Feeding and discharging manipulator for numerical control milling machine

A technology of CNC milling machine and manipulator, which is applied in metal processing and other directions, can solve the problems of inconvenient material pushing and receiving operations, inconvenient picking and unloading, and unstable use of the device. The interval between materials and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

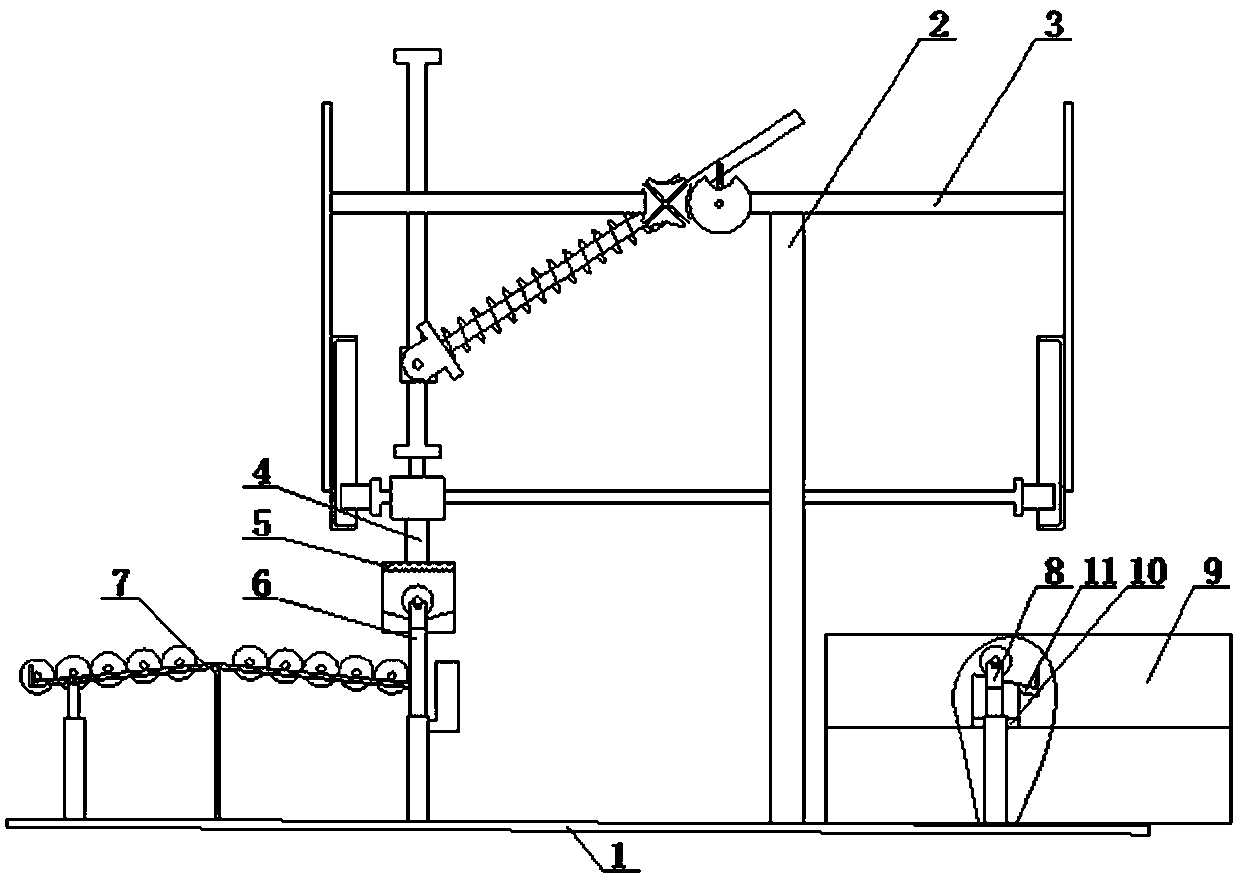

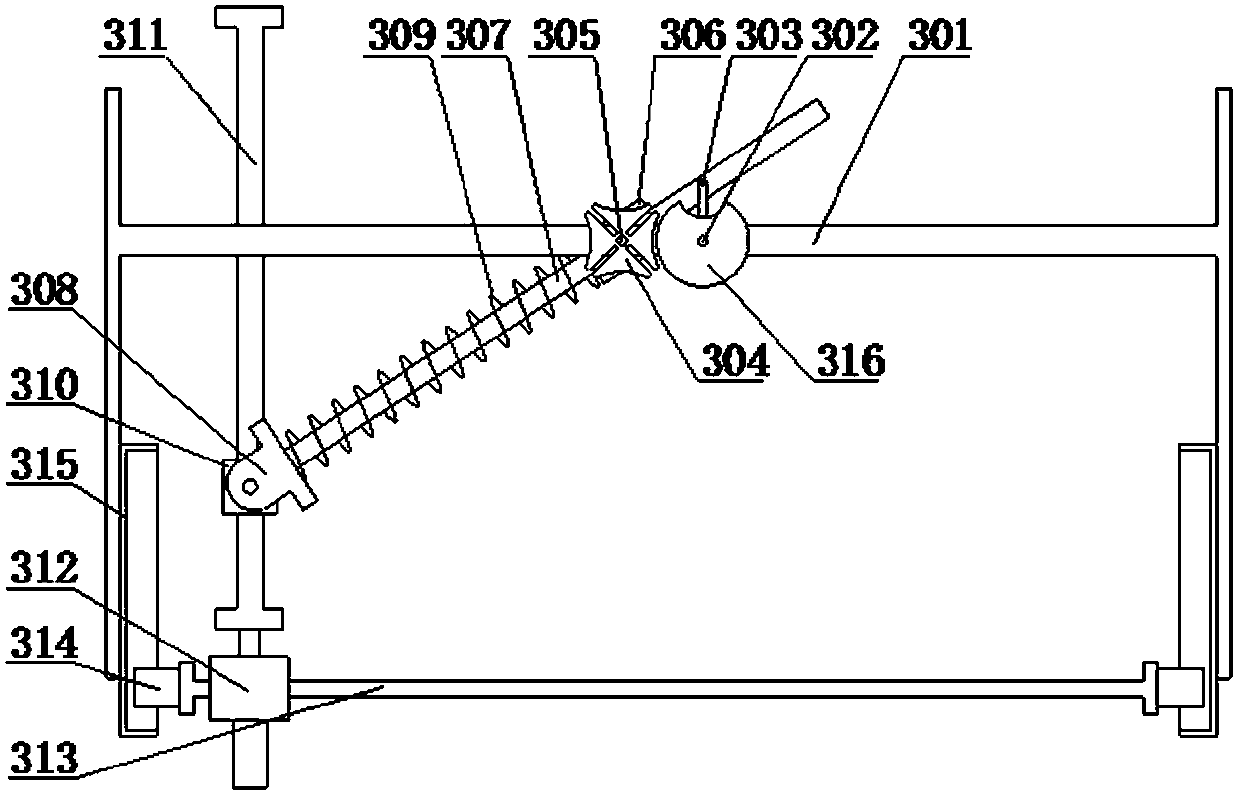

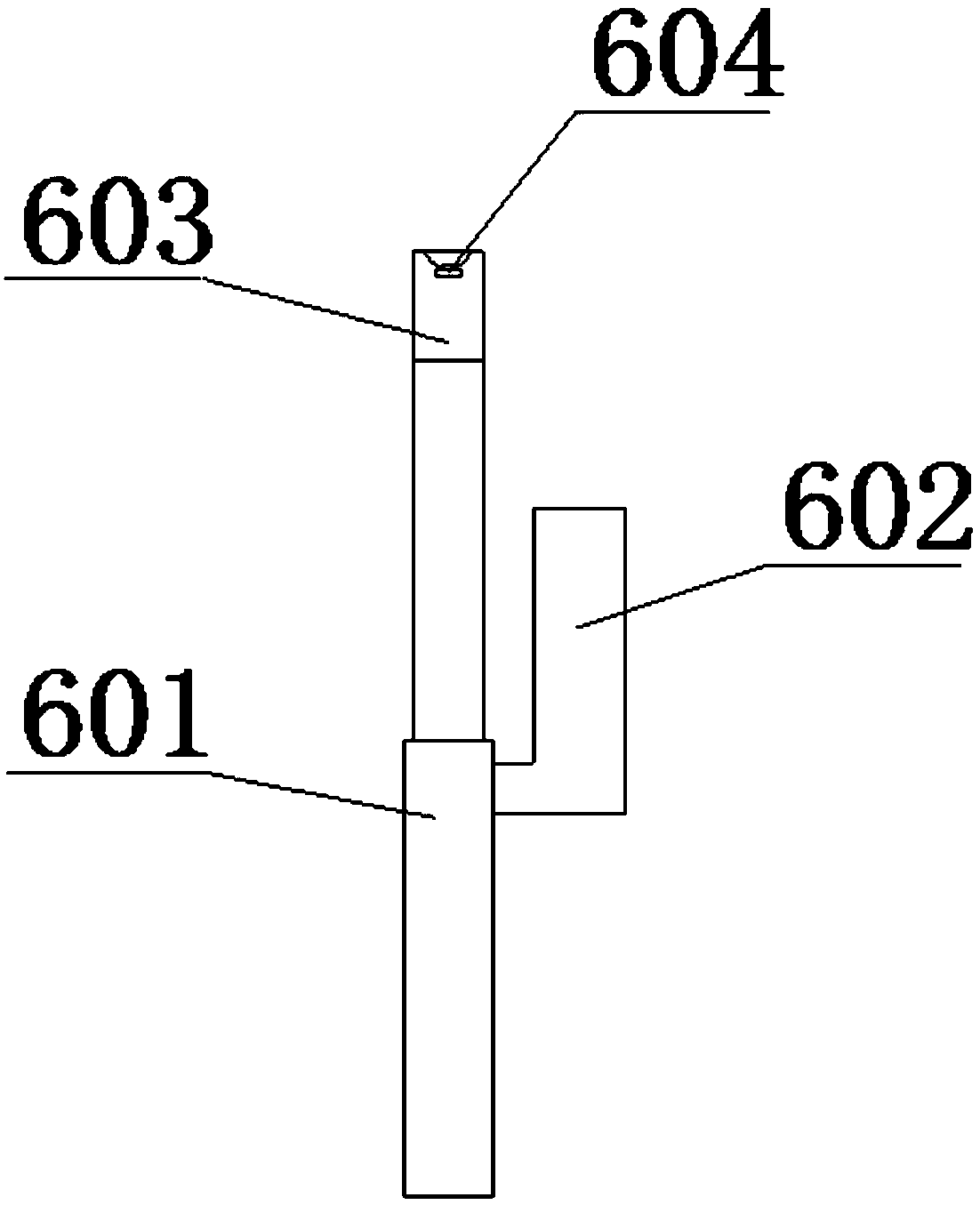

[0034] Such as figure 1 and Figure 7 As shown, a CNC milling loading and unloading manipulator includes a bottom plate 1, a support 2 is fixedly connected to the top of the bottom plate 1, a conveying device 3 is fixedly connected to the top of the support 2, a connecting rod 4 is fixedly connected to the bottom of the conveying device 3, and the bottom of the connecting rod 4 The end is fixedly connected with a material receiving block 5, the top of the bottom plate 1 is fixedly connected with a feeding device 6, the top of the bottom plate 1 is fixedly connected with a storage device 7, the top of the bottom plate 1 is fixedly connected with a CNC lathe 9, and the inner side of the CNC lathe 9 is fixedly connected with a material receiving device 8. A mounting plate 10 is fixedly connected to the inner side of the CNC lathe 9, and a receiving plate 11 is fixedly connected to the right side of the mounting plate 10.

[0035]In this embodiment: prepare the material through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com