Fire hose cleaning device

A technology of cleaning device and fire hose, applied in fire rescue and other directions, can solve the problems of easy residual water stains, heavy labor, affecting use, etc., to improve cleaning efficiency and cleaning quality, facilitate feeding operations, and improve cleaning quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

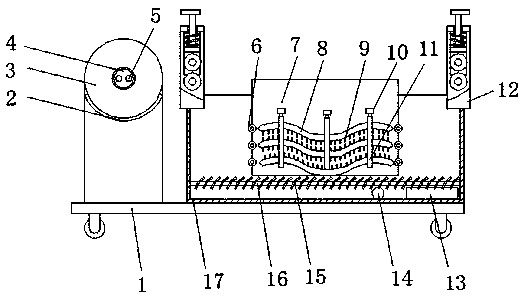

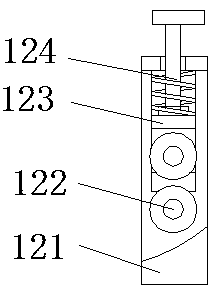

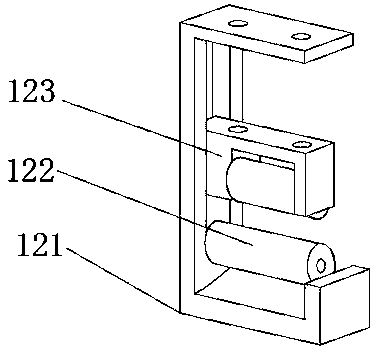

[0028] refer to Figure 1-4 , a fire hose cleaning device, comprising a base 1, a cleaning box 17 is fixedly installed on one side of the top of the base 1, and a support frame 3 is fixedly installed on the other side of the top of the base 1, and a side bottom of the cleaning box 17 is fixedly installed with Sewage sealing plate 13 and drainpipe 14, the side of support frame 3 is fixedly installed with driving motor, and the output shaft of driving motor is fixedly installed with winding mechanism, and the top both sides of cleaning box 17 is all fixedly installed with guiding mechanism 12, and cleaning The top of the box 17 is hinged with a mounting frame 7 of L-shaped structure, and the side of the mounting frame 7 is fixedly equipped with three cleaning plates 8 of wave-shaped structure, and the sides of the three cleaning plates 8 are fixedly equipped with a plurality of cleaning brushes. 9. Three limit mechanisms are fixedly installed on the side of the installation fram...

Embodiment 2

[0039] refer to Figure 1-3 and Figure 5 , a fire hose cleaning device. Compared with Embodiment 1, this embodiment also includes: an auxiliary frame 18 fixedly installed on the side of the mounting frame 7, and the bottom ends of the mounting frame 7 and the auxiliary frame 18 are fixedly installed with a row of Springs 20, the bottom end of each row of springs 20 is fixedly equipped with a support plate 21, and the tops of the auxiliary frame 18 and the mounting frame 7 are fixedly equipped with a vibration motor 19.

[0040] In this embodiment: during the cleaning process, the installation frame 7 is fixed on the top of the cleaning box 17 through the two support plates 21 at the bottom, the vibration motor 19 is turned on during the cleaning process, and the cleaning plate 8 is driven to vibrate, and then the cleaning brush 9 is used to Through the fire hose for effective cleaning, improve cleaning efficiency and cleaning quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com