Single-cylinder ejection-type steam-explosion machine

A catapult type, steam explosion machine technology, applied in the fields of feed, food science, application, etc., can solve the problems of hidden dangers of pathogenic infection, inconvenient transportation, low processing quality, etc., and achieves convenient and fast feeding operation, high work efficiency, Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described further according to accompanying drawing:

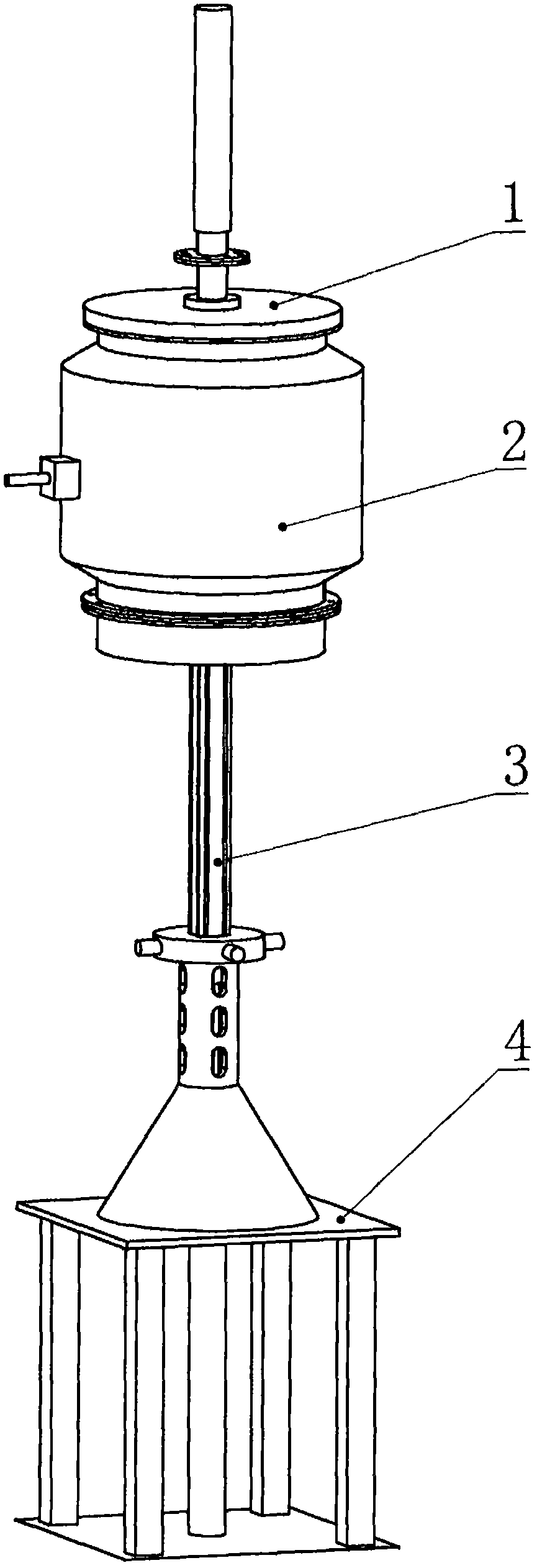

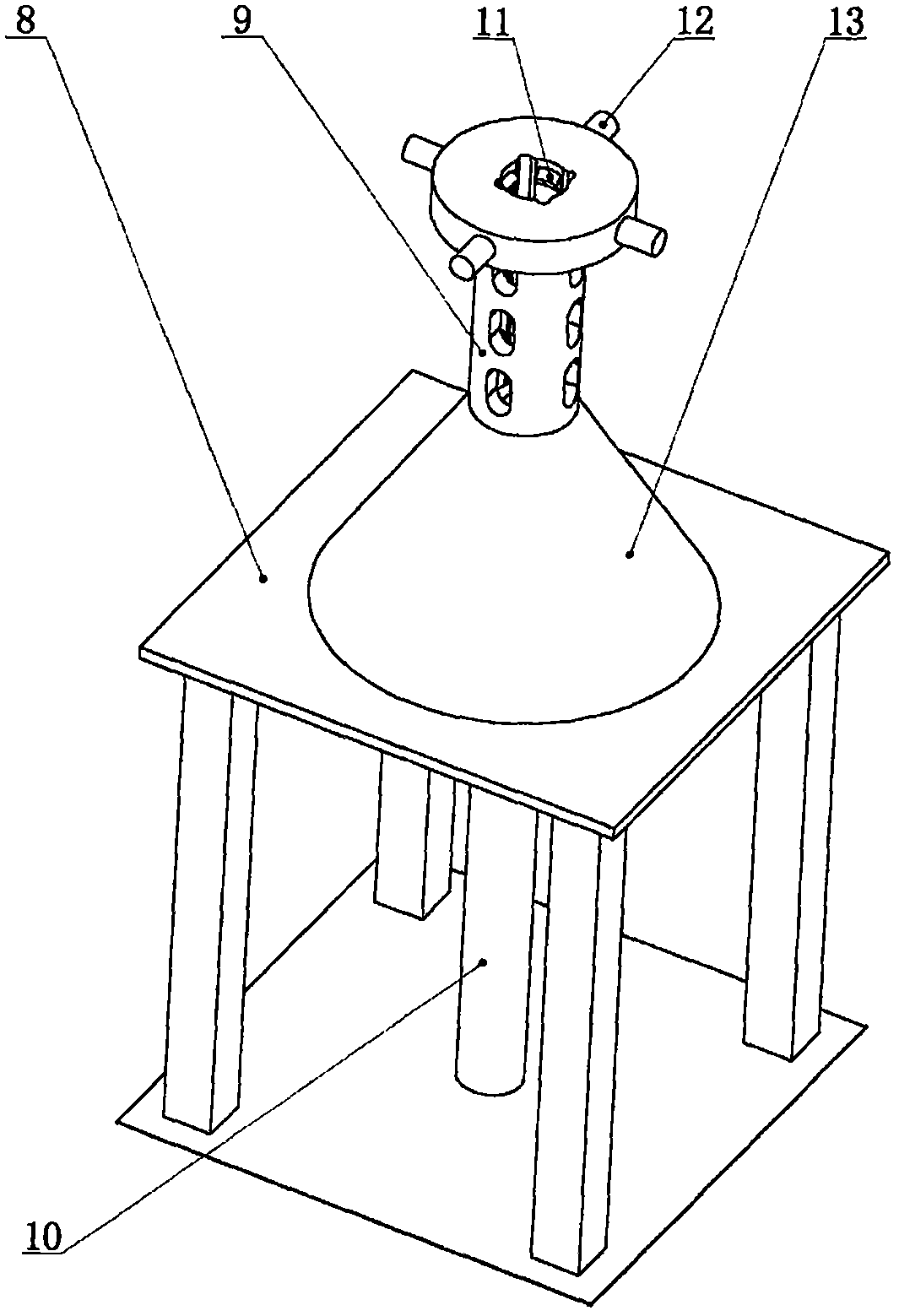

[0024] The invention relates to a single-cylinder ejection type steam explosion machine, which is mainly composed of a steam explosion buffer base 4, a steam explosion cylinder body 2, a steam explosion piston 3 and a gland 1, and the steam explosion piston 3, the steam explosion cylinder body 2 and The single airtight cavity formed by the gland 1 is the material blasting cavity 21. When the stop pin 11 on the steam explosion buffer base 4 releases the steam explosion piston 3, the internal energy of the high-pressure gas in the material blasting cavity 21 is rapidly pushed The steam explosion piston 3 moves downward, and when the sealing ring 6 of the steam explosion piston 3 leaves the lower edge of the steam explosion cylinder body 2, the material in the material explosion cavity 21 completes the steam explosion instantaneously.

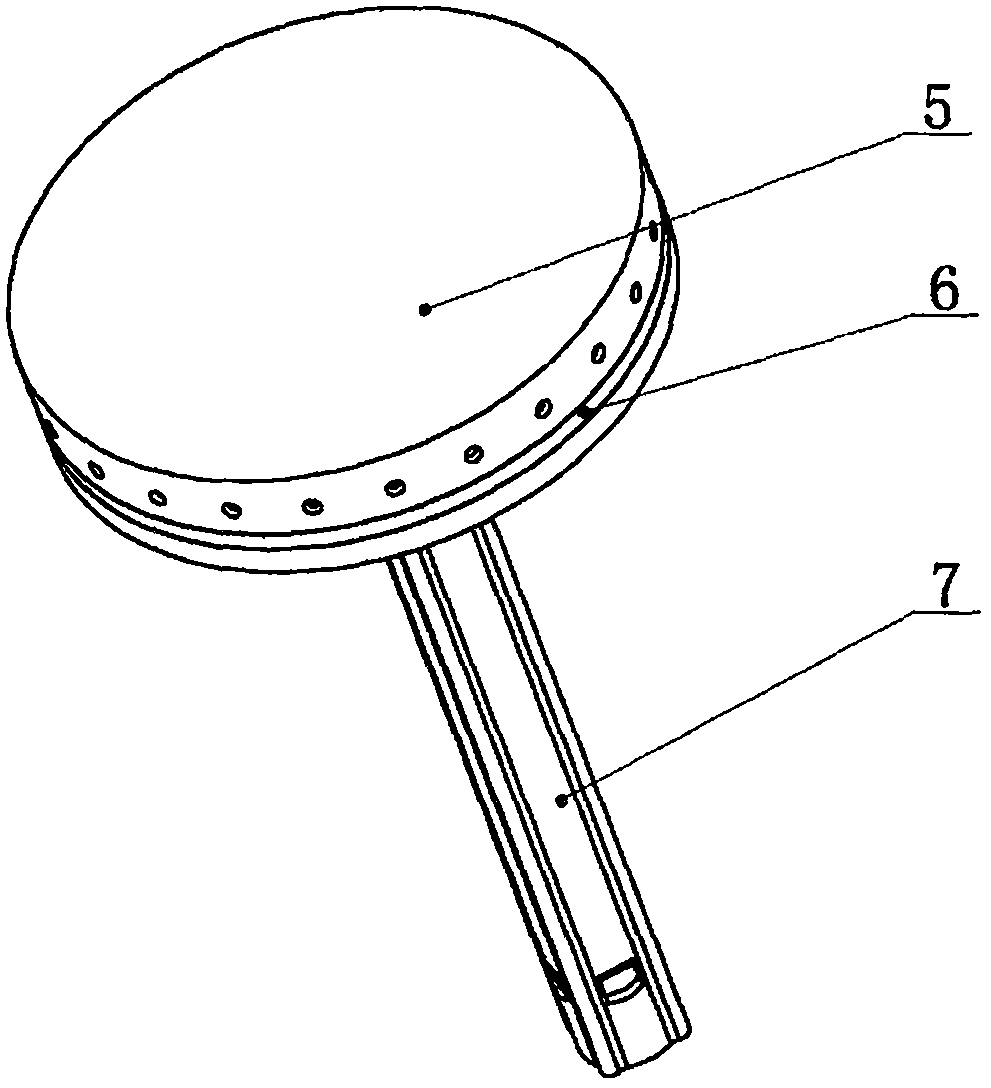

[0025] The steam explosion piston 3 mainly includes a coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com