged on the right side of the bottom brackets and a motor platform is arranged on the right side of the tripod; a motor is arranged at the top of the motor platform; bases are connectedwith the bottoms of the bottom brackets; fixed screws are arranged at the tops of the bases; a slide rail is arranged on the left side of the top of the device body; and a sliding extensible mechanism is arranged on the right side of the slide rail. Through the arrangement of the slide rail and the sliding extensible mechanism, the device body constitutes a movably upward adjustment function; inoperation of the device, vertical sliding can be realized by collaborative operation of the slide rail and a sliding plate; and with the addition of an extensible structure of an extensible pillar, aclamped workpiece can be move from left to right to a processing position, so manual operation of a worker is not required, the operation efficiency of the device is improved, and safety of the workeris guaranteed.

Owner:DONGGUAN UNIV OF TECH

Automatic edge-covering and welding process for pendant ornaments

InactiveCN111940939AIngenious process designSmooth connectionWelding/cutting auxillary devicesAuxillary welding devicesMachining processManufacturing engineering

The invention relates to an automatic edge-covering and welding process for pendant ornaments, and belongs to the technical field of pendant ornament processing processes. The automatic edge-coveringand welding process comprises the following steps of step 1, automatically feeding the pendant ornaments; step 2, automatically covering the edges of the pendant ornaments; step 3, automatically welding rolled parts of the pendant ornaments; and step 4, removing welding spots of the pendant ornaments. By means of a wrapping and inlaying mechanism, a rolling operation of metal edges arranged on theouter sides of the pendant ornaments in a sleeving mode can be achieved, so that the wrapping and inlaying operation of the pendant ornaments is achieved, and by means of a welding spot removing mechanism, a removing blade can remove the welding spots of the pendant ornaments; and under the action of a pendant ornament feeding mechanism, the pendant ornaments can be sequentially conveyed to the right side, so that a material shifting mechanism sequentially carries out feeding operation on the pendant ornaments, the process design is ingenious, procedures are smoothly connected, automatic feeding, edge covering, welding and automatic welding spot removing of the pendant ornaments are achieved, the automation degree is high, the production efficiency and the yield can be greatly improved, and the labor intensity of workers is reduced.

Owner:杨素

Machining equipment with energy-saving effect for aluminum alloy profiles for doors and windows

InactiveCN113231690AIncrease contact areaConvenient loading operationMetal sawing devicesElectric machineryDrive motor

The invention discloses machining equipment with an energy-saving effect for aluminum alloy profiles for doors and windows. The machining equipment is composed of a base, a longitudinal plate and a feeding device. A center rod is driven to rotate through the output end of a stretchable motor, and therefore the contact area with the aluminum alloy profiles is increased, and feeding operation is conveniently carried out; the output end of a feeding motor drives a supporting rod to rotate, so that a feeding block carries out pushing operation on the aluminum alloy profiles, automatic feeding is carried out, and time and labor are saved; the output end of a sliding motor drives a screw rod to rotate, so that the machining operation is conveniently carried out on the aluminum alloy profiles with different thicknesses; an arc-shaped groove is used for enabling a connecting rod to slide in the interior of the arc-shaped groove, so that the machining operation at different angles is conveniently carried out on the aluminum alloy profiles; a transmission wheel is driven by the output end of a driving motor to carry out transmission connection through a belt, and therefore machining operation of the aluminum alloy profiles is carried out. and the machining equipment can achieve automatic feeding, saves time and labor, and meanwhile can carry out adjustment according to the thicknesses and the machining angles of the aluminum alloy profiles.

Owner:曲方坤

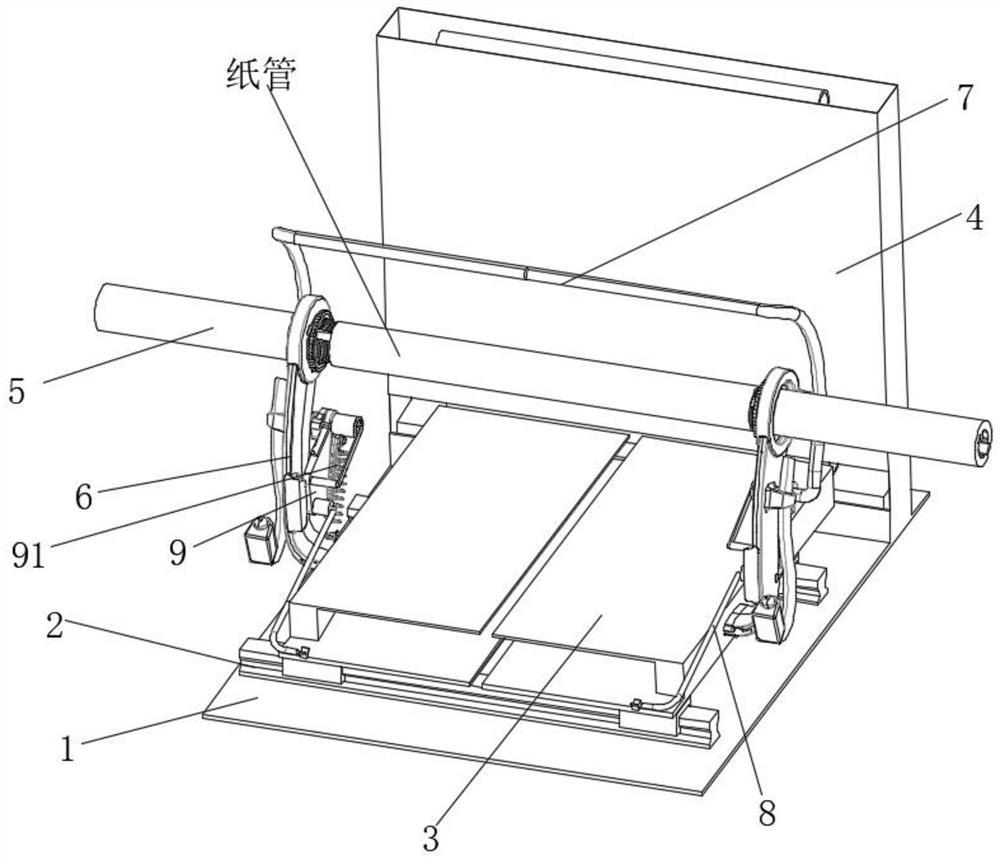

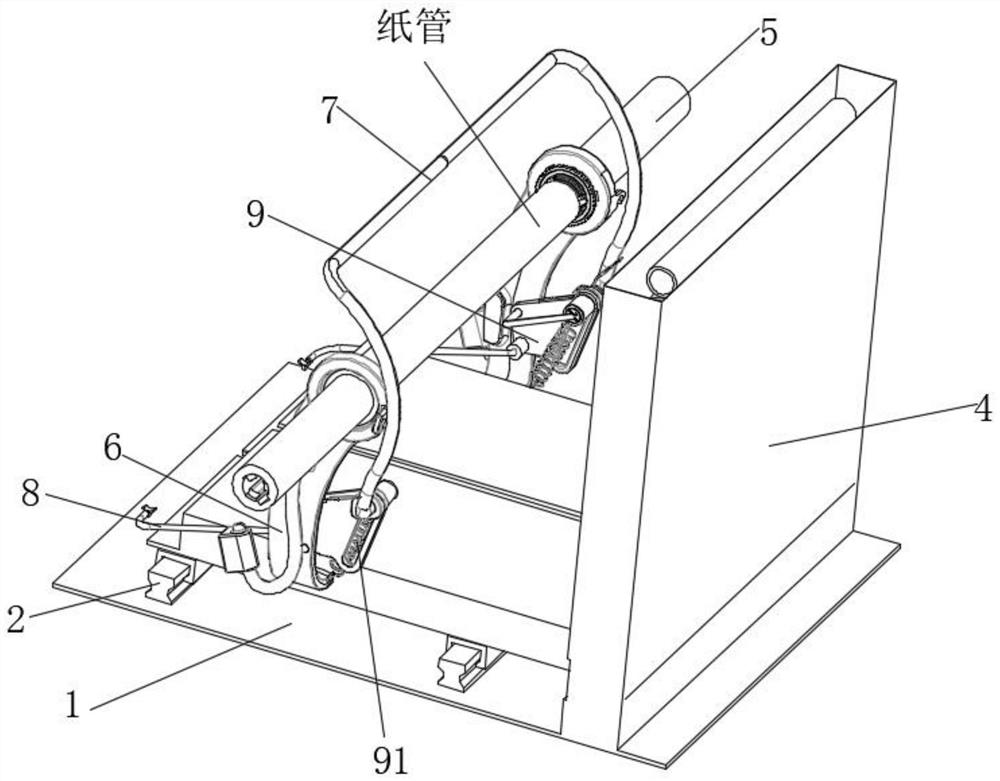

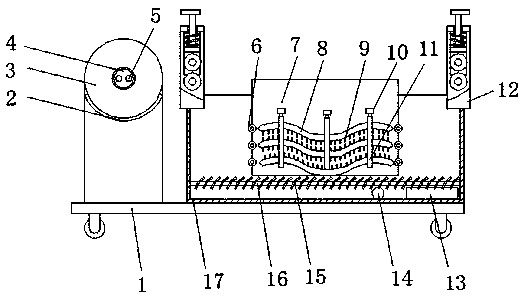

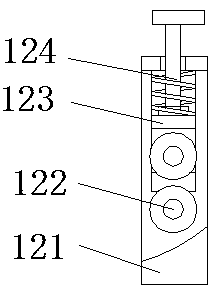

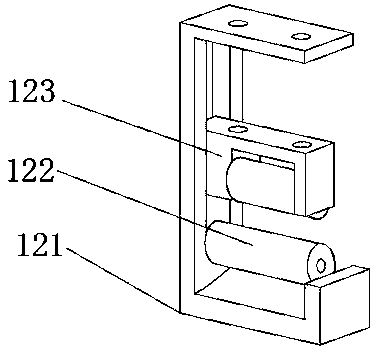

Cotton packaging film winding device with automatic feeding function

InactiveCN114436013AImprove winding efficiencySimple structureWebs handlingAgricultural engineeringScrew thread

Owner:江光保

Fire hose cleaning device

ActiveCN111359129AConvenient loading operationImprove cleaning qualityFire rescueElectric machineryDrive motor

The invention belongs to the technical field of fire fighting, particularly relates to a fire hose cleaning device. The fire hose cleaning device solves the problems that a fire hose is mainly reliedon cleaning in a water pool by firemen, the labor amount is large, water stains are prone to remaining in the cleaning process, and later use is affected. According to the technical scheme, the fire hose cleaning device comprises a base, wherein a cleaning box is fixedly installed on one side of the top of the base, a supporting frame is fixedly installed on the other side of the top of the base,a pollution discharge sealing plate and a drainage pipe are fixedly installed at the bottom of the side face of the cleaning box, and a driving motor is fixedly installed on the side face of the supporting frame. According to the fire hose cleaning device, the driving motor drives the folding position of the fire hose to be wound and pulls the fire hose to pass among three cleaning plates, the fire hose is comprehensively cleaned through the concave-convex fluctuation characteristic of the cleaning plates of a wavy structure, the side faces of the cleaning plates are in an exposed state, the bottom end of a mounting frame can be lifted away from the interior of the cleaning box, feeding operation is facilitated, falling garbage can be conveniently brushed and discharged, and the cleaning quality is improved.

Owner:邳州市景鹏创业投资有限公司

Automatic feeding machine for CPVC cable protection pipe production

InactiveCN113200281AIncrease cleaning powerConvenient loading operationPackagingSupporting framesElectric machineryProcess engineering

The invention discloses an automatic feeding machine for CPVC cable protection pipe production. The automatic feeding machine comprises a base, a first motor, an air drying mechanism and a storage box, the air drying mechanism is fixed on the upper end face of a first conveying channel, a first draining plate is arranged on the lower side of the air drying mechanism, and a water storage tank is arranged on the lower side of the first conveying channel. A water pump is fixed to the inner bottom of the water storage tank, the storage box is fixed to the right side of the upper end face of the base, a second conveying channel is fixed to the upper end face of a second draining plate, and openings are formed in the left side and the right side of the bottom of the second conveying channel. According to the automatic feeding machine for CPVC cable protection pipe production, in the process that granular raw materials roll downwards along the first conveying channel, water in the water storage tank can be sprayed out through a water passing channel and a water spraying head in sequence under the action of a water pump, the raw materials are conveniently cleaned, then a rotating brush rotates anticlockwise, the cleaning strength is conveniently enhanced, then an air spraying head sprays air downwards, and the cleaned raw materials can be air-dried conveniently.

Owner:江苏弛信管业科技有限公司

A hydraulic support steering platform

ActiveCN103195460BSimple structureReasonable arrangementMine roof supportsHydraulic cylinderControl engineering

A hydraulic support steering platform is provided with a wedge-shaped guide plate, a lifting rotation platform and a forward pulling platform which are connected. An arc convex edge and a guide post are arranged on the guide plate, a lifting rotation hydraulic telescopic arm connected with a lifting rotation sprocket is arranged in the rear of the lifting rotation platform, one end of a lifting rotation chain is connected onto the lifting rotation hydraulic telescopic arm in a positioned manner, a vertical support pulling square box and a vertical bottom lifting square box are erected on the outer side and the inner side of the forward pulling platform respectively, a hydraulic telescopic arm connected with a forward pulling sprocket is hinged to the upper ends of the support pulling square box and the bottom lifting square box, one end of a forward pulling chain is connected onto the forward pulling hydraulic telescopic arm in a positioned manner, and a front topside hydraulic cylinder and a rear topside hydraulic cylinder are hinged onto the forward pulling platform. The force application hydraulic cylinders are reasonably arranged, and the hydraulic support steering platform is simple in structure, high in force application action effectiveness and beneficial to retracement loading of a hydraulic support. The hydraulic support steering platform with the topside hydraulic cylinders is fine in stability when in use, the heights of the forward pulling platform and the forward pulling hydraulic telescopic arm can be adjusted, loading operation is facilitated, and a sprocket and chain transmission device is convenient to use.

Owner:LIAONING XINFENG MINE IND GRP CO LTD

A CNC milling machine loading and unloading manipulator

ActiveCN111390629BEasy to transportEasy to take outMetal working apparatusNumerical controlReciprocating motion

The invention belongs to the technical field of loading and unloading manipulators, in particular to a loading and unloading manipulator for a numerical control milling machine. A CNC milling machine loading and unloading manipulator, comprising a bottom plate, a support is fixedly connected to the top of the bottom plate, a conveying device is fixedly connected to the top of the support, a connecting rod is fixedly connected to the bottom end of the conveying device, and the bottom end of the connecting rod is fixedly connected to There is a material receiving block, the top of the bottom plate is fixedly connected with a feeding device, and the top of the bottom plate is fixedly connected with a storage device, the motor drives the driving wheel to rotate, and the second slider reciprocates left and right on the second sliding rod through transmission , and then push the joint through the spring, the limit block slides in the limit shell, and drives the second slide bar to move up and down, thereby driving the connecting rod to make periodic movements, which facilitates the material transportation of the device, improves the feeding efficiency of the device, and improves the feeding of the device Excellent stability, easy to take and discharge materials, and improve the feeding effect of the device.

Owner:无锡惠泉凸轮轴有限公司

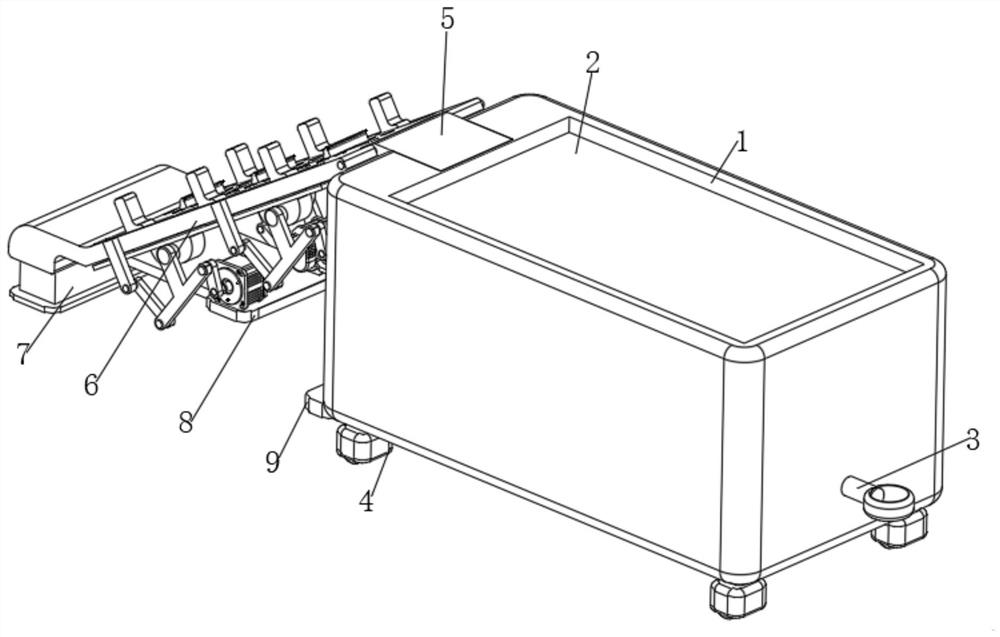

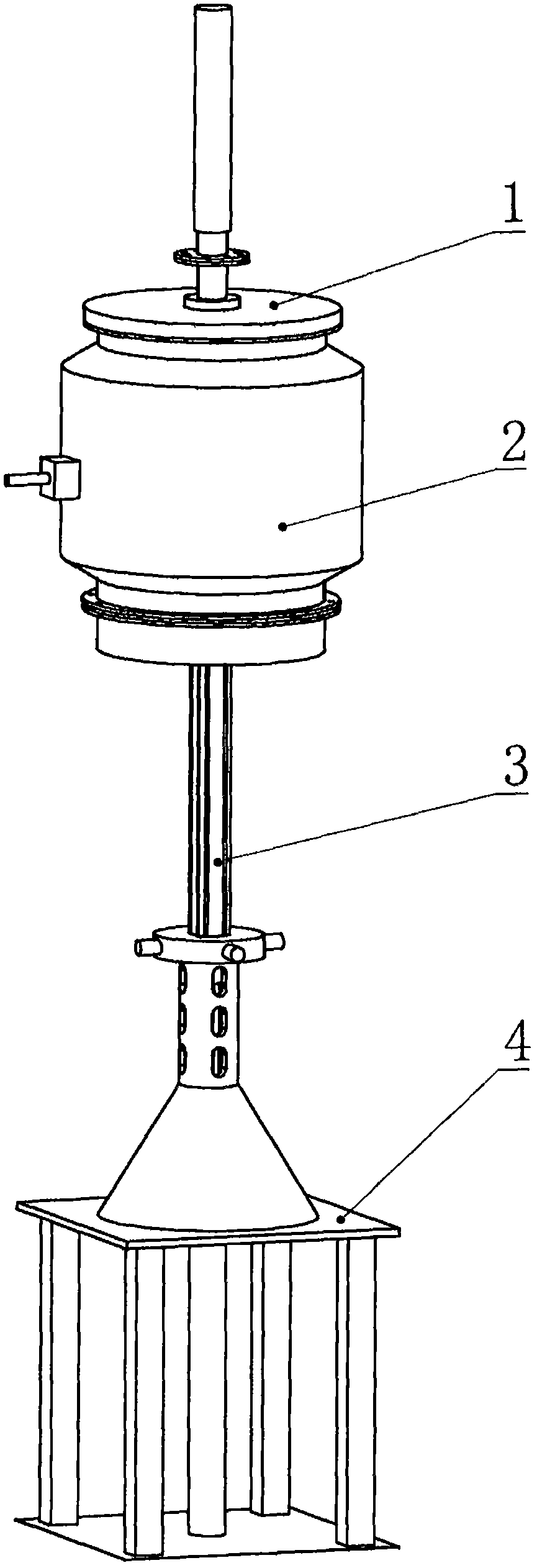

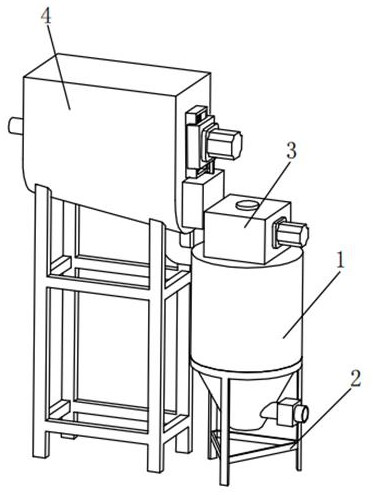

Single-cylinder ejection-type steam-explosion machine

PendingCN108783548AConvenient loading operationImprove work efficiencyFeeding-stuffEngineeringHigh pressure

The present invention belongs to the field of crop straw coarse fodder processing, and provides a single-cylinder ejection-type steam-explosion machine. The straw is subjected to steam-phase explosionpretreatment operation, and after steam explosion on the straw, the close combination of lignin, cellulose and hemicellulose is broken, so that the hydroxyl group is fully exposed, the accessibilityis increased, and the degradation rate and the enzymolysis rate of complex carbohydrates are greatly improved. After the fermentation treatment, the protein content and the absorptivity of livestock on the complex carbohydrates are improved. The machine is mainly composed of a steam-explosion buffer base, a steam-explosion cylinder body, a steam-explosion piston and a gland, and a single closed cavity is formed as a material explosion cavity in the steam-explosion cylinder. The feeding operation is convenient and fast, and the machine is high in working efficiency, simple in structure and lowin processing cost. The sealing ring is sealed by high-pressure steam body, the structure is simple, and the sealing effect is good.

Owner:内蒙古华禹高科装备科技有限公司 +1

Rapid forming die for capacitor cover plate machining

ActiveCN112157243AQuality assuranceImprove pass rateCapacitor manufactureStructural engineeringMechanical engineering

The invention discloses a rapid forming die for capacitor cover plate processing. The rapid forming die comprises a forming table. An abutting plate is fixed in the middle of the top surface of the forming table. Support columns are fixed on the top surface of the forming table. A mounting plate is fixed at the top ends of the support columns through screws. A through hole is formed in the middleof the mounting plate, and a material injection barrel barrel is fixedly connected to the inner wall of the through hole through screws. A servo motor is fixedly connected to the top face of the material injection barrel through screws. An output end of the servo motor penetrates through the top face of the material injection barrel and is fixedly connected with a material injection packing auger.A material adding hole is further formed in one side of the upper end of the material injection barrel, a material adding funnel is fixed to the inner wall of the material adding hole through screws,and first heating pipes are further arranged on the inner side of the material injection barrel. The rapid forming die for capacitor cover plate processing is reasonable in design and stable in operation, stress borne by a capacitor cover plate during chamfering die opening is reduced in a two-side die opening mode, therefore the capacitor cover plate die-casting quality is guaranteed, and the percent of pass of capacitor cover plate production is greatly improved.

Owner:宁国市红宁橡塑制品有限公司

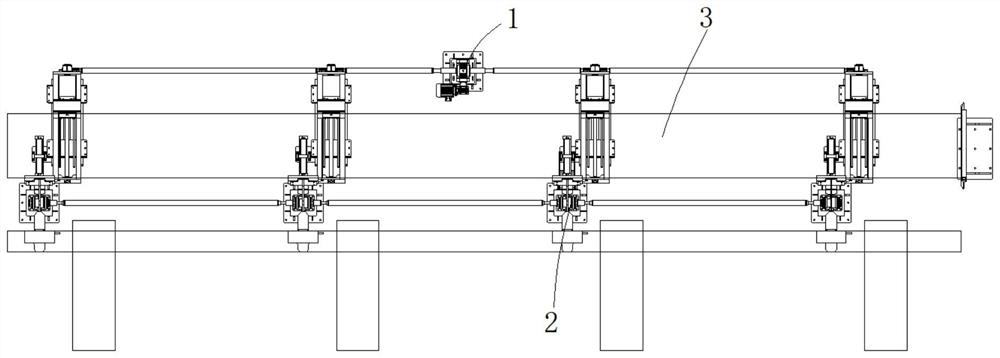

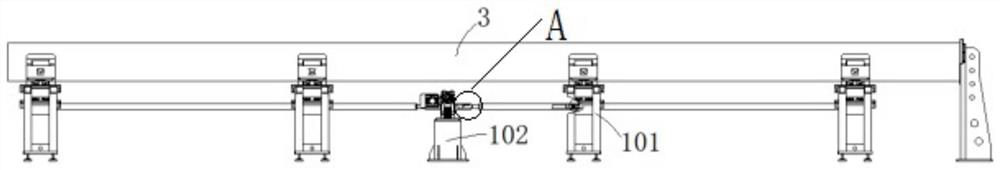

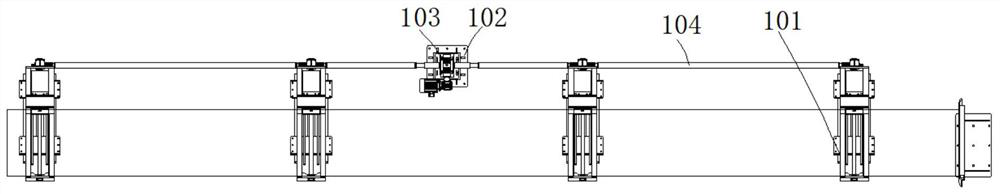

Feeding work station for detection equipment

PendingCN114751123AConvenient loading operationImprove feeding efficiencyConveyorsControl devices for conveyorsControl engineeringProcess engineering

The invention relates to the technical field of automatic feeding, in particular to a feeding station for detection equipment, which comprises a workbench, a feeding manipulator and a feeding device, the feeding manipulator and the feeding device are mounted on the workbench, and the feeding device comprises a tray transfer mechanism and a workpiece transfer mechanism; the tray transferring mechanism comprises a first linear module, a tray connected with the first linear module, a stock bin assembly located above the first linear module and a tray positioning assembly. The workpiece transferring mechanism comprises a second linear module, a third linear module connected with the second linear module, a transferring base connected with the third linear module and a position adjusting assembly installed on the transferring base. The position adjusting assembly comprises a workpiece jig base, a second power element used for driving the workpiece jig base to rotate and a third power element used for driving the workpiece jig base to move in a lifting mode. Automatic tray circulating feeding is achieved, and the feeding efficiency of small and medium-sized workpieces is improved.

Owner:东莞市竞成鑫电子设备有限公司

Continuous concrete production equipment

ActiveCN113601721AConvenient loading operationLabor-saving operationCement mixing apparatusSold ingredients supply apparatusConstruction engineeringStructural engineering

Owner:JIAXING NANFANG CONCRETE PRODS

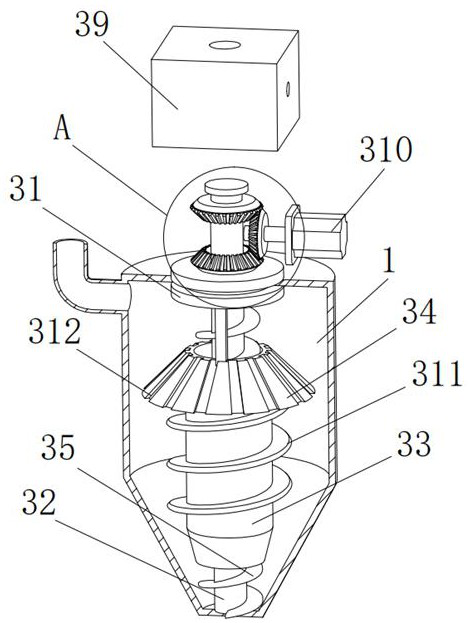

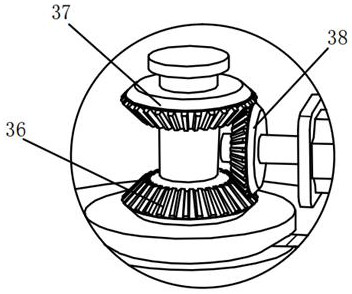

Mixing equipment for plastic colorant processing

ActiveCN113477128BAvoid technical problems that reduce productivityEvenly mixedShaking/oscillating/vibrating mixersRotary stirring mixersMechanical engineeringMixing tank

The invention discloses a mixing equipment for plastic colorant processing, which relates to the technical field of mixing equipment, including a mixing tank, a mixing bracket, a mixing part and a feeding part, and the mixing tank is arranged on a mixing At the top of the bracket, the mixing part is arranged in the mixing tank, and the feeding part is arranged on one side of the mixing tank. When the present invention works, the feeding part transports the materials into the mixing tank, and then the materials Falling to the bottom of the mixing tank, the mixing column rotates at this time, and the material is transported to the top of the mixing tube through the first mixing blade, and then the material slides down to the bottom of the mixing tank again along the distribution plate at the top of the mixing tube , working reciprocatingly in turn, the materials at the bottom of the mixing tank will be evenly transported to the top and then fall down, and the materials will be mixed evenly, which can drive all the materials to move, avoiding the technical problem of low working efficiency of the mixing equipment in the prior art.

Owner:LAIZHOU GLASS FIBER REINFORCED PLASTICS PRODS

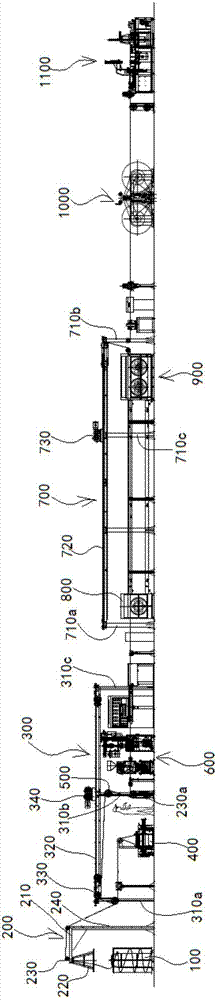

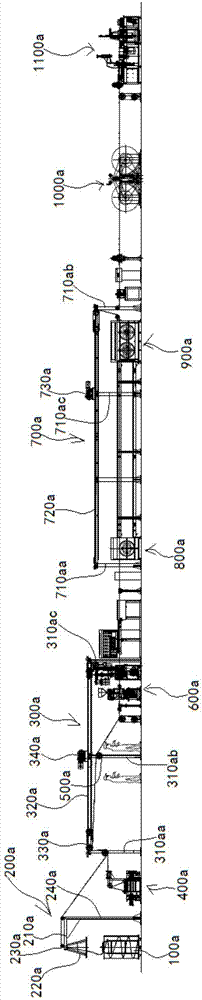

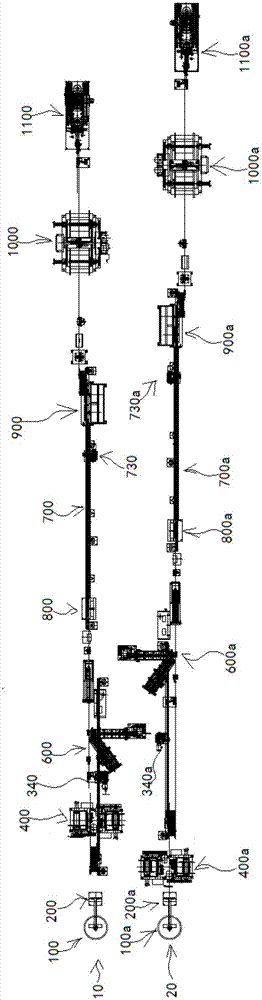

Cable factory production line layout structure

PendingCN107010468AConvenient loading operationEase of loading and unloadingApparatus for feeding conductors/cablesFilament handlingManufacturing engineeringMachine tool

The invention discloses a cable factory production line layout structure. The cable factory production line layout structure at least comprises a group of production lines, wherein the production lines comprise a first production line and a second production line; the first production line comprises a left hand machine barrel type line unwinding rack, a first line discharging rack, a first line unwinding rack, a left hand machine double-disc line unwinding disc, a left hand machine, a second line unwinding rack, a first machine tool, a second machine tool, a first line framing machine and a first line storing machine; the second production line comprises a right hand machine barrel type line unwinding rack, a second line discharging rack, a right hand machine double-disc line unwinding disc, a third line unwinding rack, a right hand machine, a fourth line unwinding rack, a third machine tool, a fourth machine tool, a second line framing machine and a second line storing machine. Through the cable factory production line layout structure, the position of a double-disc line unwinding rack is changed, so that the two production lines are not interfered with each other; the barrel type line unwinding racks are arranged in the same parallel position, so that operations of upper discs and lower discs can be facilitated; the overall layout is beautiful and elegant; operations of operators are facilitated; more positions are reserved between main machines, so that the feeding operations of the operators are facilitated.

Owner:GOLD CUP ELECTRIC APP HENGYANG CABLES

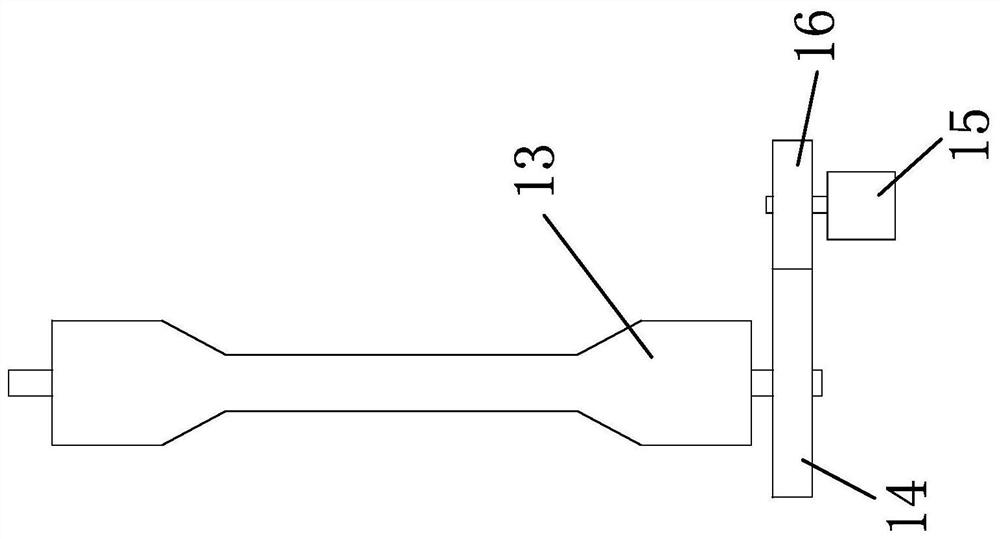

Gastrointestinal capsule pill selecting device and method

The invention relates to the technical field of pharmaceutical instruments, in particular to a gastrointestinal capsule pill selecting device. The device comprises a conveying structure, a detecting structure, a discharging structure and a collecting box, the detecting structure, the discharging structure and the collecting box are sequentially arranged in the conveying direction of the conveying structure, the conveying structure conveys capsules, and the detecting structure comprises a camera, a sensor and a controller which are electrically connected in sequence. The camera shoots the capsules, the sensor recognizes and processes images obtained by the camera and transmits image signals to the controller, the controller drives the discharging structure to discharge defective capsules, and the collecting box collects qualified capsules. The device has the effect that the defective capsules are selected more completely.

Owner:北京美宝高科技有限责任公司

High-efficiency ultrasonic vibration feeding system for diamond micropowder screening

The invention relates to a high-efficiency ultrasonic vibration feeding system for diamond micropowder screening. The high-efficiency ultrasonic vibration feeding system comprises a bearing upright post, a horizontal sliding rail, guide sliding rails, lifting driving mechanisms, a walking mechanism, a charging barrel, a guide pipe, a positioning frame, a rotary driving mechanism, a material dividing pipe, an ultrasonic vibration mechanism and a control circuit; at least two guide sliding rails are uniformly distributed on the outer surface of the bearing upright post around the axis of the bearing upright post; the horizontal sliding rail coats the bearing upright post; the charging barrel is positioned directly above the positioning frame; the guide pipe and the charging barrel are coaxially distributed; and the material dividing pipe is connected with the positioning frame through the rotary driving mechanism. On one hand, the requirement of carrying out high-efficiency feeding operation on diamond micropowder can be met effectively, and on the other hand, the stability and reliability of diamond micropowder spreading operation on a screening mechanism can be effectively improvedto prevent the screening efficiency and quality from being affected due to the excessive thickness of the accumulated diamond micropowder.

Owner:焦作天宝桓祥机械科技有限公司

A portable English multi-modal teaching device

ActiveCN111862728BEasy to pushConvenient loading operationPile receiversTeaching apparatusSoftware engineeringMaterial storage

The invention belongs to the technical field of English multi-modal teaching, in particular to a portable English multi-modal teaching device, comprising a housing, the bottom of the housing is fixedly connected with a fixing mechanism, and the bottom of the housing is slidably connected with a feeding mechanism. The inner side of the housing is fixedly connected with a conveying mechanism, the inner side of the housing is fixedly connected with a display mechanism, and the bottom of the housing is slidingly connected with a storage mechanism, which facilitates the device to carry out material loading operations, facilitates the device to push charts, and automatically operates, which is convenient for students Perform spelling or translation testing, and students can use it alone without manual auxiliary dictation, it is convenient for the device to collect and take out the chart cards, and the automatic limit code is aligned, saving time and effort, and convenient for chart cards to be reused ,easy to use.

Owner:山东新坐标书业有限公司

Assembly equipment with locating structure and for syringe processing

InactiveCN111451980AEfficient use ofFit closelyWork holdersWork tools storageButt jointRelative motion

The invention relates to assembly equipment with a locating structure and for syringe processing. The assembly equipment comprises a side top seat and a storage mechanism, and the bottom end of the side top seat is provided with a middle seat; an end chamber is formed in the middle of the middle seat, and both the upper and lower walls of the right end of the end chamber are provided with side clamping blocks; the storage mechanism is arranged in the middle of the end chamber, and the bottom end of the middle seat is fixedly provided with a footstand; and the left end of the footstand is provided with a side strip block, and the right end of the middle part of the side strip block is provided with a connecting rod in a penetrating mode. The assembly equipment with the locating structure and for syringe processing has the beneficial effects that an outer clamping head can be subjected to helical transmission through rotation of a threaded rod, so that the outer clamping head and an inner clamping head do relative motion to perform clamping treatment, thereby facilitating clamping joint operation properly; during mutual butt joint between semicircular ring structures of the inner clamping head and the outer clamping head, a syringe to be assembled can be clamped properly, thereby facilitating locating connection operation of the syringe; and the assembly equipment is high in practicability.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Automatic edge-covering and welding machine for pendant ornaments

InactiveCN111940940ARealize bezel settingFacilitate subsequent rolling operationsWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringKnife blades

The invention relates to an automatic edge-covering and welding machine for pendant ornaments, and belongs to the technical field of pendant ornament processing equipment. The automatic edge-coveringand welding machine comprises a pendant ornament feeding mechanism, a material shifting mechanism, a welding spot removing mechanism and a wrapping and inlaying mechanism; the wrapping and inlaying mechanism comprises a workbench, a welding assembly and a limiting cavity, and two symmetrically-arranged driving air cylinders are arranged at the top of the workbench; and bending blocks are fixed tooutput shafts of the two driving air cylinders, and the opposite faces of the two bending blocks are arc faces. According to the automatic edge-covering and welding machine for the pendant ornaments provided by the invention, by means of the wrapping and inlaying mechanism, a rolling operation on metal edges arranged on the outer sides of the pendant ornaments in a sleeving mode can be achieved, so that the wrapping and inlaying operation on the pendant ornaments is achieved, and by means of the welding spot removing mechanism, a removing blade can remove the welding spots of the pendant ornaments; and under the action of the pendant ornament feeding mechanism, the pendant ornaments can be sequentially conveyed to the right side, so that the material shifting mechanism can sequentially feed the pendant ornaments.

Owner:杨素

Feeding and sorting equipment

The invention relates to the technical field of slender plate processing, in particular to feeding and sorting equipment. The equipment comprises a feeding assembly, a grabbing assembly and a conveying line, the feeding assembly is fixedly connected to the back face of the conveying line, the grabbing assembly is fixedly connected to the front face of the conveying line, the grabbing assembly comprises a grabbing base, and a rotary support is arranged at the top of the grabbing base. Mounted bearings are embedded into the two sides of the interior of the rotary support, and rotary mandrels are fixedly inserted into inner rings of the mounted bearings. An air cylinder pushes a rotary arm to rotate anticlockwise, so that electromagnets make contact with a workpiece, the electromagnets are powered on to generate magnetism to suck the workpiece, the air cylinder returns to pull the rotary arm to rotate clockwise, the top of the conveying line can be conveyed to an external conveying line through the workpiece, discharging operation in slender plate machining is facilitated, the multiple electromagnets synchronously conduct adsorbing and discharging, the phenomenon of bending deformation of a slender plate due to low rigidity of the single workpiece in the discharging process can be effectively avoided, and the processing quality of the slender plate is ensured.

Owner:无锡洲翔成套焊接设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com