Feeding device of pre-warning bearing lathe

A technology of feeding device and lathe, applied in the field of bearing lathe parts, can solve the problem of early warning that the workpiece does not reach the processing position, etc., and achieve the effects of convenient feeding operation, high stability, and improved linearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

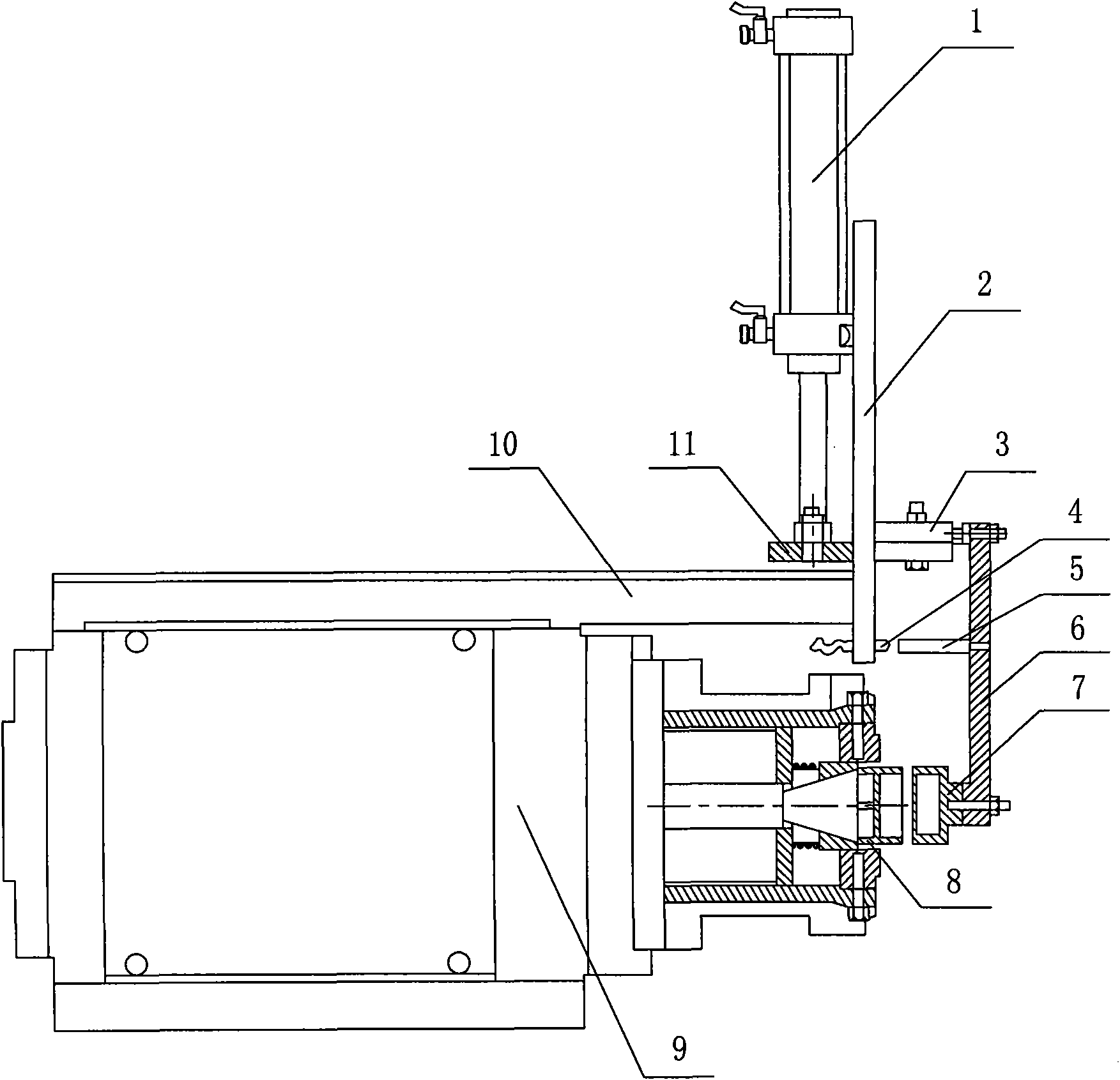

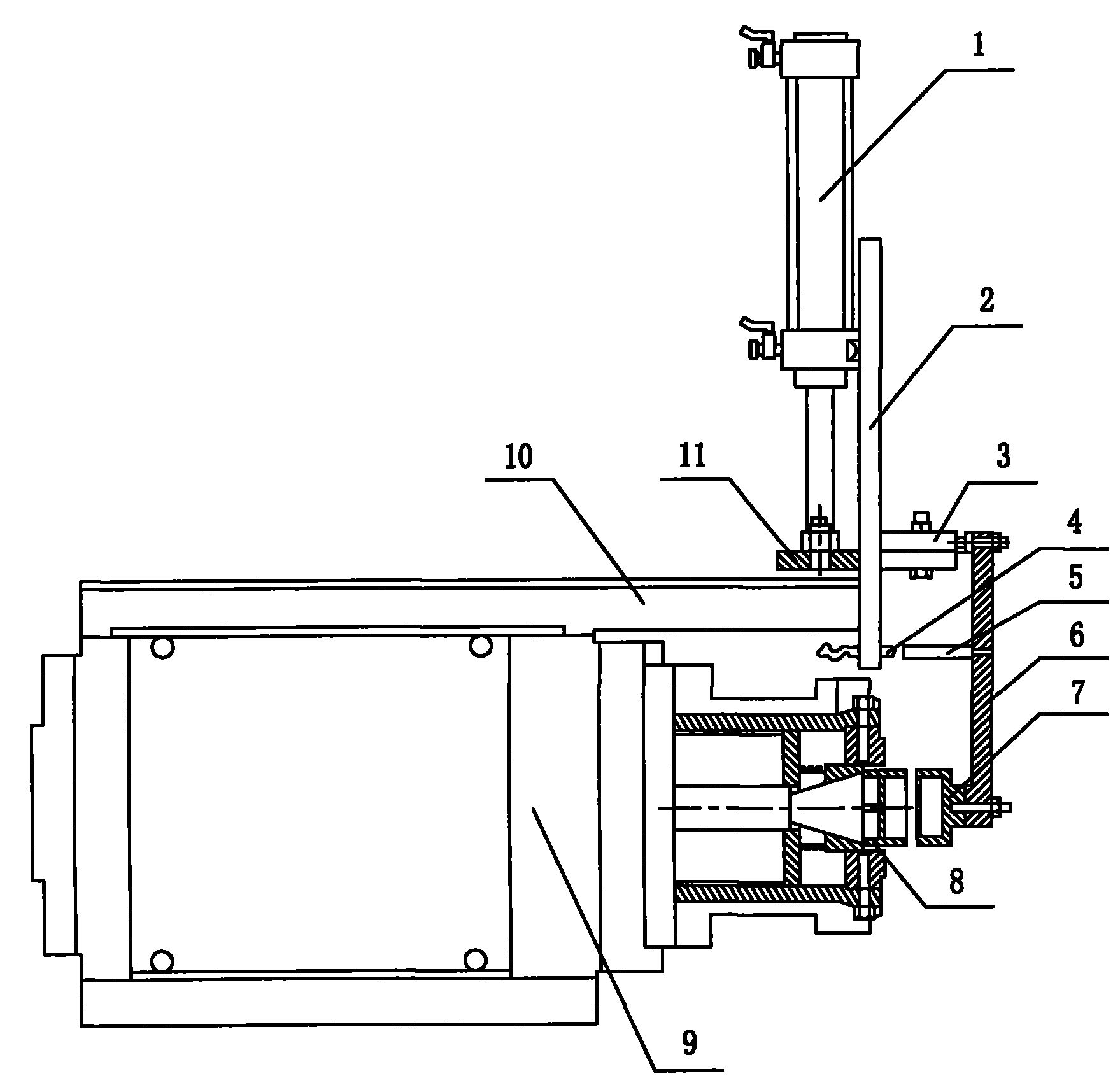

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, the present invention includes a vertical cylinder 1, a fixed plate 2, a horizontal guide cylinder 3, a connecting plate 11, a feeding detection mechanism and a material feeding mechanism, and the vertical cylinder 1 is vertically installed on the frame 10 through the fixed plate 2, The piston rod of the vertical cylinder 1 is inserted on the connecting plate 11, and the horizontal guide cylinder 3 is horizontally installed on the connecting plate 11. The feeding mechanism includes a feeding rod 6 and a feeding ring 7. The piston rod of 3 is connected, and the other end is connected with the feeding ring 7 through bolts and nuts. When the vertical cylinder 1 is in the maximum downward stroke, the clamp 8 on the main shaft of the headstock 9 is connected to the feeding ring on the feeding rod 6. 7. The feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com